If you’re after the best wood edge banding products for a seamless finish in 2025, I’ve got you covered. From natural veneers like walnut, oak, and birch to easy-to-use pre-glued options with heat activation, there’s something for every project. I recommend considering flexibility, surface compatibility, and application tools to get professional results. Want to discover top picks and techniques? Keep exploring to find the perfect match for your needs.

Key Takeaways

- Explore a variety of wood edge banding materials, including natural veneers, pre-glued tapes, and melamine rolls for seamless finishes.

- Consider application methods like heat-activated adhesives, household irons, and trimming tools suitable for DIY and professional use.

- Evaluate product features such as material compatibility, flexibility, finish quality, and durability for different furniture projects.

- Be aware of potential quality issues like seams, color variations, and inconsistent glue coverage that may affect final appearance.

- Choose edge banding options tailored for indoor or outdoor use, matching your furniture style, with options for easy application and long-lasting results.

GSCIT Club Birch Edge Banding, 3 inch x 25ft Roll of Wood Veneer Edge Banding

Are you looking for a reliable edge banding solution that combines natural appearance with easy application? The GSCIT Club Birch Edge Banding offers just that. It’s a 3-inch by 25-foot roll of real wood veneer, pre-glued for quick, hassle-free installation. Made from high-quality, durable birch, it’s flexible and resistant to dirt, making it perfect for furniture repair and DIY projects. The heat-activated adhesive simplifies the process—just iron it on and trim the excess. Customers praise its seamless look and professional finish, though some batches may have minor seams or color variations. Overall, it’s a dependable choice for a natural, polished edge.

Best For: DIY enthusiasts and professionals seeking an easy-to-apply, natural-looking edge banding solution for furniture repair and restoration.

Pros:

- Made of high-quality real wood veneer, durable and flexible

- Pre-glued with heat-activated adhesive for quick, hassle-free installation

- Provides a seamless, professional finish with easy trimming

Cons:

- Some batches may have minor seams or color inconsistencies

- Less effective on curved edges without additional adhesive or tools

- Potential for defective or damaged rolls during shipping, requiring customer support resolution

Edge Supply Walnut Plywood Edge Banding, 3/4” x 50’ Roll

The Edge Supply Walnut Plywood Edge Banding, 3/4” x 50’ Roll, is an excellent choice for DIYers and pros wanting a top-tier, natural wood veneer finish. Made in the USA, it features pre-glued, real walnut veneer that’s finely sanded for smooth edges. It’s versatile, covering exposed edges on plywood, MDF, particle board, and more, adding durability and a polished look. Applying is straightforward—just heat with an iron or hot air blower, then press for a secure, professional bond. Perfect for staining or painting, this roll provides 50 feet of premium veneer, making it ideal for furniture, cabinetry, or craft projects.

Best For: DIY enthusiasts and professional woodworkers seeking a high-quality, natural walnut veneer edging for furniture, cabinetry, and craft projects.

Pros:

- Easy to apply with household tools like an iron or hot air blower, making it accessible for DIYers

- Made from real, high-grade walnut veneer that provides a professional, polished finish

- Durable and versatile, suitable for covering edges on various surfaces like plywood, MDF, and particle board

Cons:

- Slight color discrepancies may occur compared to images, requiring careful selection

- Adhesive residue from labels or tape can impact initial application; proper handling is needed

- Unfinished surface may require staining or painting for a perfect match with other project components

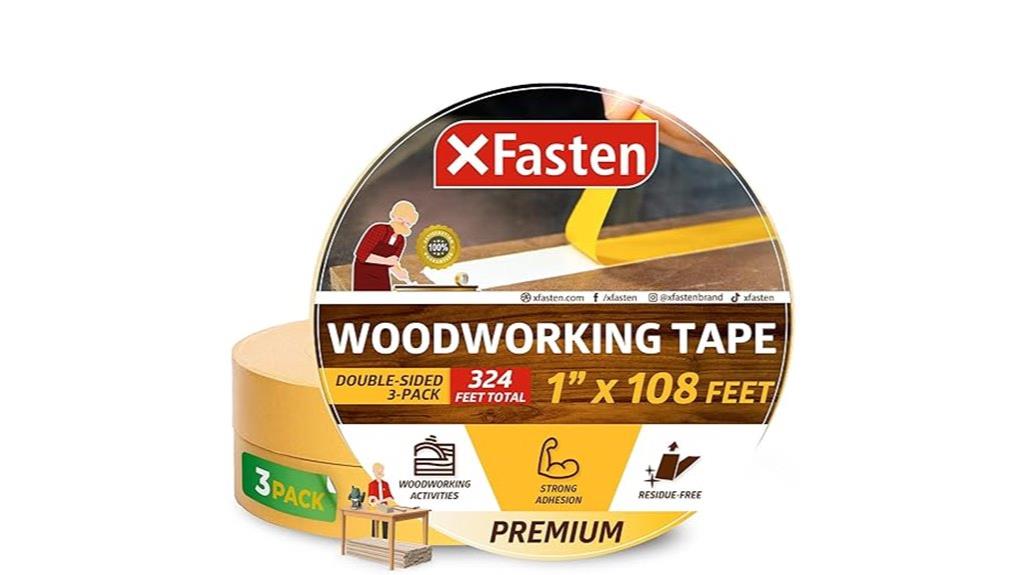

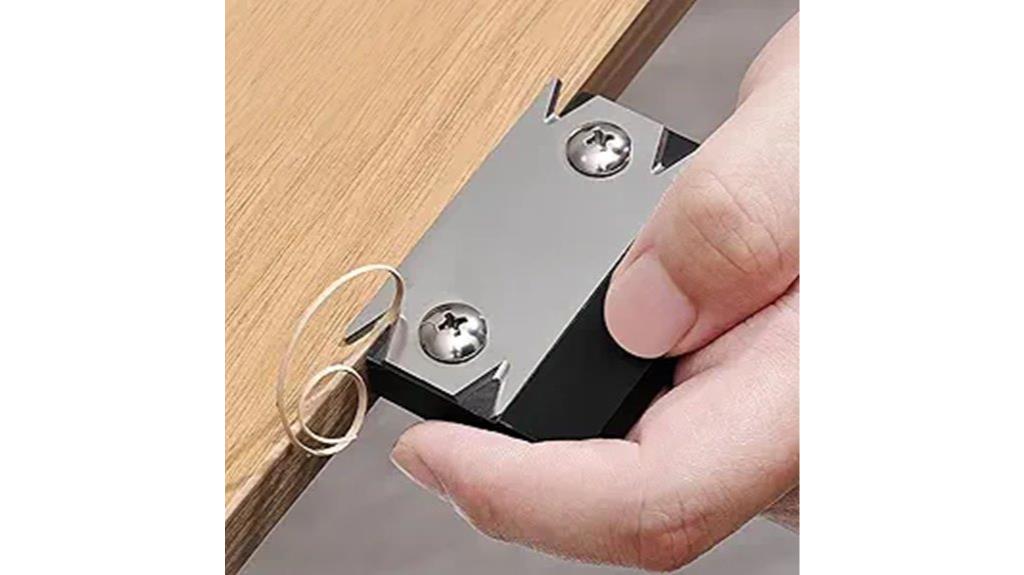

XFasten Double Sided Woodworking Tape (3-Pack)

For professional and serious DIY woodworkers seeking a reliable double-sided tape, XFasten Double Sided Woodworking Tape (3-Pack) stands out thanks to its strong, residue-free adhesion and manageable thickness. Developed with input from professional woodworkers, it features a woven cloth backing that resists curling and a silicone-based adhesive that sticks securely without damaging surfaces. At approximately 0.5mm thick, it’s easy to peel, cut, and remove, making it perfect for edge banding, CNC routing, and temporary fixtures. With 108 feet per roll and a three-pack, it offers great value, durability, and versatility for both complex projects and quick fixes.

Best For: professional woodworkers and serious DIY enthusiasts seeking a reliable, residue-free double-sided tape for woodworking projects like edge banding, CNC routing, and temporary fixtures.

Pros:

- Strong, residue-free adhesion that securely holds workpieces without damaging surfaces

- Woven cloth backing resists curling and enhances manageability during application

- Easy to peel, cut, and remove, making it convenient for quick adjustments and reusability

Cons:

- Thickness of approximately 0.5mm may be too bulky for very fine or precision applications

- Limited to woodworking and related surfaces; may not adhere well to non-porous or very smooth materials

- Slight effort required for removal compared to ultra-thin tapes, which could be a concern for delicate surfaces

Self-Adhesive U Channel Edge Trim for Plywood and Cabinets, 20Ft Black

If you need a durable, easy-to-install edge protection for plywood or cabinet surfaces, the Self-Adhesive U Channel Edge Trim is an excellent choice. Made from soft EPDM rubber, it offers superior oxidation resistance and flexibility, making it perfect for outdoor or sunlit areas. The 20-foot black trim fits 3/4-inch edges and features a self-adhesive backing with three tape strips, ensuring a strong, reliable bond without glue. It’s simple to peel and stick, and can be removed easily without residue, allowing for reuse. With high ratings and positive reviews, it combines durability, ease of use, and versatility for a seamless finish.

Best For: DIY enthusiasts, furniture makers, and homeowners seeking a durable, easy-to-install edge trim solution for plywood, cabinets, and outdoor furniture.

Pros:

- Easy to install with self-adhesive backing and peel-and-stick application.

- Made of flexible, UV-resistant EPDM rubber suitable for outdoor use.

- Reusable and residue-free removal, providing long-term protection and a professional finish.

Cons:

- Limited to edges approximately 3/4 inch thick; not suitable for larger or smaller edges.

- May require precise alignment during installation to ensure a seamless look.

- As a rubber material, it might be less rigid than plastic trims for certain aesthetic preferences.

Edge Supply Birch Wood Veneer Edge Banding Roll

Edge Supply Birch Wood Veneer Edge Banding Roll is an excellent choice for DIY enthusiasts and professionals seeking a natural, high-quality edge finishing solution. Made from high-grade birch veneer, it’s 3/4 inch wide and 50 feet long, perfect for matching 3/4 inch plywood. The pre-glued, iron-on adhesive simplifies installation—just heat with an iron, press, and trim. The real wood veneer can be stained, painted, or sealed to match any project. It offers a durable, professional look and easy handling, making it ideal for furniture, cabinetry, and repairs. Overall, it’s a versatile, reliable option for achieving seamless, attractive edges.

Best For: DIY enthusiasts and professionals looking for an easy-to-apply, high-quality natural veneer edge finishing solution for furniture, cabinetry, and repairs.

Pros:

- Easy to install with pre-glued, iron-on adhesive for quick, secure bonding

- Made from high-grade birch veneer that can be stained, painted, or sealed for a customized finish

- Durable and professionally attractive, suitable for a variety of woodworking projects

Cons:

- Slight overhang may require careful trimming for a perfect edge

- Adhesive re-emergence or seam visibility can occur if not applied properly

- Requires tools like a household iron or edge trimmer for best results

Dovetail Birch Edge Banding Wood Veneer Tape (50Ft, 3/4 Inch)

Looking to achieve a sleek, professional finish on your woodworking projects? The Dovetail Birch Edge Banding Wood Veneer Tape is a fantastic choice. At 50 feet long and 3/4 inch wide, it’s pre-glued for easy application and designed to conform to curves and edges effortlessly. Made from natural, premium-grade birch veneer, it provides a smooth, stainable surface that enhances your project’s aesthetic. Whether you’re finishing cabinets, DIY crafts, or repairs, this veneer tape offers durability and a seamless look. Many users find it straightforward to apply, though some note occasional inconsistencies in glue coverage. Still, it’s a reliable, affordable option for both hobbyists and professionals.

Best For: DIY enthusiasts and professionals seeking an easy-to-apply, natural-looking veneer solution for finishing wood edges and repairs.

Pros:

- Pre-glued for effortless application, saving time and effort

- Conforms easily to curves and edges for a seamless finish

- Made from natural, stainable birch veneer enhancing aesthetic appeal

Cons:

- Inconsistent glue coverage in some batches may require additional adhesive

- Thinner material or varying thickness can affect uniformity and durability

- Occasional quality issues reported by users, impacting long-term adhesion

GSCIT Club Birch Edge Banding, 3/4 inch x 50ft Roll of Veneer for Furniture Repair

The GSCIT Club Birch Edge Banding is an excellent choice for DIY enthusiasts and furniture restorers seeking a high-quality veneer tape. Made from durable, elastic real wood, it features a smooth surface resistant to dirt, perfect for sealing plywood, MDF, or particle board edges. With a 3/4 inch width and 50-foot length, it’s easy to apply using the pre-applied heat melt adhesive and a heated iron. After cooling, excess can be trimmed cleanly. While it adheres well to flat surfaces, curved areas may need additional glue. Customers praise its ease of use and good color match, making it a reliable option for updating furniture.

Best For: DIY furniture restorers and hobbyists seeking a high-quality, easy-to-apply veneer tape for furniture repair and upgrading.

Pros:

- Easy to apply with pre-applied heat melt adhesive and common iron.

- Made from durable, flexible real wood with a smooth, dirt-resistant surface.

- Provides a seamless, natural wood finish that blends well with various furniture types.

Cons:

- Less effective adhesion on curved surfaces without additional glue.

- Some users report minor seams, transparency issues, or material waste.

- Occasional defective rolls due to handling, requiring customer service assistance.

Edge Banding Trimmer, Upgraded Mini Veneer Edge Trimmer for Woodworking

If you’re working on woodworking projects that require precise edge trimming, the upgraded NECAMOCU Mini Veneer Edge Trimmer is an excellent choice. Its stainless steel blades with thicker edges and larger screws guarantee durability and smooth cuts. The lightweight, ergonomic design, weighing just 2 ounces, makes it easy to handle for both straight and curved edges on veneer, PVC, or laminate. The non-slip phenolic base provides stability, while the reversible blades make maintenance simple. Perfect for DIY, cabinetry, or furniture projects, this manual trimmer delivers consistent, clean results and is backed by a lifetime warranty, making it a reliable tool in any workshop.

Best For: DIY enthusiasts, woodworkers, and furnituremakers seeking a precise, lightweight manual edge trimming tool for veneer, PVC, or laminate edging.

Pros:

- Durable stainless steel blades with thicker edges for long-lasting sharpness and smooth cuts

- Lightweight and ergonomic design, weighing only 2 ounces, for comfortable handling during detailed work

- Reversible blades and a non-slip phenolic base for easy maintenance and stable, accurate trimming

Cons:

- Requires manual effort, which may be tiring for large projects or thick materials

- Excessive pressure or improper angle can lead to gouging or damage, especially on hard or sensitive surfaces

- Not suitable for power-assisted or heavy-duty edge trimming tasks

Edge Supply Birch Plywood Edge Banding Roll (3/4 inch x 50 ft)

For those seeking a high-quality, easy-to-apply edge banding solution, the Edge Supply Birch Plywood Edge Banding Roll offers a reliable choice. Made from high-grade, pre-glued natural birch veneer, it’s finely sanded for a smooth finish and can be stained or painted to match your project. The 3/4-inch width and 50-foot length make it versatile for furniture, cabinetry, or DIY crafts. Applying is simple with household tools like an iron or hot air blower, thanks to its strong hot melt adhesive. While joints can be visible if not aligned carefully, overall, it provides a durable, attractive edge at an affordable price.

Best For: DIY enthusiasts, furniture restorers, and cabinetry professionals seeking an affordable, high-quality edge banding solution for flat, square-edged surfaces.

Pros:

- Easy to install with household tools like an iron or hot air blower.

- Made from high-grade, pre-glued natural birch veneer for a smooth, professional finish.

- Offers excellent value with reliable adhesion and durability over time.

Cons:

- Visible joints where short strips are glued together, especially on larger projects.

- Less suitable for rounded or uneven edges, requiring careful handling or additional tools.

- Precise measurement and alignment are necessary, as the 3/4-inch width offers little margin for error.

Edge Supply Birch Wood Veneer Edge Banding Roll (1-1/2″ x 25 ft)

Edge Supply’s Birch Wood Veneer Edge Banding Roll (1-1/2″ x 25 ft) is an excellent choice for DIY enthusiasts and professional woodworkers seeking a high-quality, natural finish. Made from premium birch veneer, it’s pre-glued with a strong German hot melt adhesive for easy application. The flexible veneer can be applied using a household iron or edge banding machine, bonding securely to surfaces like plywood, MDF, or metal. It’s sanded for a smooth look and can be stained or painted to match your project. While some users note minor issues with staining consistency, overall, it offers durability and a polished appearance perfect for furniture and cabinetry.

Best For: DIY enthusiasts and professional woodworkers seeking a high-quality, natural veneer edging solution for furniture, cabinetry, or craft projects.

Pros:

- Easy to apply using household iron or edge banding machine with strong, pre-glued adhesive

- Sanded finish allows for staining or painting to match various surfaces

- Durable and provides a polished, professional appearance

Cons:

- Some users report uneven stain absorption leading to blotchy finishes

- Thin and brittle veneer may split or chip if not handled carefully

- Possible visible splices or segmented pieces rather than a continuous roll in some batches

X246ft Plywood Edge Banding with Hot Melt Adhesive

The X246ft Plywood Edge Banding with Hot Melt Adhesive is an ideal choice for DIY enthusiasts and professionals seeking a durable, easy-to-apply solution for repairing and finishing furniture edges. Made of wood veneer, it measures 4/5 inch wide and comes in a lengthy roll, giving you plenty of material. The high-quality imported hot melt adhesive on the back guarantees a strong, secure bond, while the tacky backing surface simplifies application. Its natural veneer pattern, resembling walnut but darker, provides an attractive, seamless finish. Perfect for plywood, density, and particle boards, it’s versatile and straightforward to use, making your furniture projects look professional with minimal effort.

Best For: DIY enthusiasts and professional woodworkers seeking a durable, easy-to-apply edge banding solution for furniture repair and finishing.

Pros:

- Strong adhesion from high-quality imported hot melt adhesive ensures a durable bond.

- Easy to apply with a tacky backing surface, making it suitable for quick DIY projects.

- Attractive natural veneer pattern enhances the appearance of furniture edges seamlessly.

Cons:

- The veneer color resembles darker walnut, which may not match all furniture styles or stains.

- Not ideal for staining projects; better suited for painting or natural finishes.

- Limited color options; primarily available in a veneer pattern similar to walnut or birch.

Chamfering Machine for Woodworking and Edge Trimming

A chamfering machine stands out as an essential tool for woodworking professionals seeking precise, clean edges after trimming. I find it highly effective for finishing edges on plywood and similar materials, especially after applying edge banding. Its compact, safe design with replaceable blades makes it easy to handle and maintain. The machine performs both trimming and chamfering, saving time and effort on tasks like easing edges of banded surfaces. While not meant for removing large amounts of material, it delivers professional results for detailed finishing. Overall, I recommend it for small, precise edge tasks, as it ensures smooth, accurate edges every time.

Best For: DIY enthusiasts and woodworking professionals seeking precise, finishing touches on edges of plywood and edge-banded surfaces.

Pros:

- Compact and safe design for easy handling and maintenance

- Replaceable blades ensure long-term durability and consistent performance

- Effective for trimming and chamfering edges, saving time on finishing tasks

Cons:

- Not suitable for removing large amounts of material or heavy-duty trimming

- Limited to small, detailed edge finishing rather than bulk material removal

- May require some practice to achieve perfectly smooth edges for beginners

High Quality Melamine Edge Banding (Walnut Color, 13/16 in * 50 ft)

For those seeking a durable and visually appealing solution to finish plywood or particleboard surfaces, high-quality melamine edge banding in walnut color offers an excellent choice. Made from tough, heat-resistant melamine, it’s available in 13/16 inches by 50 feet, with dozens of colors and patterns to match your project. The pre-coated hot melt adhesive makes application quick and easy—just heat, press, cool, and trim. It bonds well even on curved surfaces and maintains its color and heat resistance over time. Customers praise its ease of use, strong adhesion, and professional look, making it a cost-effective option for furniture repairs, cabinetry, and DIY woodworking.

Best For: DIY enthusiasts, furniture makers, and professionals seeking a durable, easy-to-apply edge finishing solution for plywood, particleboard, or laminated surfaces.

Pros:

- Easy to install with pre-coated hot melt adhesive, saving time and effort.

- Strong, heat-resistant bond that maintains its appearance over time.

- Wide variety of colors and patterns to match different projects and styles.

Cons:

- Requires a heating tool such as an iron or hot air gun for proper application.

- Thickness of 0.4mm may be less suitable for highly textured or uneven surfaces.

- Limited to specific widths (13/16 in or 7/8 in), which may not fit all edge finishing needs.

Walnut Wood Veneer Edge Banding 1-1/2 Inch x 50ft Roll

If you’re looking to achieve a professional, seamless finish on your furniture or cabinetry projects, walnut wood veneer edge banding is an excellent choice. This high-quality veneer measures 1-1/2 inches by 50 feet with a 0.8 mm thickness, made from solid wood for durability and beauty. It features a smooth surface resistant to dirt and offers good bonding performance. The pre-glued backing makes application straightforward: heat with an iron or heat gun, press, and trim excess edges. Ideal for sealing exposed sides on various surfaces, it enhances aesthetics while protecting furniture, giving you a polished, long-lasting result.

Best For: DIY enthusiasts, furniture makers, and professional carpenters seeking a durable, attractive edge finishing solution for cabinetry and furniture projects.

Pros:

- Easy to apply with pre-glued backing, heat, and press

- Provides a smooth, attractive walnut grain finish resistant to dirt

- Enhances furniture durability and aesthetic appeal with moisture resistance

Cons:

- The pre-glued adhesive may be sparse or uneven in some areas

- Limited roll size may require multiple purchases for larger projects

- Reheating is necessary for repositioning, which may be inconvenient for some users

Birch Edge Banding, 3/4 inch x 50ft roll of Veneer Edge Banding

Birch Edge Banding, 3/4 inch x 50ft roll, is an excellent choice for DIY enthusiasts and professional woodworkers seeking a durable, natural-looking veneer solution. Made from high-quality real wood, it features a smooth surface, resistant to dirt, and a thickness of just 0.6mm, making it easy to handle, cut, and sand. The pre-glued, heat-activated adhesive simplifies installation—just run a heated iron over it, let it cool, then trim excess. Perfect for sealing plywood, particle board, or MDF edges, it offers a seamless, attractive finish for furniture, cabinets, or DIY projects. Many users appreciate its color match and ease of use, despite occasional adhesive concerns.

Best For: DIY enthusiasts and professional woodworkers seeking a durable, easy-to-apply veneer edge banding solution for furniture, cabinets, and craft projects.

Pros:

- Made from high-quality real wood with a smooth, natural appearance

- Pre-glued and heat-activated for quick, effortless installation

- Easy to cut, sand, and trim for a seamless finish

Cons:

- Occasional issues with adhesive quality, such as peeling or air bubbles

- Requires a heated iron for proper application, which may need careful handling

- Limited information on application instructions and potential edge lifting if not applied correctly

Factors to Consider When Choosing Wood Edge Banding

When choosing wood edge banding, I focus on material quality and durability to guarantee it lasts. I also consider how well it matches my surface and its ease of application. Finally, I check the adhesive type and strength to ensure a secure, long-lasting bond.

Material Quality and Durability

Choosing the right wood edge banding hinges on its material quality and durability, which directly affect its appearance and longevity. High-quality options are usually made from real wood veneer like birch, walnut, or oak, giving an authentic look and feel. Durability depends on the thickness and type of adhesive used; thicker materials combined with strong, heat-activated glues resist wear and peeling better. Resistance to dirt, moisture, and temperature fluctuations is vital for lasting performance, especially in humid or variable environments. A finely sanded, smooth finish indicates higher quality, making application easier and results more seamless. Ultimately, the material’s ability to withstand handling during installation and maintain adhesion over time ensures a professional, durable finish that stands the test of time.

Compatibility With Surfaces

Selecting the right wood edge banding requires confirming it’s compatible with your surface type, whether that’s plywood, MDF, particleboard, or metal. Proper adhesion depends on matching the material and its surface texture, so check if the adhesive backing—pre-glued or glue-required—fits your installation method. Consider the banding’s flexibility to contour smoothly around curves or irregular surfaces for a seamless look. Also, verify that the thickness aligns with your surface to prevent gaps or uneven edges. Finally, confirm that the finish—stained, painted, or lacquered—is compatible with the banding material to achieve both a secure bond and an attractive appearance. Taking these factors into account helps you select an edge banding product that adheres well and looks flawless.

Application Method Ease

Opting for an edge banding product with an easy application method can save time and reduce frustration, especially for DIY enthusiasts. Pre-glued options that activate with heat, like a household iron, make installation straightforward, often requiring only a few minutes of heat and pressure to bond securely. Tools such as utility knives, trimming blades, or sanders help clean up excess material and finish edges smoothly. Flexible edge banding that contours to curves may need extra gluing or specialized techniques to ensure proper adhesion. Clear instructions and minimal steps simplify the process, making it accessible even for beginners. Overall, selecting an edge banding with a user-friendly application method ensures efficient, clean, and professional-looking results with less effort.

Color and Grain Match

Matching the color and grain pattern of the edge banding to your core material is essential for achieving a seamless, professional look. If the colors or grain directions don’t align, the finished product can appear mismatched and unpolished. Different wood species like oak, walnut, or birch have distinct tones and grain patterns, so choosing a close match is vital. Grain alignment between the banding and face veneer also enhances visual continuity and minimizes visible seams. Keep in mind that batch-to-batch variations can occur, so ordering all your material from the same batch helps maintain uniformity. Additionally, consider how the wood reacts to staining and finishing, as some veneers take stain differently, which can affect the final match and overall aesthetic.

Adhesive Strength and Type

When choosing wood edge banding, the adhesive type plays a crucial role in guaranteeing a strong, durable bond. Pre-glued heat melt adhesives need heat activation with an iron, creating a solid bond ideal for flat surfaces. Contact adhesives are applied manually and bond instantly, offering permanence but requiring careful application to avoid misalignment and curing time. Pressure-sensitive adhesives rely on pressure to bond and are easier to reposition, but they may have lower initial strength. The adhesive strength directly impacts longevity, resistance to peeling, and the ability to withstand wear—especially on curved or high-traffic edges. Understanding these differences helps me select the right adhesive to assure my edge banding stays secure and looks seamless over time.

Flexibility for Curves

Choosing the right wood edge banding for curved surfaces depends largely on its flexibility. Flexible options like veneer tape conform better to rounded edges, ensuring a smooth, seamless look. Thinner materials, around 0.3mm to 0.6mm, are more adaptable for curves than thicker bandings. Pre-glued edge bandings with heat-activated adhesive make shaping easier when heated evenly with an iron or heat gun. The material’s elastic modulus influences flexibility—real wood veneer generally bends more easily than rigid plastics or melamine. Proper application techniques, such as gradual heating and gentle pressing, help the banding follow complex curves without cracks or lifting. Overall, selecting a flexible, thin, and heat-activated product ensures a clean, professional finish on curved surfaces.

Price and Value

The cost of wood edge banding depends on factors like material quality, width, length, and adhesive type, which all influence the overall value. Thicker and longer rolls usually offer better cost-per-foot, making them more economical over time. High-quality real wood veneer tends to be pricier but delivers a durable, professional look that lasts. It’s crucial to balance price with ease of application—cheaper options might require extra tools or adhesives, increasing overall costs. Comparing prices per foot across different brands and types helps guarantee you’re getting the best deal for your project. While investing in quality may seem costly upfront, it often saves money in the long run by reducing rework and providing a superior finish. Ultimately, choosing the right edge banding depends on your specific needs and budget.

Frequently Asked Questions

How Does Edge Banding Impact Furniture Durability Over Time?

Edge banding plays a vital role in furniture durability because it protects the raw edges from moisture, chips, and daily wear. I’ve noticed that well-applied edge banding prevents water damage and peeling, extending the piece’s lifespan. Over time, quality edge banding resists cracking and warping, maintaining the furniture’s appearance and integrity. So, investing in good edge banding definitely helps my furniture stay sturdy and looking great longer.

Can Edge Banding Be Applied on Curved or Irregular Surfaces?

Absolutely, edge banding can be applied to curved or irregular surfaces. I’ve done it myself using flexible edge banding materials like thermoplastic or PVC, which bend easily without cracking. For tight curves, I carefully heat and mold the banding to fit, ensuring a seamless look. It takes patience, but with the right tools and techniques, you can achieve a professional finish even on challenging surfaces.

What Are Eco-Friendly Options in Wood Edge Banding Products?

Think of eco-friendly edge banding as a green thread woven into our furniture’s fabric. I choose products made from recycled materials, natural adhesives, or biodegradable options. These not only reduce environmental impact but also guarantee safety and sustainability. I recommend looking for certifications like FSC or E0/E1, which assure low formaldehyde emissions. By choosing eco-friendly banding, I feel good about creating beautiful, sustainable pieces that honor our planet.

How Does Temperature Affect the Adhesion of Various Edge Banding Types?

Temperature plays a big role in how well different edge banding types stick. I’ve noticed that higher temperatures can make adhesive flow better, resulting in a stronger bond, while cold weather can cause adhesives to become too stiff or not activate properly. I always guarantee the environment is suitable for the specific edge banding material I’m using, typically around room temperature, to get the best adhesion and a seamless finish.

Are There Specific Tools Recommended for Professional Edge Banding Installation?

Ever wondered what tools make professional edge banding seamless? I recommend a dedicated edge band trimmer, a hot air blower, and a precision iron. These tools help attain a clean, flawless finish. Do you want your project to look like it was done by a pro? Using the right equipment guarantees perfect adhesion and smooth edges, saving you time and frustration. Trust me, quality tools make all the difference.

Conclusion

Choosing the right wood edge banding feels like selecting the perfect finishing touch for a masterpiece—it’s the detail that transforms a good project into a stunning one. I once thought a simple roll would do, but after discovering the variety and quality options out there, I realized it’s like choosing the right frame for a painting. When you pick the best match, your work truly stands out—just like a well-fitted edge that completes the picture.