Choosing between painting and staining depends on your surface type, desired look, and durability needs. If you want a uniform color with extra protection, paint is your best choice, especially for exteriors and areas needing weather resistance. For a natural, textured appearance that shows off the wood grain, stain is ideal. Consider project size, budget, and maintenance requirements. To find out which option suits your specific project and get professional tips, keep exploring.

Key Takeaways

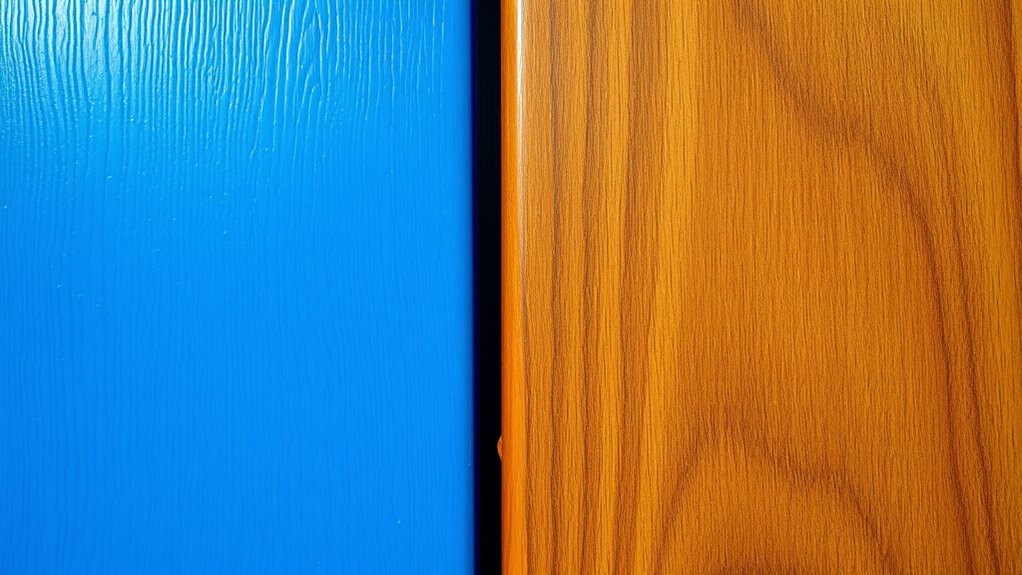

- Choose paint for outdoor surfaces needing weather resistance and uniform color, stain to highlight natural wood grain indoors or on decks.

- Consider project size and budget; stain is cost-effective for large areas like decks, while paint offers more durability for exterior walls.

- Use paint for surfaces requiring long-lasting, protective coatings; stain allows wood to breathe and shows natural texture.

- Proper surface prep is essential; paint needs priming and sanding, while stain requires only cleaning and dry surface.

- For aesthetic flexibility, paint offers a wide color palette and finish options; stain provides a natural, rustic look emphasizing wood grain.

Differences in Surface Application and Preparation

When applying paint or stain, understanding how each interacts with the surface is essential. Paint forms a thick, opaque layer that covers the substrate completely, often requiring priming and multiple coats to guarantee proper adhesion and durability. Color accuracy is more consistent with paint due to its ability to provide uniform coloration across the surface.

Stain, however, seeps into the material, especially wood, highlighting natural grain and texture with a translucent finish. Surface preparation differs: painting needs thorough cleaning, sanding, and priming, while staining usually just requires a clean, dry surface—no primer needed. If you’re switching from paint to stain, you’ll need to strip the surface back to bare material.

Both methods demand clean, dry surfaces for ideal results. Proper surface preparation ensures adhesion, appearance, and longevity, making the right choice dependent on your surface and desired finish.

Cost and Material Availability Considerations

Cost and material availability play a significant role in choosing between paint and stain for your project. Stain typically costs between $20 and $90 per gallon, making it more affordable for large areas like decks, which range from $20 to $35 per gallon. Additionally, stain is widely available in various colors and sheens, especially for natural wood finishes, while paint offers a broader color palette and customization options. The availability of stain and paint varies regionally, potentially affecting project timelines. For small projects, stain tends to be more cost-effective, whereas larger projects might justify the higher cost of paint for its durability and finish quality. The drivetrain components involved in applying each finish can influence the ease of use and final appearance. Additionally, permits and inspections are important considerations when planning your project, as they can impact material choices and timelines. Considering regional supply chains can help ensure you have the necessary materials when needed. Furthermore, understanding the application techniques for each finish can influence the overall result and longevity of your project.

Protective Qualities and Durability Factors

Protective qualities and durability are essential factors to contemplate when choosing between paint and stain for your project. Paint creates a strong, moisture-resistant surface, especially oil-based options, and offers excellent UV protection, helping colors stay vibrant longer. It generally lasts up to 10 years with less frequent reapplication and covers imperfections effectively. A key benefit of paint is its ability to cover imperfections, providing a smooth finish that enhances the appearance of surfaces. Additionally, many paints are formulated with durability-enhancing additives that improve their resistance to chipping and peeling over time. Stains penetrate the wood, becoming part of it, which offers natural protection and highlights the wood’s beauty. Solid stains provide high moisture and UV resistance, but stains generally need reapplication every 1 to 8 years. Regular maintenance can extend the lifespan of stained surfaces, although they may require more frequent reapplication. Many stains are designed to be easy to apply, making DIY projects more straightforward. While paint tends to be easier to clean and maintain, stained surfaces may be tougher to upkeep, especially with their matte finish. Both options offer distinct protective benefits suited to different needs.

Aesthetic Outcomes and Design Flexibility

Choosing between paint and stain not only impacts durability but also shapes the overall look of your project. Stains highlight the natural grain and texture of wood, creating a rustic, authentic appearance. In contrast, paint offers bold colors and a smooth, uniform finish, perfect for dramatic transformations.

With paint, you can select from a wide range of colors and finishes like matte, gloss, or satin, giving you more design flexibility. Stains typically limit your color options but allow the wood’s natural beauty to shine through, maintaining texture and grain visibility.

Layering stains can deepen colors, but they tend to age gracefully, blending weathering effects. Paint provides consistent color and a sleek surface, but scratches and chips are more noticeable, requiring maintenance.

Surface Types Suitable for Paint and Stain

Different surfaces require specific preparations and paint or stain types to guarantee a lasting, attractive finish. Wood surfaces accept both paint and stain; paint offers a uniform, durable layer, while stain penetrates to highlight natural grain. Latex paint works well on wood, especially for trim and woodwork, with staining ideal for preserving the natural look. Proper surface preparation is essential for ensuring the longevity and appearance of your finish on wood and other materials. Additionally, understanding surface porosity can help determine the best finish to use for each material. Concrete’s porous nature needs specialized paints like masonry or epoxy for durability, and stains that penetrate the surface. Drywall is mainly painted with latex paint, as stains don’t absorb well and may cause discoloration. Metal surfaces need rust-resistant paints and priming but aren’t suited for staining due to poor adhesion. Masonry and brick can be painted with breathable masonry paints or stained to enhance texture, provided surfaces are properly cleaned and prepared. Recognizing the unique properties of each surface helps in selecting the most suitable finish for your project. Additionally, understanding specialized coatings tailored for various materials can significantly improve the durability and appearance of your finished surface.

Time Investment and Application Effort

Applying paint or stain involves varying levels of time and effort, with preparation and execution steps differing considerably. Painting demands extensive surface prep, including sanding, priming, and filling cracks, which adds to project duration. Multiple coats are typically required, and each must dry thoroughly, extending the timeline. In contrast, staining requires minimal prep—just cleaning and drying the surface—allowing you to start quicker. Staining usually takes one or two coats and dries faster, speeding up the process. Painting needs careful technique to avoid drips and achieve an even finish, which can slow down less experienced applicators. Staining is more forgiving, often applied with casual tools, and mistakes are easier to fix. Additionally, shelf life of stains can influence the timing and planning of your project, as some stains may require prompt application after opening. Proper filtration and pump protection can also help maintain the quality of your stain or paint application, saving you time and effort in the long run.

Maintenance and Long-Term Upkeep

Maintaining painted and stained surfaces requires ongoing attention, but they differ markedly in how often and how easily they need repairs. Painted surfaces tend to peel, chip, and flake over time, needing frequent touch-ups or repainting every few years.

Re-staining is less invasive, as it’s easier and less labor-intensive, often requiring only cleaning and reapplication. Stains fade gradually, maintaining the wood’s natural texture and typically needing reapplication less often.

Both finishes require surface prep before maintenance, like cleaning or sanding. Paint offers a thicker barrier against UV rays and moisture, but can trap moisture if damaged, risking wood damage. Stain allows wood to breathe, reducing rot risk.

Best Uses and Project Suitability

Choosing the right finish depends on your specific project needs and the characteristics of the surface you’re working with.

Selecting the appropriate finish depends on your project’s needs and surface characteristics.

If you’re dealing with porous wood like softwoods or rough surfaces, staining is ideal, as it penetrates and highlights the natural grain. For smooth or previously primed surfaces, paint provides a solid, uniform coating that covers imperfections.

Indoors, stains work well on furniture and floors, showcasing wood’s natural beauty, while paint is better suited for outdoor projects like siding and fences, offering weather resistance.

Large exterior projects benefit from paint’s durability, whereas small indoor tasks may favor staining for ease and aesthetic appeal.

Consider the level of detail, desired look, and climate to determine whether stain’s transparency or paint’s opacity best fits your project. Additionally, understanding the cybersecurity vulnerabilities associated with digital tools can help protect your project data and ensure safety during your renovation process. Recognizing project-specific requirements such as moisture resistance or UV protection can further guide your choice between stain and paint.

Tips for Achieving Professional Results

To achieve professional results with paint or stain, proper surface preparation is essential. Start by thoroughly cleaning the surface to remove dirt, grease, and mildew. Using cookies responsibly ensures that your browsing experience remains secure and aligns with your privacy preferences. Sand evenly to create a smooth, absorbent base that promotes good adhesion. Fill holes and cracks with suitable fillers or wood putty to ensure a flawless finish. Remove any peeling or old paint or stain by scraping or sanding to prevent adhesion issues. Let the surface dry completely before applying your product to avoid bubbling and uneven coverage. Proper drying conditions and surface preparation techniques will ensure a professional, lasting finish. Choose high-quality brushes and rollers suited for either paint or stain, and use angled sash brushes for edges and corners. Apply in manageable sections, blending edges while wet, and use multiple thin coats for durability. Proper drying conditions and maintenance will ensure a professional, lasting finish.

Frequently Asked Questions

Can Stain Be Used on Non-Wood Surfaces?

Yes, you can use stain on non-wood surfaces, but it depends on the material. Gel stains work well on laminate, metal, and other non-porous surfaces because they’re formulated for these materials.

You’ll need to prepare the surface properly—clean it thoroughly, lightly sand to dull the gloss, and use a rag for application.

Keep in mind, stains may not penetrate like they do with wood, so sealing afterward is important for durability.

Is Painting More Environmentally Friendly Than Staining?

You wonder if painting is more environmentally friendly than staining. Generally, staining has a lower environmental impact because it emits fewer VOCs and often uses natural ingredients.

Paint, especially oil-based types, releases higher VOC levels, harming air quality and contributing to pollution.

If you choose water-based or zero-VOC options, both can be eco-friendlier, but staining typically remains the greener choice for reducing chemical emissions and environmental footprint.

How Often Should Stained Wood Be Re-Sealed?

You should re-seal stained wood every 1 to 3 years, depending on the stain type and climate. Solid stains last longer, around 5 to 10 years, while semi-transparent need reapplication every 3 to 5 years.

Keep an eye out for fading, cracking, or water penetration, which signal it’s time to reseal. Regular cleaning and inspections help you maintain protection and extend the wood’s lifespan effectively.

Which Option Offers Better UV Protection?

When considering UV protection, paint generally offers better results than stain.

Latex-based paints create a durable, reflective film that blocks UV rays effectively and last up to 10 years.

Stains, especially transparent ones, provide less UV defense and need more frequent reapplication.

Darker or solid stains improve in UV protection but still don’t match the longevity and surface barrier that paint provides.

Can You Switch From Stain to Paint Later?

They say, “Rome wasn’t built in a day,” and the same applies here. Yes, you can switch from stain to paint later, but it requires patience and proper prep.

Clean, sand, and prime the surface thoroughly to prevent bleed-through and guarantee adhesion. Take your time with each step, and you’ll achieve a durable, professional finish.

Rushing can lead to issues, so plan ahead for a successful transformation.

Conclusion

Choosing between paint and stain is like selecting the right brush for your masterpiece—you want what best brings your vision to life. Consider your surface, style, and durability needs, then pick the option that fits your project like a glove. Remember, the right finish isn’t just about looks; it’s about creating a lasting impression. So, weigh your options carefully, and let your project shine like a well-polished gem.