The future of woodworking is driven by advanced tech like CNC machines, laser cutters, and digital fabrication, making projects more precise and efficient. Sustainability becomes central as you choose reclaimed, recycled, and eco-certified materials. Design trends focus on natural textures and minimalist aesthetics, while DIY movement grows through online tutorials and community sharing. Expect innovations in engineered woods and smart tools. If you want to explore how these changes will shape your craft, there’s much more ahead.

Key Takeaways

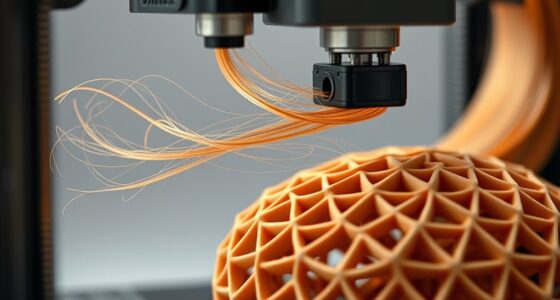

- Integration of CNC, laser cutting, and 3D printing enhances precision and customization in woodworking projects.

- Sustainable practices utilizing reclaimed, recycled, and certified materials are central to future industry standards.

- Automation and AI-driven machinery improve efficiency, accuracy, and reduce waste in woodworking processes.

- Design trends are shifting towards minimalist, organic, and biophilic aesthetics, supported by advanced engineered and composite woods.

- Digital learning platforms and maker communities foster skill development, innovation, and global collaboration in woodworking.

Embracing Advanced Technologies in Woodworking

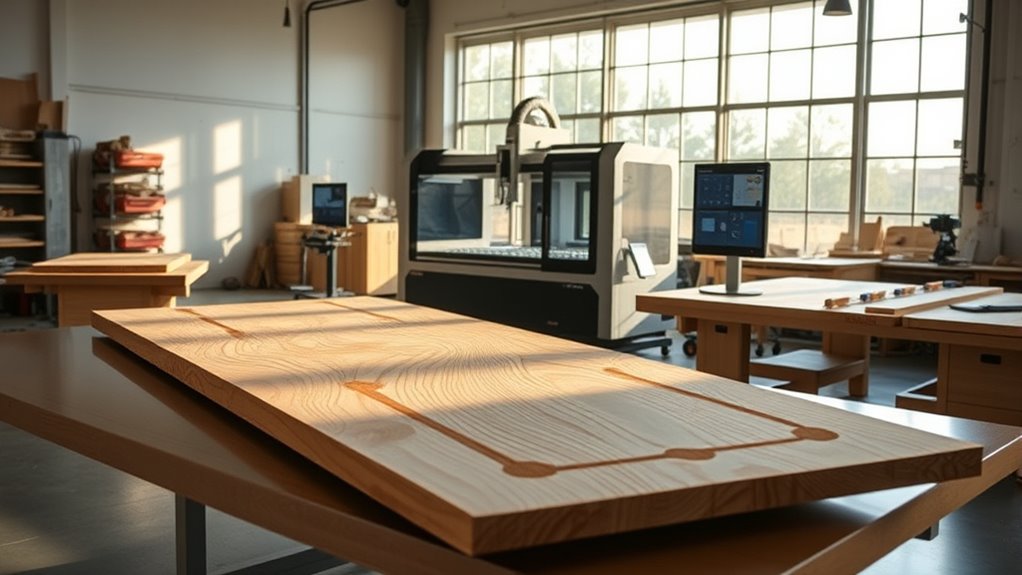

As technology continues to evolve, embracing advanced tools has become essential for modern woodworking. CNC technology offers sub-millimeter accuracy, allowing you to craft complex designs faster and with minimal waste. Digital fabrication tools like 3D printing in wood composites enable the creation of intricate, customized components that were once too costly or difficult. Laser cutting and engraving deliver unmatched precision, making detailed carving and decorative finishes easier than ever. Automation and robotics streamline repetitive tasks, boosting your shop’s efficiency and consistency. GMC tuning techniques can also be integrated to optimize machinery performance and longevity. Additionally, incorporating safety standards ensures that the use of advanced technologies remains safe for operators and complies with industry regulations. Understanding appliance power requirements is essential when integrating new equipment into a woodworking shop, especially when considering energy efficiency and safety. Staying informed about remote collaboration tools and techniques can also help you manage projects and team coordination more effectively, especially in a modern, connected work environment. Utilizing proper maintenance practices ensures that your equipment remains reliable and performs at peak efficiency. By integrating these innovative technologies, you can enhance your craftsmanship, reduce material waste, and adopt more sustainable practices. Staying ahead means leveraging these tools to improve productivity while maintaining high-quality, environmentally conscious work.

Prioritizing Sustainable Materials and Practices

You can make a real impact by choosing eco-friendly materials like reclaimed wood and certified sustainable lumber. Responsible forest management guarantees resources stay available for future projects, while non-toxic finishes improve indoor air quality. Prioritizing these practices helps create sustainable, healthier woodworking solutions.

Eco-Friendly Materials Choice

Choosing eco-friendly materials for woodworking involves prioritizing sustainable options that reduce environmental impact and promote responsible practices. Reclaimed wood offers a unique look while reducing waste, making it a popular choice. Certified sustainable lumber, guaranteed by organizations like FSC and SFI, guarantees responsible forest management and eco-friendly sourcing. Using eco-friendly finishes, such as low-VOC or non-toxic options like Rubio Monocoat, minimizes harmful emissions and improves indoor air quality. Supporting renewable resources like bamboo and recycled composites further reduces reliance on non-renewable materials. To highlight, consider this comparison:

| Material Type | Environmental Benefit | Key Feature |

|---|---|---|

| Reclaimed Wood | Reduces waste, adds character | Unique, sustainable |

| Certified Lumber | Ensures responsible sourcing | Eco-certified, sustainable |

| Recycled Composites | Utilizes waste, conserves resources | Recyclable, renewable resources |

Prioritizing these choices helps make woodworking more sustainable and eco-friendly.

Responsible Forest Management

How can woodworking benefit from responsible forest management? By supporting sustainable forestry practices that prioritize eco-friendly logging and responsible harvesting, you help protect forest health and biodiversity. Certification programs like FSC and SFI set strict standards, ensuring your wood comes from well-managed sources. Reforestation and afforestation efforts replenish harvested areas, promoting resilient ecosystems. Using reclaimed and recycled wood reduces the demand for virgin timber, minimizing environmental impact. Traceability systems allow you to verify the origin of your materials, ensuring transparency and accountability in the supply chain. Embracing responsible forest management not only aligns your projects with environmental values but also guarantees that your woodworking practices support the long-term sustainability of forests for future generations. Sustainable forestry practices are essential in maintaining healthy forest ecosystems and ensuring continuous resource availability. Incorporating environmentally responsible sourcing methods helps to reduce deforestation and supports the preservation of natural habitats. Implementing forest certification can further demonstrate your commitment to sustainable practices and reassure clients of your eco-conscious approach. Additionally, adopting innovative forest management techniques can improve forest resilience and productivity over time. Furthermore, understanding the importance of wood packaging and storage can help ensure that your materials are preserved properly, reducing waste and maintaining quality during transportation and storage.

Non-Toxic Finishes

As awareness of environmental and health impacts grows, non-toxic finishes have become essential in sustainable woodworking. These finishes, like those from Rubio Monocoat, contain zero VOCs, improving indoor air quality and supporting eco-friendly practices. Water-based stains and sealers are increasingly popular because they emit minimal VOCs and are safer for both you and the environment. Natural oil finishes derived from plant-based ingredients offer durable protection without harmful chemicals, aligning with eco-conscious goals. Using non-toxic finishes reduces the release of volatile organic compounds that can cause headaches and respiratory issues. Industry trends show a rising demand for certified, environmentally friendly products that meet strict eco-label standards. Additionally, low-VOC formulations ensure that woodworking projects meet health and safety standards while maintaining high performance. Incorporating sustainable materials not only benefits the environment but also enhances the market appeal of your work. The growing consumer interest in eco-friendly products underscores the importance of adopting environmentally responsible finishes. Moreover, advancements in biodegradable coatings are paving the way for even greener options in woodworking. Adopting these sustainable finishes helps you create healthier spaces while supporting a greener future for woodworking.

Exploring New Design Trends and Aesthetic Directions

The landscape of woodworking design is shifting as new aesthetic directions emerge, blending traditional craftsmanship with innovative technologies. You’ll see design trends that emphasize minimalist styles with clean lines and functional simplicity, creating sleek, clutter-free spaces. Customization plays a big role, thanks to CNC machining and 3D printing, allowing you to craft highly personalized wooden elements that reflect your unique style and needs. Traditional craftsmanship is making a comeback, merging artisanal techniques with modern design to produce one-of-a-kind pieces. Influenced by social media, biophilic design and organic shapes are inspiring fresh aesthetic directions, emphasizing natural forms and textures. Additionally, engineered wood like CLT and LVL is expanding possibilities in large-scale architecture, offering both strength and aesthetic versatility for bold, innovative projects. Understanding the mechanics of woodworking can further enhance your ability to innovate and adapt new techniques into your designs.

Growing the DIY Movement and Educational Opportunities

You can now access countless online tutorials, workshops, and courses that make learning woodworking easier than ever. Community-driven initiatives and maker spaces offer hands-on experience and resources to help you develop your skills. Social media platforms connect you with a global network of DIY enthusiasts, inspiring new projects and fostering growth in the movement. Additionally, the growing availability of self-watering plant pots demonstrates how innovative solutions are shaping modern gardening and DIY projects. Advances in home technology also support more efficient and customizable woodworking and gardening setups for hobbyists and professionals alike. Incorporating family photoshoot fails stories and experiences can also inspire creative and humorous elements in your DIY projects, adding a personal touch to your work. Understanding asset division laws can also be valuable if you plan to incorporate property management into your DIY projects or community initiatives. Staying informed about interior design trends can help DIYers stay current and incorporate stylish elements into their projects.

Accessible Online Resources

Accessible online resources have revolutionized woodworking education by making tutorials, project plans, and troubleshooting tips available to anyone with internet access. With digital platforms like YouTube and Instructables, you can learn new skills or refine existing ones anytime. Virtual workshops and courses from institutions such as North Bennet Street School broaden your options for e-learning, no matter where you are. These resources support your growth through:

- Easy access to a vast library of woodworking tutorials for all skill levels

- The ability to learn at your own pace via digital resources and online courses

- Opportunities to connect and share ideas through social media communities, strengthening the DIY movement

- Emphasizing the importance of woodworking materials like quality lumber and hardware to improve your projects

This shift democratizes woodworking education, empowering you to expand your craft from home.

Skills Development Communities

Growing participation in online and community-based woodworking groups has considerably expanded opportunities for skill development. You can now access community workshops and maker spaces worldwide, where hands-on training enhances craftsmanship through direct experience. These community workshops facilitate knowledge sharing among beginners and experts alike, fostering a collaborative environment for learning new techniques. Industry organizations like the Woodworking Community Network host annual events and competitions, encouraging skill development through practical challenges. The DIY movement’s growth—driven by accessible tutorials on platforms like YouTube and Udemy—supports a 40% increase in beginner projects, making skills development more approachable. Additionally, online accredited courses and certifications provide structured learning pathways, helping you deepen your craftsmanship and expand your woodworking knowledge in a community-focused setting. The availability of best airless paint sprayers and other tools further empowers hobbyists and professionals alike to refine their techniques and achieve superior results in their projects. Furthermore, the rise of online learning platforms has made expert guidance more accessible than ever, expanding educational opportunities for woodworkers everywhere. Moreover, the integration of AI technologies into instructional content is beginning to personalize learning experiences, making skill acquisition more efficient and tailored to individual needs.

Innovating With Engineered and Composite Wood Products

Innovations in engineered and composite wood products are transforming construction by offering stronger, more sustainable alternatives to traditional solid wood. These advancements include high-strength engineered wood like cross-laminated timber (CLT) and laminated veneer lumber (LVL), which enable large-scale projects such as skyscrapers and bridges. Composite wood, such as wood-plastic composites, combines recycled fibers with plastics, creating durable, low-maintenance surfaces perfect for outdoor use. To maximize these innovations, focus on:

- Improving manufacturing processes to enhance product strength and environmental performance.

- Developing new adhesives that boost fire resistance and durability.

- Expanding sustainability efforts by utilizing recycled materials and reducing waste.

These trends are shaping a future where engineered and composite woods drive sustainable, flexible, and innovative construction solutions.

Navigating Industry Challenges and Emerging Opportunities

As the woodworking industry faces supply chain disruptions and rising material costs, stakeholders must adopt innovative sourcing strategies and improve inventory management to stay competitive. Embracing sustainable materials and engineered wood products helps meet environmental regulations while expanding design flexibility. Digital technology, such as automation and AI, enhances precision and addresses labor shortages, making processes more efficient. Staying compliant with industry regulations and certifications like FSC and SFI is vital to maintain credibility and market access. Additionally, adapting to changing consumer preferences for customization and eco-friendliness requires continuous skill development and technological integration. By steering through these challenges with innovative sourcing and embracing digital advancements, you position your business for growth and resilience in an evolving industry landscape.

Envisioning the Future: Predictions for the Woodworking Sector

Looking ahead, the woodworking industry is poised to embrace a range of transformative developments that will reshape how projects are conceived and executed. You can expect increased use of engineered wood and composites, boosting durability and sustainability. Advances in automation and AI-driven machinery will enhance efficiency and precision, reducing waste. Meanwhile, smart technology and IoT will enable real-time project monitoring and customization, sparking innovation. Sustainable practices, like sourcing reclaimed and local wood, will become industry standards and consumer priorities. Ultimately, the future blends traditional craftsmanship with cutting-edge tech, creating personalized, eco-friendly designs. Here’s what’s coming:

- The integration of engineered wood will expand structural possibilities.

- Automation will streamline production while maintaining artisanal quality.

- Smart technology will foster adaptive, sustainable, and innovative woodworking solutions.

Frequently Asked Questions

How Will AI Impact Craftsmanship and Traditional Woodworking Skills?

AI will transform craftsmanship and traditional woodworking by streamlining design and precision. You’ll find tools that assist with complex cuts, pattern recognition, and quality control, making your work more accurate and efficient. While AI enhances productivity, it also offers opportunities to learn new techniques and preserve traditional skills. Embrace these innovations to expand your creative possibilities, but remember to maintain the hands-on craftsmanship that makes woodworking unique.

What Sustainable Certifications Will Become Standard in the Industry?

You’re likely to see certifications like FSC and PEFC becoming standard as sustainability gains importance. These certifications verify responsible forest management, helping you confirm your materials are eco-friendly. As industry standards evolve, you’ll probably adopt more certifications focused on environmental impact, social responsibility, and carbon footprint. By prioritizing these, you demonstrate your commitment to sustainability, build trust with clients, and stay ahead in a greener, more responsible woodworking industry.

How Can Small Workshops Adopt Advanced Digital Tools Cost-Effectively?

To adopt advanced digital tools cost-effectively, you should start small by focusing on essential software like CAD or inventory management. Look for free or affordable versions, and consider open-source options. You can also participate in online training and communities to learn best practices without high costs. Prioritize tools that improve efficiency and quality, and gradually expand as your workshop grows and budgets allow.

What Emerging Materials Could Replace Traditional Wood in Future Projects?

Have you considered how emerging materials might replace traditional wood? In the future, you could use bamboo, which’s fast-growing and sustainable, or engineered composites that offer durability and versatility. Bioplastics and recycled plastics may also become popular for eco-conscious projects. These materials can often be more affordable and easier to work with, opening new creative possibilities while reducing environmental impact. Are you ready to explore these innovative options for your next project?

How Will Regulations Evolve to Support Eco-Friendly Woodworking Practices?

You’ll see regulations increasingly supporting eco-friendly woodworking practices as governments recognize the importance of sustainability. Expect stricter rules on sourcing, encouraging the use of recycled and responsibly harvested materials. You might also encounter incentives for adopting greener methods, such as reduced taxes or grants for using eco-conscious products. These evolving policies will push you to prioritize sustainable materials and practices, ultimately helping you reduce your environmental footprint and meet consumer demand for greener options.

Conclusion

So, as you immerse yourself in this brave new woodworking world, don’t forget to embrace those flashy gadgets, eco-friendly materials, and trendy designs — all while pretending you’re revolutionizing the industry. Keep up with the DIY craze and pretend you’re saving the planet, one project at a time. After all, if you can’t innovate or adapt, at least you’ll have some pretty Pinterest-worthy pieces to show for it. Cheers to building the future — one splinter at a time.