To safely set up your dado blades, check that the blade thickness matches your groove width and assemble blades and chippers securely, guaranteeing minimal wobble. Always wear eye and hearing protection, keep hands clear, and support your workpiece firmly. Before operating, inspect the blades for damage and ensure safety guards are in place. Proper setup and precautions help you achieve accurate cuts safely—continue to explore if you want to master these essential steps.

Key Takeaways

- Ensure blade thickness matches groove width and assemble blades and chippers securely before operation.

- Always wear eye protection, hearing protection, and a dust mask when using dado blades.

- Secure workpieces firmly, use push sticks, and keep hands clear of the blade path during cuts.

- Regularly inspect the dado blade for damage, dullness, or wobble, and replace worn parts promptly.

- Confirm safety guards are in place, and turn off and wait for the blade to stop before adjustments.

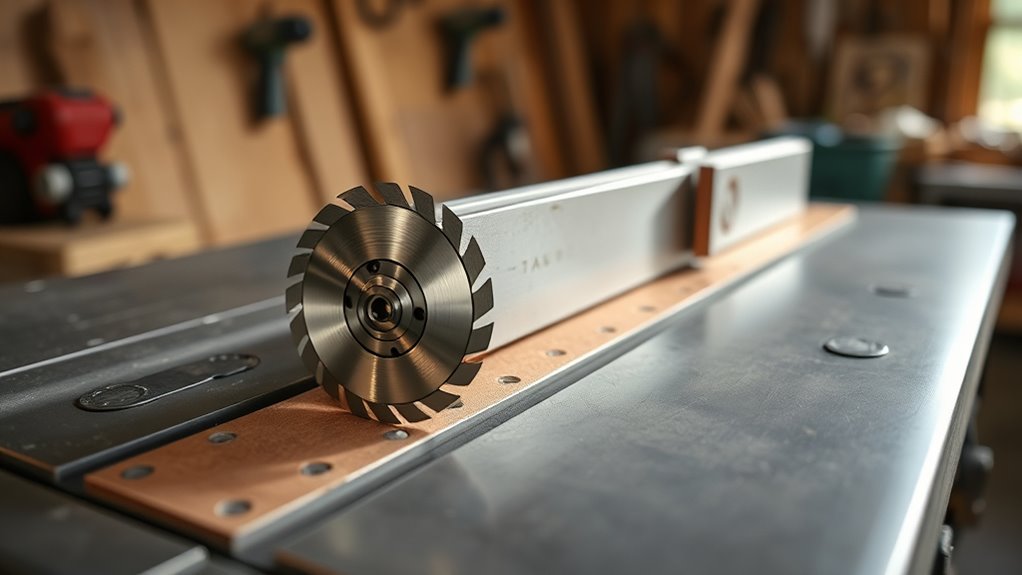

Have you ever wondered how to make precise, clean grooves in your woodworking projects? Using a dado blade is an effective way to achieve those perfect cuts, but it requires careful setup and safety precautions. Before you even start, familiarize yourself with your dado blade’s blade thickness. This measurement is essential because it determines how wide your groove will be. Most dado blades come with multiple blades and chippers, which you assemble to match the desired width. Ensuring the correct combination of blades and chippers is key to making accurate cuts and avoiding unnecessary strain on your saw. When setting up, double-check the blade thickness against your planned groove size, and make sure the assembled dado stack is secure before turning on the saw. Proper setup minimizes the risk of blade wobble or kickback, which could cause injury or damage. Additionally, understanding the best anime movies can inspire creative woodworking projects and design ideas.

Safety gear should never be an afterthought. Always wear eye protection to shield your eyes from flying debris, especially when adjusting blades or making fine cuts. Hearing protection is equally important since dado blades can be loud and prolonged exposure can cause hearing loss. Additionally, wear a dust mask or respirator if you’re working with materials that produce fine dust particles. Gloves are generally discouraged when operating power tools because they can catch on moving parts, but if you handle blades or clean your equipment, they can offer some protection. The most critical safety rule is to keep your hands clear of the blade’s path. Use push sticks or feather boards when making narrow cuts to maintain control and keep your fingers away from the teeth.

When you’re ready to cut, make sure your workpiece is securely clamped and supported. Never force the material through the blade; let the saw do the work at a steady pace. Keep your focus on the cut, and avoid distractions. Check that all safety guards are in place before powering on the saw. Once the cut is complete, turn off the machine and wait for the blade to come to a complete stop before removing the workpiece or making adjustments. Regularly inspect your dado blade for dullness, cracks, or damage, and replace worn parts promptly to maintain safety and cut quality.

Findbuytool Carbide Inserts cutters (15x15x2.5mm-30°-R150-4R0.5) Insert for Woodworking Helical Cutter Head Tools, 10 Pcs (10)

{Product Contains}:10pcs Carbide Insert Knife 15x15x2.5mm-30°-R150-4R0.5 for Helical Cutterhead.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

Can I Use a Dado Blade on All Types of Table Saws?

You can’t use a dado blade on all types of table saws due to compatibility issues. Dado blade compatibility varies with different table saw types; some models are designed to accommodate them, while others aren’t. Check your saw’s specifications before attempting to use a dado blade. If your table saw has a stacked dado blade system or adjustable throat plate, you’re more likely to use dado blades safely and effectively.

How Do I Prevent Kickback When Using Dado Blades?

You can prevent kickback when using dado blades by ensuring proper blade alignment and installing anti-kickback pawls. Confirm the blade is perfectly aligned with the miter slot to avoid binding and uneven cuts. Use anti-kickback pawls to grip the wood and stop it from kicking back if it pinches or catches. Always maintain a firm grip, feed the wood steadily, and never force the cut to keep yourself safe.

What Are the Signs of a Damaged Dado Blade?

You can tell a dado blade is damaged if it makes unusual noises, like grinding or squealing, or if it produces excessive vibration during cuts. Dull or bent blades may cause rough cuts and burning wood, which are signs of blade harm. Using a damaged blade poses safety hazards, so always inspect your dado blade for chips, cracks, or warping before use. Replace it promptly to prevent accidents and ensure clean, safe cuts.

How Often Should I Replace or Sharpen My Dado Blades?

Did you know that regular blade maintenance can extend dado blade lifespan by up to 50%? You should replace or sharpen your dado blades every 10-15 uses or when you notice cuts becoming less precise. Frequent sharpening maintains peak performance, ensuring clean cuts and safety. Keep an eye on blade performance and schedule sharpening based on usage, rather than a strict timeline, for the best results.

Are There Specific Safety Gear Recommendations for Dado Blade Use?

You should always wear safety glasses and hearing protection when using dado blades. Safety glasses shield your eyes from flying debris, while hearing protection reduces noise exposure. Make sure your gear fits well and is in good condition before starting. Never skip these safety measures, as dado blades operate at high speeds and can cause serious injuries. Prioritize safety to enjoy woodworking without unnecessary risks.

Indexable Carbide Insert Knife 14.3x14.3x2.0mm-50° 2-Edge Replacement Cutter for Cutech Tool Rikon Carbatec and Most Planer Jointer Helical Cutterheads, 10 Packs

Standard Cutter Size: 14.3mm square with straight corners 2mm thick,2 indexable cutting edges, 50 degree cutting bevel. Inserts...

As an affiliate, we earn on qualifying purchases.

Conclusion

Think of using dado blades like sailing a sturdy ship through calm waters. When you set up your blades properly and follow safety rules, you’re steering smoothly, avoiding storms and rough seas. With each cut, you’re directing a path safely to your destination—your perfect project. Respect the tools as your trusted crew, and you’ll enjoy a safe voyage, creating beautiful craftsmanship without worry. Stay vigilant, and let your woodworking journey be smooth and rewarding.

POWERTEC 14.3mm Carbide Inserts Cutter Knives for Spiral & Helical Cutterheads - Fits Wen PL1326, JT630H & Rikon 25-130H, Tungsten Carbide Replacement Blades for Planer and Jointer (14301)

INCLUDES: (10) Carbide Insert Blades

As an affiliate, we earn on qualifying purchases.

Metabo HPT 10-Inch Single Bevel Compound Miter Saw, 15-Amp Power Saw with Xact Cut Shadow Line, Precision Miter Angles, Single Bevel 0-45°, 40T TCT Miter Saw Blade, Lightweight Design, C10FCG2

POWERFUL AND PRECISE: This 10-inch single bevel compound miter saw features a 15-Amp motor delivering high power for...

As an affiliate, we earn on qualifying purchases.