To troubleshoot lathe issues like vibration and tear-out, check your tool condition for wear or damage and replace if needed. Confirm your spindle alignment is accurate with a dial indicator, and verify that workpieces are securely clamped and centered. Adjust feed rates and cutting parameters to prevent overload. Regular maintenance of bearings and machine parts also helps. If you want to learn more about fixing these problems effectively, there’s more to explore below.

Key Takeaways

- Check for tool wear, dull edges, or damage and replace or resharpen tools as needed.

- Verify spindle alignment using a dial indicator to prevent imbalance and vibrations.

- Ensure workpiece is securely clamped and properly centered to avoid off-center cuts and tear-out.

- Adjust cutting parameters, feed rate, and depth to prevent overload and reduce vibrations.

- Regularly maintain and lubricate machine components to ensure smooth operation and minimize issues.

Have you ever faced unexpected problems while working on your lathe? It can be frustrating, especially when you’re in the middle of a project and suddenly notice irregularities like excessive vibration or rough finishes. Many issues stem from simple causes that you can fix with a bit of troubleshooting. One common culprit is cutting tool wear. Over time, your cutting tool dulls, which causes the tool to lose its sharpness and results in poor surface finish, tear-out, or chatter. When you notice these symptoms, it’s a good idea to inspect your tool for signs of wear—chips, dull edges, or deformation. Replacing or reshaping the tool restores proper cutting action and reduces vibrations. But don’t overlook the importance of proper spindle alignment either. If your spindle isn’t aligned correctly, it introduces imbalance and causes vibrations that ripple through the entire machine, affecting cut quality and tool life. Checking spindle alignment involves ensuring the spindle is true and concentric with the workpiece and the tailstock. Use a dial indicator to verify the alignment; if you find deviations, realign the spindle carefully following your lathe’s manual. Misalignments can also lead to uneven wear on your cutting tools, exacerbating issues like tear-out and chatter.

Another factor that contributes to trouble is improper setup or workholding. If your workpiece isn’t securely clamped or if the setup is off-center, vibrations will increase, and the cutting forces won’t be evenly distributed. This can cause tear-out, especially on softer materials or when using a dull tool. Always double-check your workholding devices and ensure the workpiece is firmly secured before starting the cut. Additionally, pay attention to your feed rate and cutting parameters. Cutting too aggressively can overload the tool and cause excessive wear, which in turn leads to poor surface quality and vibration. Slow down if you notice a rough finish or unusual noise, and adjust your feed and depth of cut accordingly. Proper machine maintenance**** also plays a crucial role in preventing these issues, as well-maintained components help maintain optimal alignment and tool condition.

Lastly, maintain your machine regularly. Proper lubrication, cleaning, and inspection of the spindle, bearings, and ways keep everything running smoothly and help prevent issues before they start. Regularly inspecting and maintaining these components ensures that your spindle remains aligned and your tools stay sharp longer. When you combine proper tool maintenance, correct spindle alignment, and careful setup, you’ll considerably reduce unexpected problems, improve your work quality, and extend the life of your lathe. Troubleshooting isn’t just about fixing problems as they come; it’s about understanding what causes them and taking proactive steps to keep your machine operating at peak performance.

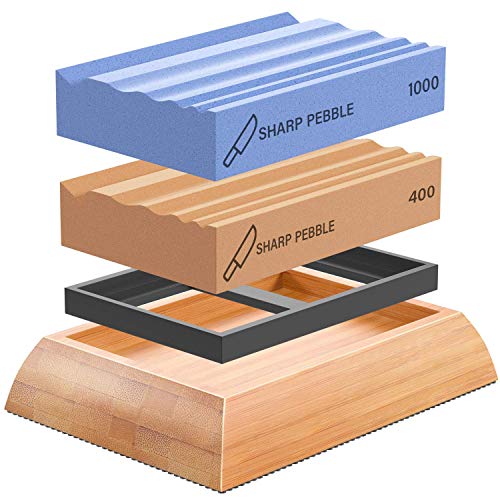

Sharp Pebble Sharpening Stones for Wood Carving Tools-Two Whetstones Grit 400 & 1000 Gouge Sharpener- Waterstone Sharpening System for Wood Carving Knives & Chisels with Non-Slip Bamboo Base

Innovative Sharpening Stones: Our groundbreaking gouge sharpening stone comes with multiple grooves for sharpening Lathe Tools, Wood Carving…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Can I Prevent Lathe Vibration During High-Speed Cuts?

To prevent lathe vibration during high-speed cuts, you should optimize your cutting speed and focus on proper tool selection. Lower the cutting speed if vibrations persist, and choose a tool with the right geometry and sharpness to reduce chatter. Confirm your workpiece is securely clamped and your machine is well-maintained. Properly balancing your setup and adjusting feed rates can also help minimize vibrations for smoother cuts.

What Are the Signs of Worn-Out Lathe Bearings?

You’ll notice bearing wear through increased noise detection, such as grinding or squealing sounds, during operation. Additionally, you might see excess play or movement in the spindle or chuck, indicating worn-out lathe bearings. These signs suggest it’s time to inspect and possibly replace the bearings to prevent further issues. Regular maintenance and monitoring noise levels help catch bearing wear early, ensuring smoother, safer machining.

How Do I Adjust the Lathe’s Spindle Alignment?

A stitch in time saves nine, so start by checking your spindle alignment carefully. First, loosen the headstock or tailstock, then adjust the calibration procedures to align the spindle properly. Use a dial indicator to measure deviations, making small adjustments until the spindle runs true. Tighten everything securely, and recheck the alignment. Proper calibration ensures smooth operation and prevents issues like vibration or tear-out.

What Lubricant Should I Use for Optimal Lathe Performance?

For ideal lathe performance, you should use high-quality spindle oil or light machine oil, depending on your lathe’s specifications. Proper lubricant selection is key to reducing wear and tear. Follow a regular maintenance schedule, applying lubricant at recommended intervals to keep all moving parts running smoothly. Always check your lathe’s manual for specific lubrication recommendations, ensuring you use the right type and amount for long-lasting, efficient operation.

How Often Should I Perform Maintenance on My Lathe?

A stitch in time saves nine, so you should perform maintenance on your lathe regularly. You should do routine inspections weekly, checking for wear and tear. Dust removal is essential—clean the machine to prevent buildup that can cause issues. Lubricate moving parts as needed, and tighten any loose components. Consistent maintenance keeps your lathe running smoothly and prolongs its lifespan, saving you time and money in the long run.

SST – Lathe Tool Post Indicator – High-Level Precision & Accuracy – Durable Construction – 5-Year Warranty Guaranteed

LATHE TOOL POST INDICATOR – Achieve faster, more accurate setups with Stupid Simple Tools’ Lathe Tool Post Indicator,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Remember, troubleshooting your lathe is like tuning a musical instrument—you need patience and a keen ear. I once watched a fellow woodworker fix a wobbling spindle by simply realigning the tailstock, and everything else fell into place. Just like tuning a guitar, small adjustments can make a big difference. Don’t get discouraged by issues; with careful observation and steady hands, you’ll soon be creating smooth, precise cuts every time.

HFS(R) 58 Pieces 5/8" T-Slot Hold Down Clamp Clamping Set Kit for Use with Bridgeport mills (5/8" Slot 1/2"-13 Stud)

[Specification]: Table T-Slot size: 5/8IN;Stud size: 1/2IN-13;packing: T Nut No. TN-0212,Step Clamp:25S-12, 40S-12, 60S-12, (2pcs of Each size),Step…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

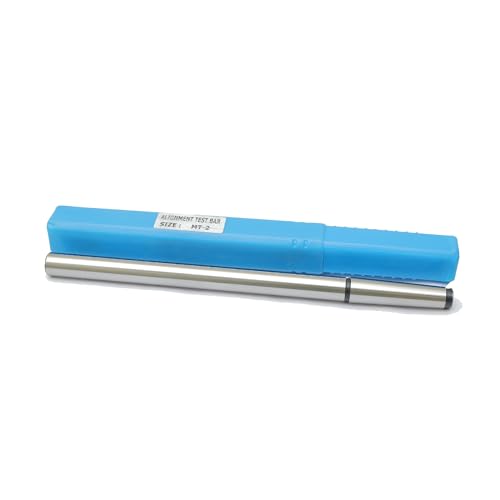

Rahish Tools 2MT Parallel Lathe Alignment Test Bar with High Precision Bar Alloy Steel EN31 Mandrel – Tailstock Re-Alignment Tool with 1 Micron Accuracy & Morse Taper with Max Run-Out of 0.0001"

High-Precision Tailstock Alignment Tool: Achieve perfect alignment with the Rahish Tools Lathe Alignment Test Bar, designed for alloy…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.