Technology is transforming woodworking by introducing precise computer-controlled machines, allowing you to create intricate designs with ease. Innovative materials and 3D printing enable the production of complex and sustainable projects faster than ever. Digital tools help you visualize and perfect your work before cutting, while automation and robotic systems improve efficiency and safety. Eco-friendly options also support sustainable crafts. Keep exploring to discover how these advancements can elevate your woodworking skills and projects.

Key Takeaways

- Computer-controlled machinery enables precise, automated cuts and engravings, increasing efficiency and reducing human error.

- Digital design and visualization tools allow for accurate virtual prototypes, minimizing rework and optimizing material use.

- Automation and robotic assistance streamline tasks like sanding and drilling, boosting productivity and safety.

- Innovative materials and eco-friendly processes promote sustainable woodworking practices and waste reduction.

- 3D printing and advanced material processing facilitate complex, customized designs with faster prototyping.

The Rise of Computer-Controlled Machinery

The rise of computer-controlled machinery has revolutionized woodworking by enabling precise, automated cuts and engravings. CNC machines and laser cutting tools use digital files from CAD software to execute intricate designs with high accuracy. These machines rely on advanced control systems that guarantee precise digital control, reducing human error and increasing consistency. Automation allows you to produce complex patterns efficiently, whether creating one-of-a-kind pieces or large batches. The integration of digital control makes modifications easy, giving you flexibility and customization options. As a result, projects are completed faster and with greater precision, elevating the quality of your work. The use of computer-controlled machinery has also lowered the barrier to entry for hobbyists and small businesses, expanding access to high-quality woodworking techniques. This technological leap has transformed traditional woodworking into a highly efficient, scalable craft driven by digital files and sophisticated control systems. Additionally, ongoing advancements in automation technology continue to push the boundaries of what can be achieved in woodworking.

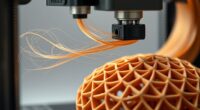

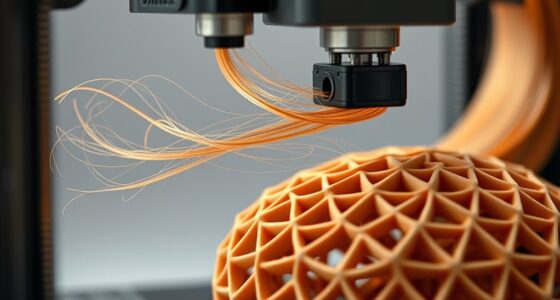

Innovative Material Processing and 3D Printing

Innovative material processing and 3D printing are transforming woodworking by allowing you to create complex, customized shapes with greater efficiency and sustainability. Using 3D printing with wood-based filaments enables precise layer deposition, reducing waste and *releasing* new design possibilities. Advanced processing techniques, such as engineered wood and eco-friendly adhesives, boost durability and promote sustainability in your projects. Combining 3D printing with traditional methods accelerates prototyping and design iterations, making it easier to develop unique furniture and decorative pieces. Innovations in laser and CNC engines enhance shaping and engraving of 3D printed components, expanding creative potential. Emerging materials like bio-composites and recycled wood filaments make 3D printing more eco-friendly and versatile, paving the way for greener, more innovative woodworking practices. Additionally, understanding the properties of beach environment such as wave and wind patterns can inspire unique surface textures and finishes in wood projects, mimicking natural erosion or driftwood effects. Incorporating digital fabrication techniques allows for even more precise and intricate designs, further pushing the boundaries of traditional woodworking.

Digital Design and Visualization Tools

Have you ever wondered how digital design and visualization tools are revolutionizing woodworking? These tools, like digital modeling and design software, enable you to create precise virtual prototypes, reducing errors and rework. Visualization tools such as augmented reality overlay digital models onto real environments, helping you assess fit and aesthetics on-site. 3D rendering allows exploration of material options, lighting, and finishes, improving project planning and client presentations. Digital prototypes support virtual adjustments, saving time and materials before building begins. Enhanced visualization tools also improve communication with clients and team members, ensuring everyone understands the design intent early. Here’s a quick overview:

| Tool Type | Function | Benefit |

|---|---|---|

| Digital modeling | Create virtual prototypes | Reduce errors, refine designs |

| Augmented reality | Overlay models in real space | Visualize fit and aesthetics |

| 3D rendering | Explore materials and finishes | Enhance planning and sales |

| Visualization tools | Communicate ideas clearly | Improve client understanding |

| Virtual adjustments | Modify designs digitally | Save time and resources |

Automation and Robotic Assistance in Workshops

Automation and robotic assistance are transforming woodworking workshops by streamlining tasks that once required extensive human effort. Robotic assistants perform repetitive functions like sanding, drilling, and assembly with high precision, boosting efficiency and reducing labor. Programmable robotic arms can handle heavy or hazardous materials, improving safety and delivering consistent results. These robotic systems operate continuously without fatigue, increasing productivity and throughput. Integration of robotic systems with CNC and other automated tools creates seamless manufacturing workflows, enabling multiple stages to occur smoothly. Plus, advanced robotic assistants are easily reprogrammable, offering versatility for different tasks and long-term cost savings. This arcade machine automation in workshops not only accelerates production but also enhances accuracy, making your workshop more competitive and adaptable to future demands.

Sustainable Technologies and Eco-Friendly Materials

As automation advances efficiency in woodworking workshops, integrating sustainable technologies and eco-friendly materials becomes increasingly important for reducing environmental impact. Using sustainable materials like engineered wood, which incorporates recycled wood fibers, promotes waste reduction and resource efficiency. Responsible sourcing from managed forests ensures replanting and ecosystem preservation. Eco-friendly adhesives, stains, and varnishes help reduce VOCs and harmful chemicals, making projects safer for both the environment and workers. Solar-powered tools decrease reliance on grid energy, lowering carbon footprints. Processing reclaimed wood with specialized tools extends material life and supports the circular economy. Incorporating self-watering plant pots as part of green initiatives demonstrates a commitment to sustainable, eco-conscious practices that benefit the environment. Additionally, implementing automated dust collection systems minimizes airborne particles, enhancing workspace safety and air quality. Embracing innovative sustainable practices can further align woodworking projects with environmental conservation goals. By prioritizing eco-friendly options and waste reduction strategies, you can make your woodworking practices more sustainable while maintaining high-quality results.

Frequently Asked Questions

How Has Technology Changed Carpentry?

Technology has transformed carpentry in many ways. You now use CNC machines for precise cuts, reducing errors and waste. Digital tools and laser measurements help plan projects more efficiently. Smart power tools with Bluetooth keep you connected and improve workflow. AR and VR let you visualize projects before building, saving time and money. Automation and robotic assistants make your shop safer, cleaner, and more productive, changing how you work every day.

What Does the Future of Carpentry Look Like?

You’re stepping into a future where carpentry combines tradition with innovation, precision with sustainability, and craftsmanship with automation. You’ll use advanced CNC machines and laser cutters for intricate designs, integrate IoT and AI for smarter workflows, and embrace eco-friendly materials for sustainable projects. Automation will handle routine tasks, making your work safer and more efficient. This blend of skills and technology will make woodworking more accessible, creative, and forward-thinking than ever before.

How Can AI Be Used in Woodworking?

You can use AI in woodworking to streamline your process and improve results. It automatically generates optimized plans, helping you reduce errors and waste. AI suggests improvements based on past projects, predicts when machinery needs maintenance, and offers real-time quality checks for imperfections. Plus, it allows for quick customization, so you can easily adapt designs to client needs and material constraints, making your work more efficient and precise.

What Technology Is Used in Carpentry?

Think of your workshop as a bustling city, where tools are your trusted citizens. In carpentry, you use technology like CNC machines, acting as precise architects, and laser cutters, like fine artisans shaping intricate details. Digital measuring devices are your mapmakers, guiding every move, while smart dust collectors serve as clean-up crews. These innovations work together, turning your craft into a futuristic city where precision, efficiency, and safety reign supreme.

Conclusion

As you embrace these groundbreaking technologies, you’re on the brink of transforming woodworking into an art form more precise and innovative than ever imagined. With every digital design, robotic assistant, and eco-friendly material, you’re shaping a future where craftsmanship reaches new heights—almost like wielding magic. The power to revolutionize your workshop lies in your hands, and the possibilities are endless, waiting for you to carve out your legacy in this awe-inspiring technological era.