Understanding tolerances and fit helps you determine how much variation is acceptable in a part’s size and shape, ensuring components can assemble properly without being too tight or loose. Tight tolerances improve precision but can be harder and more costly to achieve, while loose tolerances offer easier manufacturing but may compromise function. Balancing these aspects is key to quality and efficiency. Keep exploring how selecting the right tolerances impacts your manufacturing success.

Key Takeaways

- Tolerances specify allowable dimensional variations to ensure proper fit without excessive tightness or looseness.

- Understanding the type of fit (clearance, transition, or interference) helps determine acceptable tolerance ranges.

- Material properties influence tolerance control, affecting how parts maintain precision during manufacturing and use.

- Balancing tight tolerances with manufacturing capabilities prevents increased costs and production delays.

- Clear, well-defined tolerances ensure components fit correctly, function reliably, and maintain quality standards.

Have you ever wondered how parts fit together precisely in engineering and manufacturing? It all comes down to understanding tolerances and fit, which guarantee that components work seamlessly without issues. At the heart of this process is material selection, which influences how parts behave during manufacturing and in their final use. Choosing the right materials isn’t just about strength or appearance; it also affects manufacturing accuracy. Different materials expand or contract with temperature changes, so selecting materials with predictable properties helps maintain tight tolerances. When you pick materials that are stable and compatible, you minimize the risk of distortion or deformation, making it easier to achieve the desired fit. Manufacturing accuracy relies heavily on controlling these variables, so every step from raw material preparation to final assembly is carefully managed. Additionally, understanding the contrast ratio helps ensure that visual quality is maintained under different lighting conditions, which is essential for high-quality displays.

Material selection influences manufacturing accuracy by ensuring stability and predictable behavior for precise fits.

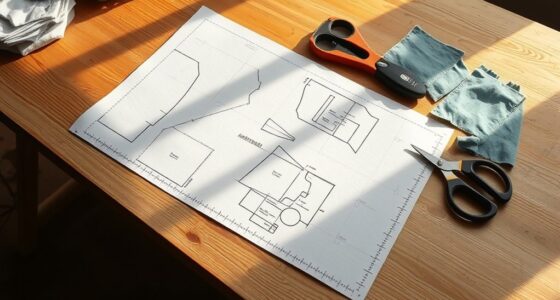

In manufacturing, tolerances define the permissible limits of variation in dimensions. They specify how much a part’s actual size can differ from its nominal size without compromising function or fit. Think of tolerances as the acceptable “wiggle room” that allows parts to fit together without being too tight or too loose. If tolerances are too tight, it becomes difficult and costly to produce parts consistently. Conversely, if they’re too loose, the assembly might lack stability or proper function. Achieving the right balance requires a clear understanding of the intended fit—whether it’s a sliding fit, a press fit, or a clearance fit—and how manufacturing processes influence the final dimensions.

To maintain manufacturing accuracy, you need to understand the relationship between tolerances and the manufacturing process itself. Processes like machining, casting, or molding each have inherent limitations and variances. By carefully designing tolerances that align with what manufacturing methods can reliably produce, you reduce rework, scrap, and delays. Precision tools, calibrated equipment, and strict quality control are crucial in this effort. When you specify appropriate tolerances during the design phase, you ensure that parts will fit together as intended, even with slight variations. This proactive approach helps prevent costly errors and ensures that the final product meets quality standards.

Ultimately, understanding tolerances and fit isn’t just about meeting specifications; it’s about creating reliable, high-quality assemblies. Material selection and manufacturing accuracy work hand-in-hand to determine how well parts fit together in real-world conditions. When you pay close attention to these factors, you’re better equipped to produce components that function perfectly, last longer, and satisfy your customers. In the end, mastering these principles leads to more efficient manufacturing processes, reduced waste, and more dependable products.

Frequently Asked Questions

How Do Environmental Factors Affect Tolerances and Fit?

Environmental factors like temperature markedly impact tolerances and fit by causing material expansion or contraction. When temperatures rise, materials expand, which can loosen fits if not properly accounted for. Conversely, cooling causes contraction, potentially leading to tighter fits or interference. You need to take into account these temperature effects during design and manufacturing to ensure parts maintain their proper tolerances and function correctly under varying environmental conditions.

What Are the Economic Impacts of Improper Tolerancing?

Improper tolerancing is like pouring money down the drain. It can lead to increased costs and decreased production efficiency, impacting your bottom line. When tolerances are off, you face costly rework, scrap, and delays, all of which eat into your profits. By ensuring proper tolerancing, you can achieve significant cost savings and streamline production, keeping your operations running smoothly and competitively.

How Do Digital Tools Assist in Tolerance Analysis?

Digital tools assist in tolerance analysis by enabling you to perform precise measurements and simulate fit scenarios using digital simulations. These tools help you identify potential issues early, ensuring parts meet specifications without costly rework. By visualizing how tolerances interact, you can optimize designs efficiently. This reduces errors, shortens development time, and improves overall product quality—making your process more accurate and cost-effective.

Are There Industry Standards for Tolerances in Specific Sectors?

Yes, industry standards for tolerances vary by sector, guiding manufacturing precision and ensuring quality assurance. You should consult specific standards like ISO, ANSI, or DIN, which set acceptable limits for dimensions and fits. These standards help you maintain consistency, reduce errors, and meet client expectations. By adhering to established tolerances, you improve product reliability and streamline quality control processes, making your manufacturing processes more efficient and compliant.

How Does Tolerance Stacking Influence Assembly Quality?

Tolerance stacking can greatly impact your assembly accuracy by amplifying manufacturing variability. When multiple parts each have slight deviations, these small differences accumulate, potentially causing misalignments or fit issues. To prevent this, you should carefully analyze how tolerances stack up during design and production, and implement strict quality controls. Managing tolerance stacking ensures your final assembly maintains the desired precision and functional integrity.

Conclusion

Think of tolerances and fit as a dance between two partners. When they move in harmony within acceptable steps, the performance flows smoothly. If one steps out of line, the whole routine falters. By understanding these boundaries, you become the skilled choreographer, ensuring every part fits perfectly, much like a well-rehearsed dance. Embrace these guidelines, and you’ll keep your projects running seamlessly, just like a flawless performance on stage.