When choosing between chasing and tapping on a lathe, consider the thread type and material. Chasing involves manually cutting precise threads with a single-point tool, ideal for custom or fine threads. Tapping uses a threaded tool or tap, best for quick, consistent threads in softer materials. Chase gives you control and accuracy, while tapping speeds up production. If you want to explore how material selection and tooling influence both methods, keep going for more insights.

Key Takeaways

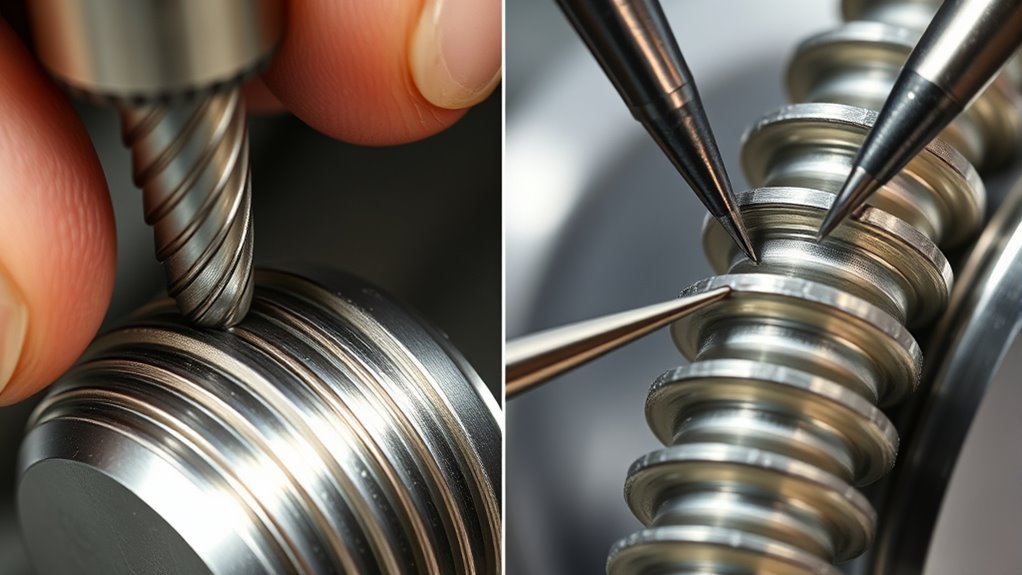

- Chasing involves cutting internal or external threads with a single-point tool on a lathe, offering precision and control.

- Tapping uses a tap tool to cut threads inside holes, typically performed after drilling.

- Chasing is suitable for custom, fine, or detailed threads, while tapping is faster for standard threaded holes.

- Tapping requires pre-drilled holes and can be easier for beginners; chasing requires skill with tool setup.

- Choice depends on thread type, size, required accuracy, and whether the thread is external or internal.

Have you ever wondered how to create precise internal or external threads on a workpiece? Mastering threading on the lathe involves understanding the importance of material selection and tool geometry. When choosing your material, you need to consider the workpiece’s properties, such as hardness and machinability. Softer materials like aluminum or brass are easier to thread, while harder metals like stainless steel require more robust tools and specific techniques. The right material selection ensures smoother cuts, reduces tool wear, and helps achieve accurate threads with minimal effort. Additionally, understanding the GMC tuning process can help optimize your machine’s performance for better threading accuracy and efficiency.

Tool geometry plays a crucial role in threading because it directly influences the quality of the cut and the longevity of your tools. A well-designed thread-cutting tool has a precise rake angle, clearance, and edge sharpness tailored to the material you’re working with. For softer materials, a sharper tool with a steeper rake angle can produce cleaner threads quickly. Conversely, harder materials benefit from tools with a more robust geometry, such as a reinforced cutting edge and a less aggressive rake to withstand the increased forces. The tool’s shape also determines how well it can produce the thread profile, ensuring consistent pitch and depth.

When setting up for threading, pay close attention to the tool’s geometry. Properly ground tools with the correct angles help prevent chatter, reduce tool wear, and improve surface finish. You’ll want to match the tool’s geometry to the material you’re machining; for instance, a single-point tool with a specific profile can produce precise threads if ground correctly. Additionally, the tool’s rake and relief angles are essential for controlling chip formation and heat dissipation, especially in tougher materials.

GBJ Lathe Threading Tool External + Internal Threading Holder SER 1010H11+ SNR 0010K11 Threading Holder with 11ER AG60 11IR AG60 Threading Inserts (SER1010H11+SNR0010K11+11ER A60+11IR A60 (Gold))

🎄【1】Inserts Material : Carbide inserts with CVD Coating. Coating endows inserts strong impact resistance, good versatility with high…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

What Are the Common Materials Suitable for Threading on a Lathe?

You can easily thread common materials like mild steel, aluminum, brass, and plastics on a lathe. These material types offer good machinability and produce smooth surface finishes, making threading straightforward. Soft metals like brass and aluminum are especially easy to work with, providing clean cuts and minimal tool wear. For best results, match your tooling and feeds to the material’s properties, ensuring precise threads and high-quality surface finishes.

How Do I Select the Correct Thread Pitch for My Project?

Choosing the right thread pitch for your project is like finding the perfect key for a lock. You need to match your thread pitch selection to your project specifications, considering factors like load, fit, and compatibility. Measure the pitch carefully, consult standard charts, and verify the threads will fit with mating parts. This way, your project will run smoothly without issues caused by mismatched thread pitches.

What Safety Precautions Should I Follow During Threading Operations?

During threading operations, you should always wear personal protective equipment like safety glasses and gloves to safeguard against metal shavings. Keep machine guarding in place to prevent accidental contact with moving parts. Never leave the lathe unattended while it’s running, and ensure your workpiece is securely clamped. Stay alert, follow proper procedures, and disconnect power before making adjustments to avoid injuries.

Can Threading Be Performed on a CNC Lathe, and How Does It Differ?

Yes, you can perform threading on a CNC lathe using specialized threading methods. CNC capabilities allow precise control, enabling you to execute external and internal threads with consistent accuracy. Unlike manual threading, CNC machines automatically follow programmed paths, reducing errors and increasing efficiency. You simply input the thread specifications, and the CNC handles the rest, making threading faster, more precise, and suitable for complex or repetitive tasks.

How Do I Troubleshoot Common Threading Issues on a Lathe?

Did you know that improper tool alignment causes over 60% of threading issues? To troubleshoot, first check your tool’s position and verify it’s correctly aligned. Use cutting fluid consistently to reduce heat and prevent tool wear. If threads are rough or uneven, adjust feed rates and speed. Regularly inspecting your setup and maintaining sharp tools will help you avoid common problems and produce precise threads.

Junreox 6 Pack Combination Drill and Tap Set, Professional HSS Titanium Thread Tap Drill Bit Set in SAE 6-32nc 8-32nc 10-32nc 10-24nc 12-24nc 1/4-20nc, Quick Change Screw Tapping with 1/4” Hex Shank

【ALL-IN-ONE HIGH-EFFICIENCY TOOL】 Experience seamless drilling, tapping, and countersinking with our 3-in-1 combination drill tap set. It eliminates…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Whether you choose chasing or tapping, remember you’re forging a path through metal’s silent song. Each method is a brushstroke on your craftsmanship canvas, shaping threads that echo strength and precision. Like a seasoned sailor steering turbulent waters, your skill guides the tool’s dance across the lathe’s stage. With patience and practice, you’ll craft threads that not only hold but tell a story of mastery—an intricate tapestry woven from your hands’ quiet, relentless artistry.

Indexable Lathe Turning Tool 21Pcs Kit 1/2'' 12mm Shank 7 Pcs Metal Lathe Tool Holder Set with 14 Pcs Turning Inserts for Turning Grooving Threading Boring Carbide Inserts Carbide Turning Tool

Patent Pending: Our innovative tool and package design are currently under patent application. Unauthorized copying or imitation will…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Zouzmin Lather Threading Tool Bit Set External Internal Threading Boring Bars Turning Tool Holders with 11IR AG60 16ER 16IR AG60 Carbide Threading Inserts (2pcs Boring Bars + 16ER IR AG60)

Threading boring bars tool holders–40CrMo , Widely Use, Tightly impacted bolt, simple structure, often used for small hole…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.