3D printing with wood opens up exciting possibilities for sustainable, decorative, and complex designs by combining natural fibers with polymers or using powder bed techniques. However, it faces limitations like material brittleness, high porosity, and environmental safety concerns, especially with solvent-based binders. Advances in eco-friendly materials and improved processes are tackling these issues, making it more practical. Explore further to understand how these innovations shape the future of wood 3D printing.

Key Takeaways

- Wood 3D printing offers eco-friendly options like filament extrusion and binder jetting for decorative, functional, and complex structures.

- Incorporating wood fibers enhances mechanical properties, but current limitations include brittleness and low water resistance.

- Advances focus on sustainable, bio-based binders and recycled materials to improve environmental impact and safety.

- Challenges such as porosity, low-temperature resistance, and long curing times restrict broader industrial applications.

- Future developments aim to improve material durability, process speed, and expand uses in construction and design.

Exploring the Different Methods of Wood 3D Printing

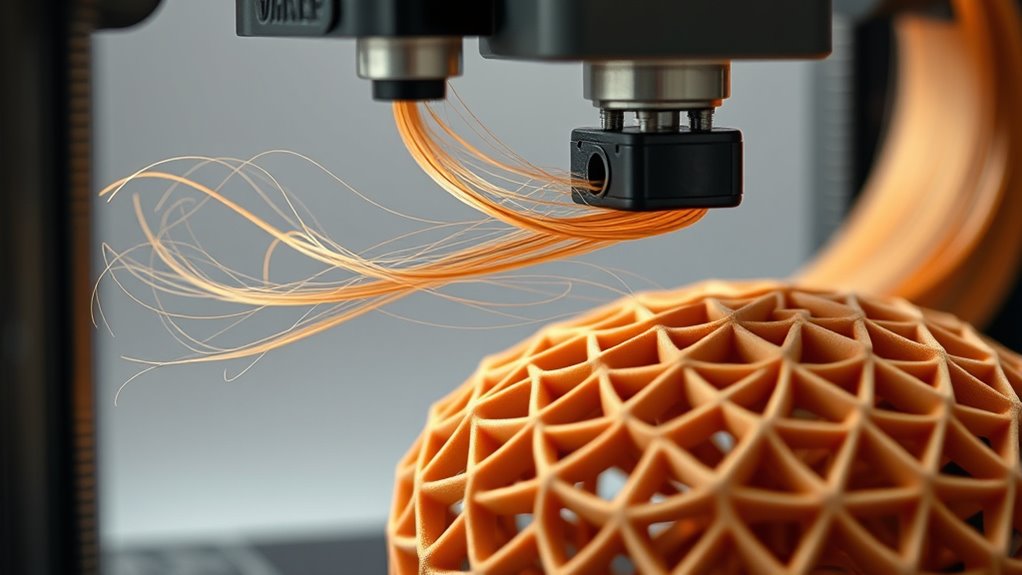

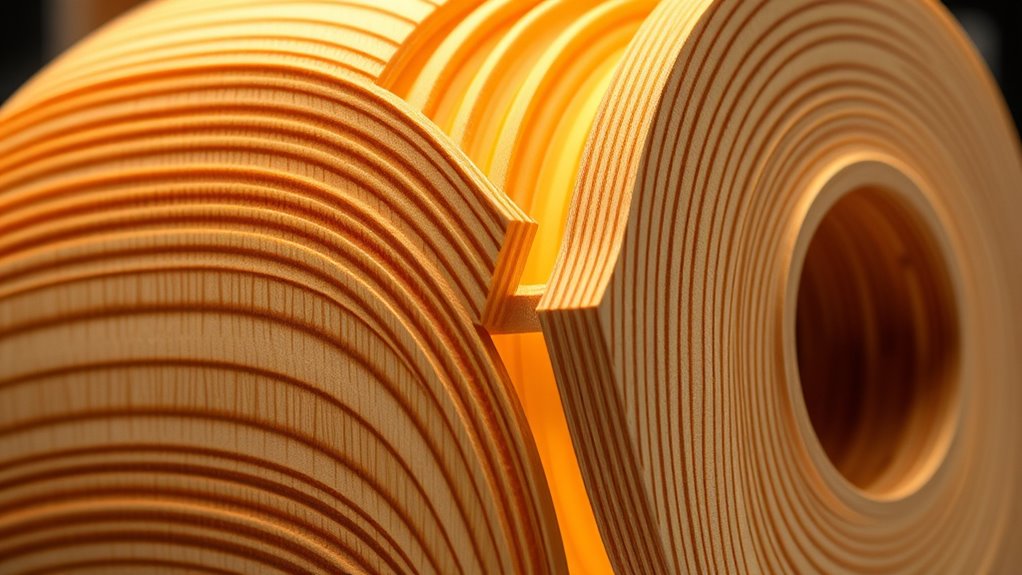

Wood 3D printing employs several distinct methods, each suited for different applications and material properties. Filament extrusion involves mixing wood fibers—usually 30-40%—with polymer binders to create wood-filled filaments, ideal for decorative and hobbyist projects. Powder bed technologies, like binder jetting, use fine wood dust and binding agents to produce complex, waste-free structures with superior surface quality. Binder jetting, in particular, allows for layer-by-layer additive manufacturing of functional wooden parts, often utilizing recycled wood or waste-derived sawdust as natural materials. These techniques expand the possibilities of wood 3D printing, offering versatility in material choices and structural designs. While filament extrusion provides accessible options, powder bed methods excel in producing detailed, durable, and environmentally friendly wooden objects. Additionally, understanding the color accuracy of the printing process can influence the final aesthetic quality of wooden prints. Furthermore, advancements in material compatibility are paving the way for more diverse and innovative applications in the industry, supported by ongoing research into essential oil properties for enhancing material performance. A new sentence with environmentally friendly materials and the rest of the sentence.

Material Innovations and Their Mechanical Performance

Advancements in material formulations have markedly impacted the mechanical performance of wood-based 3D printed objects. Incorporating wood fibers into bio-based composites enhances mechanical properties, but results vary depending on binder formulations. For instance, polymer binders like wood glue produce composites with higher yield strength and elastic modulus—around 0.9–1.05 GPa—offering better structural integrity. Conversely, formulations using acetone tend to be brittle, with poor homogeneity and limited mechanical performance. DMSO-based composites often remain gel-like, preventing full hardening. Overall, bio-based wood composites achieve mechanical properties comparable to rigid polymer foams, with elastic moduli between 0.1–1 GPa and yield strengths from 1 to 10 MPa. These innovations demonstrate promising material performance potential for additive manufacturing, despite existing limitations. Additionally, ongoing research into fiber-matrix adhesion aims to further enhance mechanical stability and durability of these composites. Furthermore, exploring material compatibility can lead to improved integration of wood fibers with various binders, unlocking new possibilities for complex geometries and stronger structures. Continuing advancements in composite formulation are essential for overcoming current challenges and expanding the applications of wood-based 3D printing.

Environmental Benefits and Sustainability Challenges

Additive manufacturing with wood-based materials offers significant environmental benefits by promoting recycling and reducing waste. Using recycled wood helps address deforestation, conserving natural resources and supporting a circular economy. Incorporating bio-based binders like methylcellulose minimizes environmental hazards compared to solvent-based adhesives, improving the overall environmental impact. This manufacturing process enables waste reduction through layer-by-layer fabrication and waste-free techniques like binder jetting. While biodegradable filaments such as PLA-based wood composites provide eco-friendly options, scaling their production and ensuring environmental safety remain challenges. The use of wood stove decor in sustainable design highlights the importance of integrating eco-friendly materials into everyday applications. These advancements highlight the potential for sustainable 3D printing, but careful consideration is needed to balance eco-friendly materials with manufacturing efficiency and environmental safety, making wood-based additive manufacturing a promising yet complex approach to sustainability. Additionally, implementing fire safety standards during production and application can help mitigate potential hazards associated with new materials and processes. Furthermore, ongoing research into bio-based binders aims to enhance the durability and environmental compatibility of these materials, fostering broader adoption in the industry.

Practical Applications and Potential Uses in Construction

3D printing with wood-based materials opens new possibilities for sustainable construction by allowing the creation of decorative and non-structural components that resemble natural wood in appearance and texture. You can use biomaterials like lignin and methylcellulose as binders, enabling environmentally friendly, recyclable architectural components. This technology supports innovative jointing techniques, helping to assemble complex designs with precision. While current limitations, such as water sensitivity and limited load-bearing capacity, restrict large-scale structural applications, 3D printing excels in producing intricate decorative fixtures and custom elements. Powder bed binder jetting, for example, creates waste-free, high-quality wooden parts from recycled sawdust. Additionally, the use of natural materials in 3D printing promotes sustainability and aligns with eco-friendly building practices. As research advances, these applications will expand, making 3D printed wood a valuable tool for sustainable, innovative construction projects. Furthermore, ongoing research into biodegradable materials promises to further enhance the environmental friendliness of 3D printed wood components. Moreover, addressing the environmental impacts of wood-based materials is essential for ensuring that 3D printing remains a truly sustainable solution in construction. Advances in AI security can also contribute to optimizing manufacturing processes and safeguarding intellectual property in this emerging field. Developing innovative fabrication techniques will further improve the precision and versatility of 3D printed wood components.

Overcoming Current Limitations and Future Outlook

Despite promising developments, current wood 3D printing techniques still face significant challenges that limit their broader use. Issues like brittleness, porosity, and low-temperature resistance hinder load-bearing applications. Process limitations, such as lengthy curing times and safety concerns with solvent-based binders like acetone, slow down industrial adoption. However, material innovation offers hope. Researchers are exploring sustainable materials like recycled wood and lab-grown timber to enhance mechanical properties and environmental impact. Additionally, advancements in biocomposite materials could further improve durability and functionality in additive manufacturing. These innovations are essential for achieving holistic healing and expanding the applications of 3D printed wood products. In additive manufacturing, overcoming these barriers involves improving binder jetting methods and developing new composites. The table below highlights key areas for future focus:

| Challenge | Solution | Impact |

|---|---|---|

| Brittleness | Material innovation | Stronger structures |

| Curing time | Faster curing processes | Rapid production |

| Safety risks | Eco-friendly binders | Safer workflows |

| Process limitations | Sustainable materials | Broader applications |

Furthermore, integrating AI-driven process monitoring can optimize printing parameters and improve overall quality.

Frequently Asked Questions

What Are the Pros and Cons of Wood Filament?

You’ll find that wood filament offers a natural, wood-like appearance and texture, making your prints aesthetically pleasing and customizable. However, it’s more brittle and abrasive, so you need hardened nozzles and careful maintenance. It’s also more expensive and slower to print with. While great for decorative pieces, avoid high-stress projects since the material isn’t built for strength or heavy loads.

What Are the Limitations of 4D Printing?

Did you know that only about 10% of smart materials are suitable for 4D printing? You find that the main limitations include material constraints, as few smart materials can reliably change shape or properties over time. Designing and programming these behaviors is complex and costly, and scaling up remains a challenge. Plus, long-term stability of transformations under real-world conditions is still under research, restricting widespread use.

What Are the Limitations of 3D Printing?

You should know that 3D printing faces several limitations. It often struggles with material restrictions, leading to limited strength and durability. Additionally, print resolution and speed can be issues, making large or complex projects time-consuming. You’re also likely to encounter challenges with surface finishes, porosity, and water sensitivity in some materials. Finally, a lack of standardized testing and regulation can complicate quality assurance and large-scale adoption efforts.

Is 3D Printing Wood Possible?

Yes, you can 3D print with wood, using methods like filament extrusion with 30-40% wood fibers or binder jetting with recycled wood dust. These techniques let you create objects that look, feel, and even smell like real wood, making them great for decorative or hobby projects. However, be aware of challenges like brittleness, flammability, and high temperatures that can cause charring instead of melting.

Conclusion

Just as Da Vinci envisioned endless possibilities, wood 3D printing opens new doors in design and construction. While current limitations echo the challenges faced by early innovators, ongoing advancements promise a sustainable future. Embrace these innovations, and you’ll be part of a movement transforming raw ideas into tangible realities—much like turning the forest’s bounty into masterpieces. With persistence and creativity, you’ll help shape a greener, more adaptable world through this groundbreaking technology.