If you’re after the best methods and tools for perfect wood curves, I recommend exploring steam bending kits, portable steam generators, and flexible steel templates for transferring intricate patterns. You can also consider heat bending with electric plank benders, lamination techniques, and quality router bits for detailed shaping. Safety and precision are key, so investing in reliable, durable tools makes a difference. Stay with me to discover all the essential techniques for flawless curves in your projects.

Key Takeaways

- Use steam bending with steam boxes or generators to relax wood fibers for smooth, natural curves.

- Employ laminating techniques by gluing thin layers onto molds for complex, durable shapes.

- Utilize electric plank benders and heated tools for precise heat bending without moisture.

- Select flexible, high-quality woods like basswood, and pre-soak to increase pliability and reduce cracking.

- Incorporate pattern transfer tools such as steel flexible curves for accurate, intricate curve shaping.

Steam Bending Wood Kit with Steam Box, Hinges, Latch & Generator

If you’re looking for an efficient way to bend wood safely and accurately, the Steam Bending Wood Kit with Steam Box, Hinges, Latch, and Generator is an excellent choice. It includes all the hardware, fittings, and a detailed build plan to create a custom steam chamber. The 1.3-gallon steam generator heats up quickly, providing reliable steam for up to two hours, making it perfect for continuous projects. The kit’s design guarantees uniform steam distribution and secure door operation. Compact and easy to use, it’s ideal for both professionals and hobbyists aiming for smooth, organic curves in their woodworking projects.

Best For: Hobbyists and professional woodworkers seeking an efficient, safe, and customizable steam bending solution for creating smooth, organic curves in woodworking projects.

Pros:

- Includes comprehensive hardware, fittings, and a detailed build plan for easy assembly.

- Features a powerful 1.3-gallon steam generator that heats quickly and provides reliable steam for up to two hours.

- Compact and lightweight design with safety features, making it suitable for both beginners and experienced users.

Cons:

- Hose connectors may be fragile and require careful handling.

- The overall weight of the assembled steam chamber can be heavy, potentially requiring sturdy support.

- Limited customer reviews suggest variability in durability over long-term use.

Earlex SS77USSG Steam Generator, 1.3-Gallon Capacity, 12 Hose, Portable Steam Bender

The Earlex SS77USSG Steam Generator stands out as an excellent choice for hobbyists and small workshop enthusiasts seeking reliable, portable steam for wood bending projects. With a 1.3-gallon water capacity, it provides up to two hours of continuous steam, heating quickly in about 23 minutes. Its 12-foot hose makes it easy to maneuver, and the lightweight design (around 4 pounds) guarantees portability. The unit includes a steam box connector kit and safety features like thermal protection and pressure relief. Perfect for woodworking, steaming, or sauna use, it offers a versatile, effective steam source, making your bending projects smoother and more manageable.

Best For: hobbyists and small workshop enthusiasts seeking a portable, reliable steam source for wood bending, steaming, and sauna applications.

Pros:

- Quick heat-up time of approximately 23 minutes for efficient use

- Large 1.3-gallon capacity provides up to 2 hours of continuous steam

- Lightweight and portable with a 12-foot hose for easy maneuverability

Cons:

- Plastic components may be fragile and prone to breaking if handled roughly or after falls

- Some users report durability issues over extended use or with accidental drops

- Missing accessories like adapters have been noted in some reviews, requiring additional purchases

Steel Flexible Curve Template for Transferring Curved Patterns

The Steel Flexible Curve Template stands out as an essential tool for anyone needing precise transfer of complex, curved patterns. Made of solid steel, it’s durable and built for long-term use, weighing just over a pound. Its adjustable knobs let you lock in the shape, ensuring accurate duplication of both simple and compound curves. I’ve used it across woodworking, metalworking, and upholstery projects, as it easily molds to various shapes. Its versatility makes pattern transferring quick and reliable, saving time and effort. Whether working on furniture, auto parts, or architectural details, I find this tool indispensable for achieving perfect curves with confidence.

Best For: DIY enthusiasts, woodworkers, metalworkers, and professionals seeking precise and versatile curved pattern transfer tools.

Pros:

- Durable solid steel construction ensures long-lasting use and stability.

- Adjustable knobs allow for precise locking of complex and simple curves.

- Versatile application across wood, metal, plastic, leather, and fabric projects.

Cons:

- May require two people to operate effectively when working off the floor or holding the tool steady.

- Slight response lag due to steel flexibility can affect ultra-precise applications.

- Relatively heavy weight (1.1 pounds) might be cumbersome for extended handheld use.

Woodworking Guide to Bending Wood

Woodworking Guide to Bending Wood stands out as an ideal resource for both beginners and experienced woodworkers who want to master various bending techniques. It covers essential methods like green wood bending, laminates, hot water, steam, heat bending, vacuum press, and free-hand guitar side shaping. The guide explains the physics behind wood behavior, grain properties, and when to use each technique. With detailed step-by-step instructions, photos, and illustrations, it helps readers understand advantages and pitfalls. Whether you’re tackling a project or expanding your skills, this book provides practical insights, tools, and tips to achieve perfect curves safely and efficiently.

Best For: hobbyists, students, and professional woodworkers seeking comprehensive guidance on bending techniques and practical projects.

Pros:

- Thorough coverage of multiple wood bending methods with clear instructions and visuals

- Practical tips for equipment, form construction, and troubleshooting failures

- Suitable for all skill levels, from beginners to experienced craftsmen

Cons:

- May require additional resources or equipment for specialized techniques

- Some advanced methods might need further study or practice to master fully

- Focuses primarily on manual techniques, less emphasis on power tools or automation

The Complete Manual of Wood Bending: Milled, Laminated, and Steambent Work

If you’re an intermediate woodworker seeking practical, detailed guidance on bending techniques, “The Complete Manual of Wood Bending” by Schleining is an excellent resource. It thoroughly covers milling, laminating, and steam bending, emphasizing combining methods for ideal results. The manual offers step-by-step instructions, jig plans, safety tips, and troubleshooting advice, making complex techniques accessible. While it doesn’t include specific project plans or forms, the focus on practical knowledge helps you choose the right approach for your project. I find it especially useful for understanding the nuances of each method and how to safely achieve beautiful, precise curves in your woodwork.

Best For: intermediate woodworkers seeking comprehensive, practical guidance on bending techniques, including milling, laminating, and steam bending.

Pros:

- Offers detailed, step-by-step instructions and safety tips for various bending methods.

- Includes jig plans and troubleshooting advice to facilitate successful projects.

- Focuses on combining techniques for optimal results, making complex processes accessible.

Cons:

- Does not provide specific project plans or bending forms for hands-on applications.

- Lacks visual aids such as color photographs or instructional videos, which could enhance understanding.

- Primarily suited for intermediate to advanced users, potentially overwhelming beginners.

Wood Bending Made Simple (Made Simple (Taunton Press))

For beginners or hobbyists enthusiastic to learn wood bending, “Wood Bending Made Simple” offers clear, step-by-step guidance that demystifies complex techniques. Authored by Lon Schleining, it covers steam bending, bent lamination, and heat bending with practical instructions and vivid visuals. The book emphasizes low-tech solutions, form creation, and material preparation, helping you avoid waste and improve results. Its detailed explanations of techniques, tools, and troubleshooting make it accessible for all skill levels. Plus, the included DVD offers visual demonstrations, enhancing understanding. Overall, it’s an invaluable resource for anyone eager to master bending wood and achieve perfect curves with confidence.

Best For: beginners, hobbyists, and experienced woodworkers seeking a clear, practical guide to mastering wood bending techniques with confidence.

Pros:

- Highly visual, step-by-step instructions that simplify complex techniques

- Covers multiple methods like steam bending, bent lamination, and heat bending

- Includes a DVD with visual demonstrations to enhance learning

Cons:

- Limited online resources beyond the book and DVD

- Focuses primarily on low-tech solutions, which may not suit advanced industrial applications

- Some readers may find the level of detail overwhelming if only seeking quick tips

Wood Bending Handbook

The *Wood Bending Handbook* stands out as an essential resource for woodworkers, engineers, and designers seeking practical guidance on bending techniques. This thorough guide, originally from 1948 and reprinted in 1970, offers detailed instructions on hand and machine bending, moisture management, steaming, and adhesives. I appreciate its clear illustrations, data tables, and tips for minimizing risks like cracking. It emphasizes selecting the right wood species and preparing materials correctly. Although some techniques are a bit dated, the book’s focus on practical, tested methods makes it invaluable for artistic projects and structural applications alike. It’s a must-have reference for mastering wood bending.

Best For: woodworkers, engineers, and designers seeking a comprehensive, practical guide to bending wood for artistic and structural projects.

Pros:

- Detailed instructions on both hand and machine bending techniques.

- Clear illustrations, data tables, and practical tips for minimizing risks like cracking.

- Focuses on selecting appropriate wood species and proper preparation for successful bending.

Cons:

- Some techniques and methods are somewhat dated, reflecting older practices.

- The data tables may not account for recent changes in forestry and wood characteristics.

- The book’s content is primarily focused on traditional methods, which may require adaptation for modern equipment or materials.

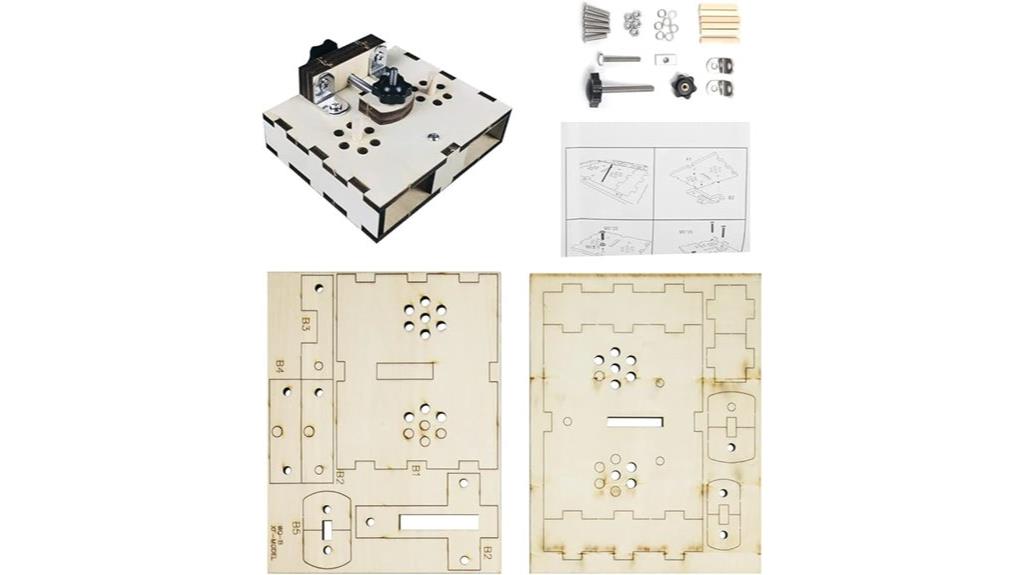

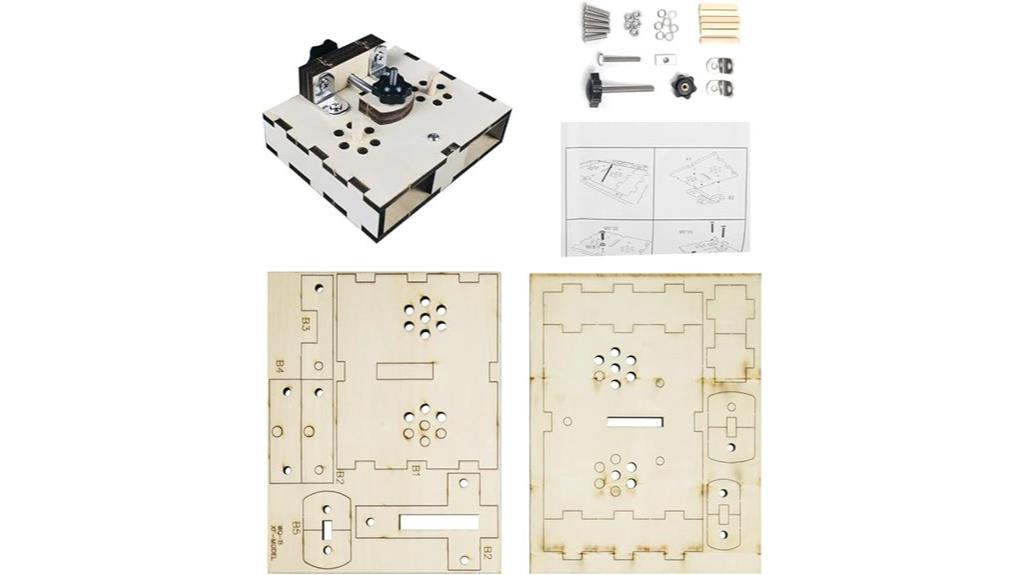

GAWEGM Wooden Ship Model Tools Set

The GAWEGM Wooden Ship Model Tools Set stands out as an ideal choice for hobbyists and model builders focused on creating detailed wooden ship replicas. It includes two wooden plates, instructions, and accessories like a wood strip bending tool and a manual machine, perfect for shaping and assembling ship components. Made from durable basswood laminate, stainless steel fittings, and galvanized nuts, the set is designed for long-term reuse. Its compact size (120mm x 110mm x 60mm) and lightweight build make it easy to handle. This kit requires self-assembly and preparation, such as soaking strips, ensuring precise bending and shaping for your ship model projects.

Best For: hobbyists and model builders seeking a durable, reusable set of tools for detailed wooden ship model crafting.

Pros:

- Made from high-quality, durable materials including basswood laminate, stainless steel fittings, and galvanized nuts.

- Compact and lightweight design for easy handling and storage.

- Includes essential tools such as a wood strip bending tool and instructions, suitable for precise shaping and assembly.

Cons:

- Self-assembly required before use, which may be challenging for beginners.

- No included glue or knives, requiring additional purchases for complete kit assembly.

- Limited to wooden ship model projects, not versatile for other types of modeling.

Yinfente Guitar Side Rib Bending Iron

If you’re looking for an affordable and effective tool for bending guitar sides and violin ribs, the Yinfente Guitar Side Rib Bending Iron stands out. It features a 12cm aluminum body with stainless steel strings, adjustable temperature control, and a heating element with curved surfaces for precise bending. Weighing just over 3.6 pounds, it heats quickly and maintains consistent heat around 190°C at 220°C settings. Users find it works well with various woods like mahogany and rosewood, though tight bends may need extra effort. Just remember to use ventilation due to fumes, secure the unit during use, and handle it carefully to avoid overheating.

Best For: luthiers, guitar builders, and instrument enthusiasts seeking an affordable, effective tool for bending guitar sides and violin ribs with precise temperature control.

Pros:

- Affordable alternative to high-end luthier tools with effective performance

- Quick heating with stable temperature around 190°C at 220°C setting

- Suitable for bending various woods like mahogany, rosewood, and ebony

Cons:

- Lacks mounting holes or clamps, requiring improvisation for stability

- Potential safety hazards due to high temperatures and fumes if not ventilated properly

- Limited size may restrict use for larger instruments or more complex bends

Wood Benders Handbook

For woodworkers enthusiastic to master bending techniques without investing in expensive machinery, the “Wood Benders Handbook” offers practical, step-by-step guidance. It covers essential methods like cold bending, steam, hot air, and kerf cutting, providing clear instructions and useful charts on wood properties. The book also shows how to build equipment such as steam boxes, jigs, and clamps, making DIY projects accessible. Focused on species selection and project plans like boat ribs or chair backs, it inspires confidence. Although it doesn’t explore deeply into milling, its concise advice makes it a valuable resource for both beginners and seasoned woodworkers eager to create perfect curves.

Best For: hobbyist and professional woodworkers seeking practical, no-fuss guidance on bending wood for furniture, instruments, or boats without investing in expensive equipment.

Pros:

- Clear, step-by-step instructions with helpful charts and illustrations.

- Focuses on DIY techniques and building your own equipment like steam boxes and jigs.

- Suitable for all experience levels, from beginners to seasoned woodworkers.

Cons:

- Limited coverage on milling, shaping, and detailed project planning.

- Superficial exploration of some topics, requiring additional resources for in-depth knowledge.

- Packaging issues like creases may occur during shipping, affecting presentation.

Mini Universal Rod Bender for up to 5/16″ (8mm) Steel Rod

A compact and easy-to-use tool like the Mini Universal Rod Bender is perfect for hobbyists and DIY enthusiasts working on small metal projects. It can bend steel rods up to 5/16 inch (8mm) in diameter, making it ideal for creating hooks, hangers, or curved pieces. The bender mounts easily in a bench vise and features a straightforward design with prongs and holes for secure attachment. Its lightweight construction (around 2.92 pounds) allows for quick, repeatable bends, including 180°. While simple, it’s a practical, affordable option for light-duty tasks, especially when working on small-scale metalworking projects.

Best For: hobbyists, DIY enthusiasts, and light metalworkers needing an affordable, portable tool for small-scale bending projects.

Pros:

- Easy to mount in a bench vise or work table for stable operation

- Lightweight and portable at approximately 2.92 pounds

- Capable of making quick, repeatable bends up to 180° or more

Cons:

- Suitable only for bending up to 5/16 inch (8mm) steel rods, limiting versatility

- Basic construction with rough edges typical of low-cost tools

- May require modifications or reinforcement for enhanced durability and precision

Thiecoc Basswood Blocks for Carving (8 Pcs, 4x2x2 Inch)

The Thiecoc Basswood Blocks for Carving are an excellent choice for hobbyists and artisans seeking reliable, high-quality material for detailed woodcraft projects. This set includes eight blocks, each measuring 4x2x2 inches, providing plenty of material for various creations. Basswood’s soft, smooth surface makes it ideal for carving, whether you’re a beginner or experienced. It’s free from splits or cracks, ensuring a clean workspace. The wood’s versatility allows for natural finishes, painting, or staining. Users appreciate its ease of use, although some note initial hardness may require sharper tools or a gentle approach. Overall, this set offers excellent value and quality for creative projects.

Best For: hobbyists, artisans, and woodcraft enthusiasts of all skill levels seeking high-quality, versatile carving material.

Pros:

- Made from soft, smooth basswood ideal for detailed carving and finishing

- Includes multiple blocks providing ample material for various projects

- Free from splits, cracks, or imperfections, ensuring a clean carving surface

Cons:

- Initial hardness may require sharper tools or softening techniques for easier carving

- Slight variations in wood hardness depending on age and moisture content

- Some users may find the size of the blocks limiting for larger projects

GAWEGM Wooden Ship Model Tools Set

If you’re passionate about building detailed wooden ship models, the GAWEGM Wooden Ship Model Tools Set stands out as an essential kit. It includes two wooden plates, instructions, and accessories specifically for model ship construction. The set features a wood strip bending tool and manual machine designed to shape and bend wooden strips easily. Made from durable basswood laminate, stainless steel fittings, and galvanized nuts, it’s built for long-term reuse. With a compact size of about 120mm x 110mm x 60mm and a weight of just 3.52 ounces, this tool set is perfect for hobbyists aiming for precise, professional curves in their ship models.

Best For: hobbyists and model ship builders seeking durable, reusable tools to craft detailed wooden ship models with precision.

Pros:

- Made from durable basswood laminate, stainless steel fittings, and galvanized nuts for long-term reuse.

- Compact size (120mm x 110mm x 60mm) and lightweight (3.52 ounces) for easy handling and storage.

- Includes comprehensive instructions and accessories tailored for precise shaping and bending of wooden strips.

Cons:

- Tools require self-assembly and do not include glue or knives, which may require additional purchases.

- Bending wooden strips necessitates soaking in water, which adds an extra step to the process.

- Limited to model ship construction; may not be suitable for other woodworking projects.

R18 1/2-Inch Shank Woodworking Router Bit

For woodworkers aiming to achieve precise curved bends in laminated materials, the R18 1/2-Inch Shank Woodworking Router Bit stands out as an essential tool. Made from premium-grade alloy, it offers durability and consistent performance, compatible with most 1/2-inch collet routers. Designed to bend laminated materials to a 90-degree angle with a radius of about 3/4 inch, it’s perfect for furniture and architectural projects. While it works best with formable laminates and adhesives, it’s less effective on plywood or MDF without a surface to bend. This bit ensures smooth, professional curves, making it a valuable addition for both novice and experienced woodworkers.

Best For: woodworkers seeking precise, professional-quality curved bends in laminated materials for furniture, architectural, or artistic projects.

Pros:

- Made from durable, premium-grade alloy ensuring long-lasting performance

- Compatible with most 1/2-inch collet routers for versatile use

- Facilitates smooth, accurate curves with minimal effort

Cons:

- Less effective on plywood, MDF, or particle board without a suitable surface to bend

- Cannot be used for incremental cuts or variable-depth shaping

- Requires high-power routers or milling machines, limiting use with standard trim routers

Electric Plank Bender for Hobby Model Ships by Model Shipways – MS7205

Model ship builders seeking consistent, precise bends in wooden planks will find the Electric Plank Bender MS7205 an invaluable tool. This device makes bending strips with accurate curvature straightforward. You place the plank on a wooden form, heat it with the soldering iron handle, and shape it to match the included curves. Soaking the wood beforehand and pinning it helps maintain the desired shape. The kit includes a soldering iron, a metal head, and a wooden form, making it suitable for projects like the USS Constitution. Although some users note minor design flaws, overall, it delivers reliable, consistent bends essential for high-quality model ship building.

Best For: hobbyist model ship builders seeking precise and consistent wooden plank bending for their detailed ship models.

Pros:

- Facilitates accurate, uniform bends in wooden planking strips

- Includes a wooden form and curves for versatile shaping

- Easy to use with effective heating, producing reliable results

Cons:

- Wooden form assembled from multiple pieces may require sanding

- Some users report durability issues with the heating element over time

- Higher price point relative to perceived build quality and manufacturing origin

Factors to Consider When Choosing Wood Bending

When choosing how to bend wood, I consider the material’s compatibility and flexibility to guarantee the process goes smoothly. I also evaluate the appropriate techniques and quality tools needed for my project’s size and complexity. Safety precautions are vital, so I always handle equipment carefully to prevent accidents.

Material Compatibility and Flexibility

Choosing the right wood for bending hinges on understanding its compatibility and flexibility. I always check that the species has high bendability and suitable moisture content to prevent cracking. It’s essential to verify that the grain orientation aligns with the intended bend, as this maximizes flexibility and reduces stress. Sometimes, additional treatments like steaming or soaking are necessary to make the wood pliable enough for shaping. I also consider whether the wood’s thickness and width match the bending method and equipment I plan to use. Finally, I assess the surface and internal properties to guarantee they support the desired curvature without compromising structural integrity. By carefully evaluating these factors, I ensure the wood will bend smoothly and hold its shape effectively.

Bending Techniques and Methods

Have you ever wondered how different bending techniques impact the choice of wood? Each method—steam bending, lamination, heat bending—offers distinct advantages suited to specific projects. Steam bending uses moist heat to relax fibers, ideal for smooth, natural curves in furniture or musical instruments. Laminating involves gluing thin layers onto forms, perfect for complex or repeated shapes with precision. Hot pipe or form-based methods rely on controlled heat without moisture, often used for guitar sides and small parts. When selecting a technique, understanding the wood’s physical properties—grain direction, moisture content, species—is essential. These factors influence how easily and cleanly the wood bends, ensuring the outcome meets your expectations. Matching the right method to your project and material is the key to achieving perfect curves.

Equipment and Tool Quality

The quality of your wood bending tools directly impacts the success of your projects, so it’s crucial to select equipment made from durable materials like alloy, stainless steel, or reinforced plastics. These materials withstand repeated use and help maintain precision over time. Accurate manufacturing standards ensure tools like bending jigs and router bits deliver consistent results. Adjustable components, ergonomic handles, and secure mounting options make tools easier and safer to use. Safety features such as thermal protection, cool-touch hoses, and automatic shut-off reduce the risk of accidents. Investing in high-quality tools minimizes defects, breakage, and inaccuracies, preserving the integrity of your bent wood. In the long run, quality equipment saves you time, effort, and money, making your projects more successful and enjoyable.

Project Size and Scale

When working on wood bending projects, considering the size and scale is essential to selecting the right equipment and techniques. Larger projects need longer or wider steam boxes and more powerful steam generators to guarantee even heat distribution, preventing weak points or uneven bends. The project’s scale also influences the bending method; big furniture components often require laminated or form-based techniques instead of simple steam bending. For smaller projects, portable steam units and compact tools work well, reducing setup time. Additionally, the dimensions of the wood, like thickness and length, directly impact the equipment choice and process. Accurately measuring your project helps determine the right radius and bend angle, ensuring your finished piece fits perfectly within your design specifications.

Safety and Handling Precautions

Ensuring safety and proper handling during wood bending projects is essential to prevent accidents and injuries. Always wear personal protective equipment like gloves, safety glasses, and masks to shield yourself from hot tools, steam, or fumes. Proper ventilation in your workspace helps dissipate harmful fumes from heating elements, adhesives, or burning fibers. Follow safety instructions provided by manufacturers for steam generators and heating devices, paying attention to maximum temperature settings and handling procedures. Regularly inspect and maintain equipment—check hoses for leaks or cracks and verify safety features like pressure relief valves. Handle hot wood, steam, and electrical tools with caution, allowing them to cool before adjustment or cleaning. Staying vigilant reduces risks and keeps your project safe and successful.

Frequently Asked Questions

What Safety Precautions Are Essential During Wood Bending?

When bending wood, safety is essential. I always wear gloves to protect my hands from splinters and hot tools. Eye protection is a must to guard against debris or splashes from steam or glue. I make sure proper ventilation to avoid inhaling fumes, and I keep a fire extinguisher nearby if using heat. Following these precautions helps me work safely and achieve perfect curves without accidents.

How Do Humidity Levels Affect the Bending Process?

Humidity levels play a vital role in the wood bending process. When the air is too dry, wood becomes brittle and prone to cracking, making bending difficult. On the other hand, high humidity keeps the wood moist and flexible, easing the curve formation. I always monitor the environment carefully and adjust humidity levels if needed, ensuring the wood bends smoothly without damage or unwanted cracks.

Can Synthetic or Alternative Materials Be Bent Like Wood?

Thinking about bending synthetic materials is like trying to tame a wild horse—they can be flexible, but it takes the right techniques. I’ve found that certain plastics and composite materials can mimic wood’s curves if heated properly. Just like wood, they need careful handling and the right tools. So yes, many synthetic materials bend well, but knowing their properties is key to avoiding cracks or breakage.

What Are the Signs of Over-Bending or Damaging the Wood?

When I over-bend or damage wood, I notice cracks or splinters forming along the bend. The wood might also feel unusually soft or weak at the curve, indicating stress. Sometimes, I see the surface develop tiny fractures or even peeling layers. If the wood feels overly flexible or starts to snap unexpectedly, I know I’ve pushed it too far. Always pay attention to these signs to prevent permanent damage.

How Long Should Wood Be Held in the Bent Position for Optimal Set?

Think of setting wood like sealing a promise; timing is everything. I usually hold the bend for about 15 to 30 minutes, depending on the wood’s thickness and type. Patience here guarantees the curve holds firmly without over-stressing the fibers. Rushing can cause cracks or springback, so I always test the set before removing clamps. Proper timing guarantees a smooth, lasting curve that truly stands the test of time.

Conclusion

Now that you’ve explored these top wood bending techniques and tools, you’re armed with everything needed to turn raw wood into beautiful, flowing curves. Think of it as guiding a river to carve its perfect path—patience and the right tools make all the difference. Whether steam bending or laminating, I hope your projects bend to your will and turn out just as you envision. Happy crafting, and let your creativity flow like a mighty river!