Did you know that approximately 80% of all aluminum produced globally is used in the construction and manufacturing industries? This versatile metal is not only lightweight and durable but is also an excellent choice for creating custom aluminum screen frames. Whether you are tackling DIY projects or need precise cuts for professional applications, mastering the craft of cutting aluminum can enhance your home improvement skills immensely. With the rise of DIY enthusiasm, knowing effective cutting methods, tools, and safety measures is essential for achieving flawless outcomes.

Key Takeaways

- Aluminum is widely used in various industries, with a significant portion dedicated to construction.

- Custom aluminum screen frames can enhance the aesthetics and functionality of your home.

- Mastering aluminum cutting techniques can elevate your DIY projects.

- Understanding the right tools is crucial for effective cutting.

- Safety measures should always be a priority when handling cutting materials.

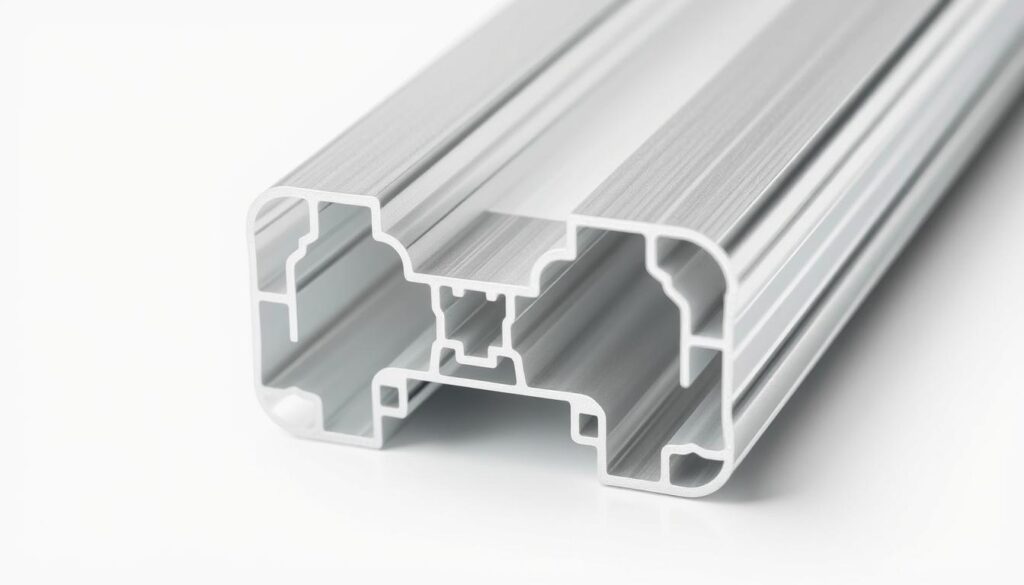

Understanding Aluminum Extrusions

Aluminum extrusion is a fascinating process involving the shaping of aluminum by forcing it through a die. This method produces an array of intricate cross-sectional shapes, making it popular in the manufacturing industry. Various aluminum profiles such as T-slot, angle, and channel are created through this precise technique.

The flexibility of aluminum allows for diverse applications, providing options that accommodate a range of design needs. Aluminum’s lightweight nature, combined with its corrosion resistance, ensures that structures like screen frames maintain durability over time. Whether you are designing a custom project or selecting standard profiles, understanding the process of shaping aluminum through extrusion opens the door to endless possibilities.

With the advancements in technology related to aluminum profiles, manufacturers can achieve exceptional accuracy and intricate designs that were once difficult to produce. This evolution not only enhances the aesthetic appeal of products but also boosts their overall functionality.

Benefits of Using Aluminum for Screen Frames

Choosing aluminum for your screen frame materials comes with numerous benefits of aluminum, particularly its impressive durability and cost efficiency. This lightweight material not only simplifies the handling process during installation or repair, but it also provides robust structural support. You will enjoy greater flexibility in design when working with aluminum, as its customizable nature allows for various styles and functions.

Another important aspect is aluminum’s resistance to corrosion. Screen frames made from this material can withstand various weather conditions, making them ideal for outdoor use. This capability enhances their lifespan significantly, ensuring that your investment remains intact for years to come without the constant need for replacement.

Aluminum’s lightweight attribute consolidates its standing as a top choice within the realm of screen frame materials. When you opt for aluminum, you engage with a solution that embodies practicality, performance, and long-lasting quality. Weighing these benefits against alternatives highlights why aluminum stands out in the market.

Tools and Materials Needed for Cutting

When it comes to cutting aluminum extrusions, selecting the right tools and materials is essential for achieving clean cuts and ensuring safety. You’ll find various cutting tools available to choose from, each serving a unique purpose during the process of aluminum cutting. Understanding these tools will significantly enhance your DIY aluminum cutting experience.

Required Tools

To begin your aluminum cutting project, gather the following necessary cutting tools:

- Miter saw or circular saw with an aluminum cutting blade

- Clamps to secure the aluminum in place

- A square for precise measuring and marking

Types of Saws for Cutting Aluminum

When selecting saw types for aluminum cutting, consider the following options:

- Miter Saw: Ideal for angled cuts

- Chop Saw: Great for straight cuts and heavy-duty use

- Circular Saw: Versatile and suitable for various angles

Safety Gear Needed

Safety should always be a priority when engaging in aluminum cutting tasks. Equip yourself with the appropriate safety gear to protect against injuries:

- Goggles to shield your eyes from metal debris

- Gloves to prevent cuts and scrapes

- A dust mask to avoid inhalation of fine particles

How to Safely Cut Aluminum Extrusions

Cutting aluminum can be a straightforward task when you implement proper safety measures. Start by securing the workpiece with clamps to ensure it doesn’t shift during the cutting process. This will help prevent accidents while using various cutting techniques.

Choosing the right blade plays a crucial role in aluminum safety. Use a blade specifically designed for cutting aluminum, as it will provide smoother cuts and reduce the risk of material tearing or warping. Remember, a dull blade can lead to overheating and compromise cutting efficiency.

Applying cutting oil can greatly enhance both your cutting process and blade longevity. This lubricant reduces friction, keeps the blade cool, and ensures cleaner cuts. Maintaining a clear working area is essential. Minimize distractions to keep full attention on your task, and be mindful of kickback zones during the cutting operation.

Effortlessly Cut Aluminum Screen Frames with These Expert Tips

When cutting aluminum, making the right choices in blade selection and lubrication can significantly impact your results. These expert tips can enhance your aluminum cutting efficiency, ensuring sharper, cleaner, and safe cuts.

Choosing the Right Blade

Your blade selection plays a critical role in achieving effective cuts on aluminum screen frames. Opt for blades specifically designed for non-ferrous metals. Such blades usually feature a higher tooth count to minimize clogging, promoting smoother cuts and reducing the risk of damaging your material. A carbide-tipped blade is often a great choice as it provides durability and sharpness, leading to precise cutting with minimal effort.

Applying Lubricants to Extend Blade Life

Incorporating suitable lubricants in your cutting process improves blade longevity and enhances aluminum cutting efficiency. Using a cutting oil or lubricant reduces friction and heat, resulting in cleaner cuts and preventing premature wear on your blade. Just a small amount applied to the blade can dramatically improve your cutting experience, helping yield better results in your projects.

Step-by-Step Guide: Amateur/DIY Cutting Method

Engaging in the cutting process of an aluminum screen frame can be both satisfying and a great way to save money. This DIY cutting guide will help you navigate the amateur methods that yield effective results.

Begin by measuring the desired length of the aluminum screen frame. Use a square to mark straight lines, ensuring accuracy in your cuts. Clamping the aluminum securely to a stable surface allows you to work without the material shifting during the cutting process.

With a hacksaw or jigsaw in hand, carefully follow the marked lines. It’s crucial to maintain a steady hand and focus on cutting straight to avoid jagged edges. This method may take patience, but a careful approach ensures clean and precise cuts.

Once the cuts are made, don’t forget to smooth out any rough edges with a file to prevent injuries during assembly. This step is essential for a polished finish on your aluminum screen frame.

In summary, using these simple amateur methods can equip you with the skills to tackle your aluminum screen frame project confidently. Embrace the DIY spirit and enjoy the process!

Step-by-Step Guide: Professional Cutting Method

For superior results in the aluminum cutting process, utilizing a professional cutting method is essential. This approach emphasizes precise tool configuration and diligent setup procedures to achieve clean cuts and a polished finish.

Setup Procedures for Professional Tools

Begin by configuring your miter saw with a specialized blade designed for non-ferrous materials. This critical step ensures that the saw handles aluminum effortlessly without causing damage. Once your blade is installed, secure your aluminum workpiece with sturdy clamps to hold it firmly in place during cutting.

Wearing the necessary protective gear, such as goggles and gloves, will safeguard you from potential hazards. Applying a lubricant to the blade can also extend its life, reducing friction during the cutting process. When executing the cut, maintain a steady pace to promote accuracy and prevent blade wear.

The following table outlines the essential elements of the professional cutting method:

| Element | Description | Importance |

|---|---|---|

| Blade Configuration | Dedicated blade for non-ferrous materials | Enhances cutting efficiency and prevents damage |

| Clamping | Use clamps to secure the aluminum | Minimizes movement during the cut, ensuring precision |

| Protective Gear | Goggles and gloves | Ensures safety during the cutting process |

| Lubrication | Apply lubricant to the blade | Reduces friction and prolongs blade life |

| Cutting Speed | Maintain a steady pace | Prevents overworking the blade and ensures clean cuts |

Common Mistakes to Avoid When Cutting Aluminum

Cutting aluminum requires precision. Avoiding cutting mistakes can lead to better quality results and a smoother experience. One common issue arises from using incorrect blades for aluminum cutting. A blade that is not designed for this material can easily break, leading to dangerous situations or incomplete cuts.

Another frequent aluminum cutting error happens when the workpiece is not properly secured. When the material shifts during cutting, it may result in uneven cuts or even injury. Ensuring that the aluminum is stable and secure protects both you and your cutting process.

Many tend to rush through the process, unaware of the implications. This practice can cause overheating, damaging both the blade and the material itself. By taking your time and utilizing proper techniques, you can significantly reduce these risks.

Ultimately, being aware of these improper techniques will improve your cutting projects, making them more efficient and successful.

Comparison of DIY vs. Professional Methods

When considering a project involving aluminum screen frames, you might find yourself weighing the options of DIY vs professional methods. Each approach presents distinct characteristics that can influence your project’s overall efficiency and quality of cuts.

The DIY method often involves simpler tools and is accessible for those with basic skills. This approach allows individuals to undertake projects at their convenience, but the finesse achieved may not match that of professional cuts. Projects that require precision face the challenges of using less specialized equipment.

In contrast, professional techniques utilize advanced machinery designed for high accuracy. These cutting methods comparison highlights the capability of professionals to handle complex jobs, delivering a superior quality of cuts that can satisfy demanding specifications. For larger or more elaborate projects, a professional’s services may significantly enhance efficiency.

Ultimately, the decision between DIY vs professional methods will depend on your specific needs and project scope. Understanding the differences can lead to a more informed choice and better results on your aluminum screen frame project.

| Aspect | DIY Method | Professional Method |

|---|---|---|

| Tools Used | Basic tools and saws | Specialized cutting machinery |

| Skill Level | Basic skills required | Advanced technical skills necessary |

| Quality of Cuts | Potentially lower precision | High accuracy and precision |

| Project Scope | Best for small, simple tasks | Ideal for large and complex projects |

| Cost | Generally lower cost | Higher cost for specialized services |

Conclusion

Mastering aluminum cutting techniques is essential for any DIY enthusiast, especially when it comes to creating custom screen frame solutions. You’ve learned the benefits that aluminum extrusions offer, as well as the essential tools and safety precautions needed to ensure a smooth cutting process. This aluminum cutting summary emphasizes the importance of understanding your options, whether you choose to take the amateur DIY route or opt for professional methods.

As you tackle your next project, remember that the right approach can significantly enhance your efficiency and the overall quality of your work. Embracing these cutting techniques will empower you to design unique and functional screen frames tailored to your specific needs. By combining proper techniques with the right tools, you’re well on your way to becoming proficient in aluminum cutting.

Ultimately, each successful project will contribute to your confidence and skillset, allowing you to explore even more ambitious DIY projects in the future. So, gather your tools, follow the guidelines, and feel secure in your ability to craft remarkable aluminum screen frames. Happy cutting!