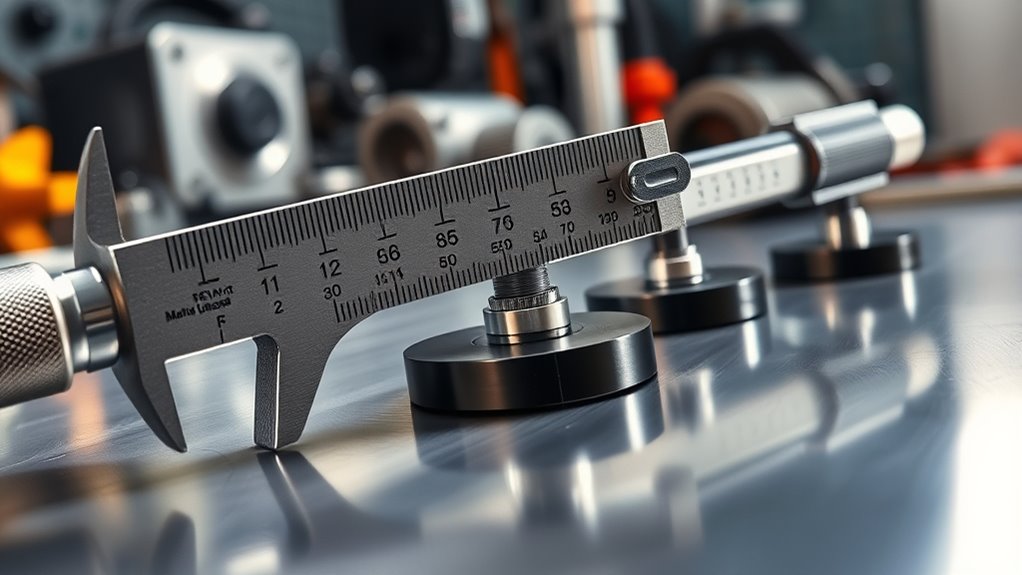

If you’re looking for the 14 best surface gauges with magnetic bases for precise measurements in 2025, I can help you find reliable options. From brands like Shars, Neoteck, and WEN, you’ll get bases with strong magnetic pull, adjustable arms, and durable construction suitable for both hobbyist and professional use. Considering factors like magnetic strength, stability, and compatibility guarantees you select the right tool. Keep exploring, and you’ll discover top choices tailored to your needs.

Key Takeaways

- Top magnetic bases feature strong pull forces (80-175 lbs) for stable, secure mounting on ferrous surfaces up to 30mm thick.

- They offer 360° adjustable arms and flexible joints for precise positioning of dial indicators and surface gauges.

- Durable construction with materials like steel and aluminum ensures long-term reliability and resistance to wear.

- User-friendly models include on/off switches for easy repositioning without losing calibration.

- These bases are suitable for professional and hobbyist use, supporting accurate measurements in various industrial and calibration tasks.

Shars Magnetic Base Holder with Dial Indicator

The Shars Magnetic Base Holder with Dial Indicator is an excellent choice for DIY enthusiasts and hobbyists who need reliable, budget-friendly measurement tools. I appreciate its straight arm design and sturdy steel base, which help keep measurements steady. The set includes a 0.001 graduation dial indicator, providing decent accuracy for general tasks. While the magnetic base offers up to 135 pounds of holding force, some users find it less powerful than premium brands. Be cautious about potential manufacturing flaws, like weak threading or fragile components. Overall, it’s a practical, affordable option for everyday measurement needs, though it may not suit heavy-duty or high-precision applications.

Best For: DIY enthusiasts and hobbyists seeking a reliable, budget-friendly measurement tool for general tasks.

Pros:

- Includes a 0.001 graduation dial indicator for decent accuracy

- Sturdy steel base with straight arm design for stability

- Good value for the price with reliable performance for everyday use

Cons:

- Magnetic base offers less holding strength than premium brands

- Manufacturing flaws such as weak threading and fragile components reported

- Not suitable for heavy-duty or high-precision applications

Shars Uneven-Surface Indicator Magnetic Bases Base Only 202-5997 S]

If you’re working with irregular metal surfaces, the Shars Uneven-Surface Indicator Magnetic Base 202-5997 S stands out because of its strong 80-pound holding force and versatile design. Its universal magnetic base allows for unlimited configurations, making it suitable for various applications, especially on uneven surfaces like rear axles. The cam lock mechanism ensures a secure, stable position, while the on/off switch offers easy control. Customers praise its durability and reliability, noting it lasts for years without failure. Overall, this base provides a dependable, adaptable solution for precise measurements on challenging surfaces.

Best For: professionals and technicians working on irregular metal surfaces, such as rear axles, who need a reliable and versatile magnetic base for precise measurements.

Pros:

- Strong 80-pound holding force ensures stability on uneven surfaces

- Universal magnetic base allows for unlimited configurations and versatility

- Durable construction with years of reliable use, backed by positive customer feedback

Cons:

- May be heavier or bulkier compared to smaller magnetic bases

- Requires a flat, ferrous surface for optimal magnetic grip

- Limited to metal surfaces; not suitable for non-magnetic materials

Neoteck Magnetic Base Stand for Dial Indicator Gauge

For professionals and DIY enthusiasts seeking reliable, versatile mounting solutions, the Neoteck Magnetic Base Stand for Dial Indicator Gauge stands out with its impressive magnetic force and compatibility. It features two solid magnet surfaces with on/off control, offering a maximum tensile force of 176 lbs (80 kg). The stand works best on metal surfaces of at least 1.2 mm thick, ensuring strong adherence. Built with high-quality materials, it’s sturdy and durable, with flexible rotary joints for precise adjustments. Although some users suggest the magnet could be stronger, overall, it provides excellent stability, making it a great value for both hobbyists and professionals.

Best For: professionals and DIY enthusiasts needing a reliable, adjustable magnetic stand for dial indicators and small measurement tools.

Pros:

- Strong magnetic force with a maximum tensile of 176 lbs (80 kg) for secure attachment

- High-quality, sturdy construction with flexible rotary joints for precise adjustments

- Excellent value with competitive pricing and positive user feedback

Cons:

- Plastic knobs may break easily and sometimes require replacement or modification

- Some users feel the magnet strength could be improved for even better adhesion

- The magnetic base is small, which may limit stability in very demanding applications

Dial Indicator with Magnetic Base and Long Arm, 0-1″ Range, Precision Gauge 0.001

A dial indicator with a magnetic base and long arm offers exceptional precision for technicians and hobbyists alike, especially when measurements demand high accuracy within a 0-1 inch range. I appreciate its high resolution of 0.001 inches, which guarantees detailed readings. The fine adjustment knob allows precise positioning, making it ideal for delicate tasks. Its magnetic stand provides stability, while the overall height of nine inches offers flexibility in various setups. With options like flat or lug back options and included test tips, this gauge is versatile. It’s a reliable tool for achieving accurate measurements in machining, calibration, or quality control.

Best For: professionals, technicians, and hobbyists requiring precise measurements within a 0-1 inch range for machining, calibration, or quality control tasks.

Pros:

- High resolution of 0.001 inches ensures detailed and accurate readings.

- Fine adjustment knob allows for precise positioning during measurement.

- Magnetic base provides stability and flexibility with an overall height of 9 inches.

Cons:

- May be more expensive than basic dial indicators, suitable for advanced users.

- Requires careful handling to prevent magnetic interference with sensitive electronics.

- Limited measurement range of 0-1 inch might not suit larger measurement needs.

Magnetic Base for Dial Indicator

The Magnetic Base for Dial Indicator stands out for its powerful 176-pound pull force, providing a stable and secure platform during precise measurement tasks. Its high-quality aluminum construction guarantees durability, corrosion resistance, and long-term reliability. The 360° flexible adjustment pole allows for precise positioning and versatile measurement angles, adapting easily to different setups. Compatibility is broad, supporting most digital indicators with 9.5 mm clamping holes, and the ON/OFF magnet control optimizes magnet performance on various metal surfaces. Overall, this magnetic base delivers exceptional stability and flexibility, making it an essential tool for accurate, dependable measurements.

Best For: professionals and technicians who require stable, precise support for digital dial indicators during measurement tasks in industrial, machining, or calibration settings.

Pros:

- Provides a powerful 176 lbs pull force for maximum stability during use

- Constructed from durable, corrosion-resistant aluminum for long-lasting performance

- Features a 360° flexible adjustment pole for versatile positioning and measurement angles

Cons:

- May be heavier than simpler magnetic bases, impacting portability

- Compatibility limited to indicators with approximately 9.5 mm clamping holes

- Requires a metal surface for optimal magnet activation and performance

WEN 10711 Industrial-Strength Adjustable Magnetic Base for Dial Indicators

If you need a reliable magnetic base that offers both stability and versatility, the WEN 10711 Industrial-Strength Adjustable Magnetic Base stands out as an excellent choice for dial indicator users. It provides a secure mount, compatible with most dial indicators thanks to its universal 3/8-inch hole. The base measures 2.5 x 2 inches, suitable for various surfaces, and supports calibration, runout tests, and setup tasks. Its magnetic force of over 175 pounds ensures firm attachment, preventing wobbling. The two-arm system pivots and locks in 360 degrees, allowing precise positioning up to 15 inches high. Overall, it’s a sturdy, versatile, and dependable tool for precise measurements.

Best For: hobbyists, technicians, and professionals needing a durable, versatile magnetic base for precise dial indicator measurements and setup tasks.

Pros:

- Strong magnetic force of over 175 pounds ensures secure attachment and stability during use

- Fully adjustable two-arm system pivots, bends, and locks in 360 degrees for flexible positioning up to 15 inches high

- Compatible with most dial indicators thanks to universal 3/8-inch mounting hole and supports various measurement applications

Cons:

- Some users report threading issues with adjustment knobs affecting dial placement accuracy

- Actual magnetic force may be closer to 30 pounds depending on surface conditions, not the full 175 pounds rated

- Heavyweight construction, while sturdy, may be cumbersome for extended portability or frequent repositioning

Neoteck Dial Indicator and Magnetic Base Set

Designed for workshop professionals and serious hobbyists alike, the Neoteck Dial Indicator and Magnetic Base Set stands out with its high-precision measurement capabilities. It includes a dial indicator with 0.001-inch accuracy and a magnetic base capable of holding up to 176 pounds. The set features adjustable arms, a flexible rotary joint, and a universal shaft for precise positioning. Made with hardened stainless steel, it meets ASME/ANSI standards for durability. Ideal for measuring geometric accuracy, deformation, and alignment in various machinery, this set guarantees stable, accurate readings during setup and maintenance in diverse workshop environments.

Best For: workshop professionals, CNC operators, and serious hobbyists seeking precise measurement tools for setup, alignment, and quality control.

Pros:

- High-precision 0.001-inch measurement accuracy ensures reliable readings.

- Strong magnetic base with 176 lbs holding capacity provides stable positioning on metal surfaces.

- Durable construction with hardened stainless steel components meets ASME/ANSI standards.

Cons:

- Magnetic base may be too heavy or bulky for portable or lightweight applications.

- Clamping and adjustment mechanisms might require careful handling to avoid misalignment.

- Limited to metal surfaces of at least 30mm thickness, restricting use on thinner or non-metallic materials.

Magnetic Stand for Dial Indicators (MGBR-01)

For professionals seeking a reliable and versatile magnetic stand for dial indicators, the Magnetic Base MGBR-01 stands out with its strong magnetic grip and flexible adjustment features. It supports up to 176 lbs of pull force and features a 14.1-inch height with two adjustable arms, allowing precise positioning. Compatible with most dial and digital indicators, it offers easy one-knob control for smooth, 360-degree movement via rotary joints. Constructed mainly of metal, it’s durable, though some users report minor joint wobbling. Overall, it provides excellent value for its price, combining stability, adjustability, and affordability for various measurement and machining tasks.

Best For: professionals and technicians needing a versatile, stable magnetic stand for dial indicators in machining, calibration, and quality control tasks.

Pros:

- Strong magnetic base supports metal surfaces up to 30mm+ thick, providing reliable hold.

- Adjustable arms and rotary joints allow precise, flexible positioning with 360-degree movement.

- Constructed mainly of metal, offering durability and solid build quality at an affordable price.

Cons:

- Some users report loose joints or wobbling despite tight knobs, affecting stability.

- Magnetic pull force may be less than claimed, especially on thinner or painted surfaces.

- Occasional assembly or manufacturing inconsistencies can impact joint tolerances and overall durability.

Fowler 52-155-007-0 Surface Gage with 4 & 7 Spindle

The Fowler 52-155-007-0 Surface Gage with 4 & 7 Spindle stands out for its versatile spindle options and precise adjustment features, making it an excellent choice for professionals who need accurate measurements. Its spindles come in 4, 7, 9, and 12-inch lengths, providing flexibility for various tasks. Fine adjustments are easy with the knurled thumb screw, allowing quick, accurate settings at any angle. The ground steel base features a V-groove for round work and retractable pins for flat surfaces. Overall, this gage offers reliable precision and adaptable mounting options for diverse measurement needs.

Best For: Professionals and technicians requiring precise measurement and versatile mounting options for various machining and inspection tasks.

Pros:

- Offers multiple spindle lengths (4, 7, 9, and 12 inches) for versatile use

- Fine adjustment via knurled thumb screw ensures quick and accurate settings at any angle

- Ground steel base with V-groove and retractable pins provides secure mounting on round and flat surfaces

Cons:

- May be heavier or bulkier compared to smaller, more portable surface gages

- Limited to specific spindle lengths unless additional accessories are purchased

- Requires careful handling to maintain precision, especially with frequent adjustments

Dial Indicator with Magnetic Base and Point Inspection Set

If you’re looking for a versatile tool that combines precise measurement with ease of use, the Dial Indicator with Magnetic Base and Point Inspection Set is an excellent choice. It includes a 0-1 dial indicator with 0.001-inch graduation, a sturdy magnetic base with fine adjustment, and a 22-piece indicator point set for various inspection tasks. The magnetic base offers reliable stability and easy positioning, while the indicator’s dual dial faces provide clear readings. Ideal for woodworking, setup, and professional inspections, this set delivers accuracy and convenience. Its durable design and versatile components make it a valuable addition to any precision measuring toolkit.

Best For: DIY enthusiasts, woodworking professionals, and inspection technicians seeking precise measurement tools for setup and quality control.

Pros:

- Accurate 0.001-inch graduation for detailed measurements

- Magnetic base with fine adjustment for stable and precise positioning

- Versatile 22-piece indicator point set compatible with AGD specifications

Cons:

- Tolerance issues may require re-calibration for perfect accuracy

- Adjustments can be difficult for some users due to tight tolerances

- Durability of the indicator points may vary with frequent use

HDLNKAK Indicator Magnetic Base and Flex Arm Combo

The HDLNKAK Indicator Magnetic Base and Flex Arm Combo stands out thanks to its 360-degree flexible stem, allowing precise positioning of digital dial indicator gauges. Its strong magnetic base securely attaches to surfaces in any orientation—horizontal, vertical, or upside down—ensuring stability during measurement. The flexible arm offers versatile movement for ideal visibility and access. With a simple push-button on/off switch, I can easily adjust and lock the gauge in place with one hand, making setup quick and effortless. This combo is perfect for machinists and professionals who need a durable, reliable, and adaptable magnetic support system for accurate, precise measurements in various work environments.

Best For: machinists and professionals requiring a durable, flexible magnetic dial indicator holder for precise measurement tasks in various work environments.

Pros:

- Provides 360-degree flexible stem for optimal positioning and accessibility

- Strong magnetic base ensures secure attachment to surfaces in any orientation

- Easy one-handed adjustment with push-button on/off switch for quick setup

Cons:

- May be heavier or bulkier compared to smaller, less robust models

- Magnetic base could interfere with sensitive electronic components or surfaces

- Flex arm might require occasional tightening or adjustment to maintain positioning

Neoteck Digital Dial Indicator Gauge and Magnetic Base Set

For anyone seeking accurate and versatile measurement tools, the Neoteck Digital Dial Indicator Gauge and Magnetic Base Set stands out thanks to its high-resolution digital indicator and sturdy magnetic mounting. The set includes a digital dial indicator that measures up to 1 inch (25.4mm) with a resolution of 0.0005 inch (0.01mm), plus a durable magnetic base with two arms for flexible positioning. The magnetic base features on/off control and can handle tensile forces up to 176 lbs, ensuring stability on metal surfaces at least 30mm thick. Its compatibility with most indicators makes it ideal for tasks in workshops, CNC machines, and precision projects.

Best For: Hobbyists, small workshop professionals, and precision measurement enthusiasts seeking a versatile and reliable digital dial indicator with magnetic mounting.

Pros:

- High-resolution digital display with 0.0005 inch (0.01mm) accuracy for precise measurements

- Adjustable magnetic base with strong holding force up to 176 lbs for stable positioning

- Compatible with most dial and digital indicators, offering great versatility for various measurement tasks

Cons:

- Magnetic base requires metal surfaces at least 30mm thick for optimal stability

- Limited measurement range of only 1 inch (25.4mm), which may not suit larger measurements

- Some users may find the digital interface less intuitive compared to traditional analog indicators

HDLNKAK Dial Indicator with Magnetic Base

The HDLNKAK Dial Indicator with Magnetic Base stands out as an affordable choice for machinists and technicians who need reliable precision for light to moderate measurement tasks. It includes a dial indicator, magnetic base, gooseneck arm, and storage case, offering versatility and portability. The dial reads with a 1 mil (0.001 inch) sensitivity, suitable for precise setups like CNC routing. The magnetic base provides secure attachment and stability on metal surfaces, with a weight that enhances grip. Although the gooseneck arm can be tricky to adjust and may feel unstable, the overall build quality makes this set a solid option for budget-conscious professionals.

Best For: hobbyists, entry-level machinists, or technicians seeking an affordable and portable measurement tool for light to moderate precision tasks.

Pros:

- Affordable price point makes it accessible for budget-conscious users

- Includes a versatile set with a dial indicator, magnetic base, gooseneck arm, and storage case

- Suitable for precise setups like CNC routing with a 0.001 inch sensitivity

Cons:

- Gooseneck arm can be difficult to secure and may feel unstable during use

- Magnetic base’s strength is moderate and may not hold firmly under heavier forces

- The dial indicator’s plastic lens is prone to scratches and occasional sensitivity issues

WEN Magnetic Base for Dial Indicators

Looking for a magnetic base that offers industrial-strength stability and precision for dial indicators? The WEN Magnetic Base (Model 10714) delivers just that. It’s compatible with WEN dial indicators and features a universal 3/8-inch mounting hole, fitting most models. Its powerful magnet generates over 175 pounds of force, ensuring a secure attachment to ferrous surfaces, while the 2.5 by 2-inch v-groove keeps your tool stable. The adjustable three-arm system pivots 360 degrees and extends up to 14.5 inches, making positioning quick and precise. Easy to activate and disengage, this base combines strength, flexibility, and ease of use—making it a reliable choice for professional and DIY precision measurements.

Best For: professionals and DIY enthusiasts seeking a durable, precise magnetic base for dial indicators on ferrous surfaces.

Pros:

- Offers industrial-strength magnetic force over 175 pounds for a secure attachment

- Fully adjustable three-arm system with 360-degree pivoting and up to 14.5 inches reach

- Compatible with most dial indicators thanks to a universal 3/8-inch mounting hole

Cons:

- Heavier and bulkier compared to smaller, portable bases

- May require a ferrous metal surface for optimal magnetic grip

- Limited to use with ferrous surfaces, not suitable for non-magnetic materials

Factors to Consider When Choosing a Surface Gauges Magnetic Base

When choosing a magnetic base for a surface gauge, I consider its magnetic strength and how well it maintains during measurement. I also look at adjustability, compatibility with tools, and the overall build quality to guarantee durability. Size and weight are important too, since they affect ease of use and stability.

Magnetic Strength and Holding Power

Ever wondered how well a surface gauge stays in place during precise measurements? The key lies in its magnetic strength and holding power. A stronger magnetic base ensures the gauge remains stable on ferrous surfaces, especially when accuracy matters most. I recommend a magnetic pull force of at least 80 pounds for reliable grip, particularly on uneven or coated surfaces that can weaken magnetic adhesion. Keep in mind, surface finish, paint, or coatings may reduce magnetic effectiveness, so a more powerful magnet helps compensate. Many bases include on/off switches, allowing quick repositioning without losing magnetic hold. Durability of the magnetic field over time also matters; high-quality magnets tend to retain their strength longer, ensuring consistent accuracy during repeated use.

Adjustability and Flexibility Options

Choosing a magnetic surface gauge base with good adjustability can make a significant difference in measurement accuracy. Look for bases with multiple rotary joints or pivot points, enabling precise multi-directional adjustments. Adjustable arms should have secure locking mechanisms to hold their position during measurement, preventing drift that could skew results. Flexibility in arm length and articulation allows you to reach tight or awkward spaces easily, improving versatility. Consider bases with easy on/off magnetic switches for quick engagement and disengagement without losing calibration, saving time and ensuring consistent results. High-quality bases often feature durable materials and smooth, reliable joints that resist wear, maintaining their adjustability over time. These features help you achieve precise, reliable measurements in various working conditions.

Compatibility With Measurement Tools

Selecting a magnetic base that is compatible with your measurement tools is essential for guaranteeing accurate and reliable results. First, check that the clamping hole diameter matches your dial indicator or measurement device, with common sizes like 3/8 inch (9.52mm). The magnetic strength should be at least 80 lbs to hold the gauge securely during precise work. Also, verify that the mounting interface—such as lug back or flat back—fits your tool’s design. Make certain that the adjustable joints or arms can accommodate the angles and positions you need for your tasks. Finally, consider the base’s overall size and weight to strike a balance between stability and maneuverability, making sure it’s practical for your workspace and measurement requirements.

Build Quality and Durability

When evaluating surface gauge magnetic bases, build quality and durability are crucial for guaranteeing consistent, accurate measurements over time. High-quality bases are made from tough materials like hardened steel or aluminum, resisting wear from frequent use. Precise machining and tight tolerances in joints and locking mechanisms ensure stability and prevent slipping during measurements. The magnets should provide strong, reliable holding power on various surfaces, even uneven or painted metal. Durability also depends on the quality of locking and adjustment parts, which must withstand repeated operation without stripping or breaking. Additionally, corrosion-resistant finishes extend the lifespan of the base, maintaining both performance and appearance. Investing in a well-built, durable base means fewer replacements and more reliable precision in your measurement tasks.

Size and Weight Considerations

The size and weight of a magnetic base directly impact how well it fits into your workspace and how easy it is to handle during measurements. A smaller, lighter base is more portable and easier to position in tight or complex setups, making quick adjustments simpler. However, heavier bases generally provide better stability, reducing the risk of movement during measurement, especially on smooth or uneven surfaces. Larger, heavier bases often have stronger magnets, ensuring they stay securely in place. That said, they can be less convenient for quick repositioning or use in tight spaces. Balancing size and weight is key—opt for a lightweight, compact base if you need portability, but don’t sacrifice stability if precision is critical. Consider your workspace constraints and measurement needs carefully.

Ease of Operation and Setup

Ease of operation and setup are essential factors that can make or break your experience with a surface gauge’s magnetic base. A user-friendly magnetic base should have intuitive ON/OFF switches or control mechanisms that enable quick engagement and release from metal surfaces. Adjustable arms and rotary joints need to lock securely with minimal effort, allowing precise positioning without complicated adjustments. Clear, simple controls like single-knob mechanisms or fine-tuning screws help speed up setup and repositioning during measurements. The magnetic strength and stability should be easy to activate or deactivate, providing a reliable hold without requiring excessive force. Ergonomic handles or quick-release locks also enhance usability, reducing setup time and boosting efficiency on the job.

Price and Value Proposition

Choosing the right surface gauge with a magnetic base involves carefully balancing price and features to get the best value. Budget options tend to offer basic stability suitable for light-duty tasks, but they may lack the durability and magnetic strength needed for critical measurements. Premium models, while more expensive, often provide stronger magnets, improved adjustability, and higher build quality, which can justify the cost for professional use. When evaluating value, consider not just the initial price but also features like magnetic force, precision mechanisms, and materials. Additionally, factors like warranty, customer support, and potential repair costs over time play a role in overall value. Prioritizing these aspects ensures you choose a magnetic base that offers reliability and longevity for your specific needs.

Application Versatility

When selecting a surface gauge with a magnetic base, versatility is key to adapting to different measurement tasks. I look for models that can hold various tools like dial indicators, test indicators, or calipers, with compatible mounting options and adjustable arms. Supporting multiple surface types—flat, curved, or uneven—is essential, so I prefer bases with adjustable positioning and strong magnetic force to prevent slipping on different metal thicknesses. Compatibility with different mounting configurations, such as V-grooves or flat bases, helps me work on a wide range of workpieces. Ease of adjustment and quick repositioning are also critical, so I favor gauges with smooth locking mechanisms and flexible arms. This versatility ensures I can efficiently handle diverse measurement needs in any workspace.

Frequently Asked Questions

How Do Magnetic Bases Perform at Different Temperatures?

Magnetic bases perform well across various temperatures, but extreme heat or cold can affect their strength. When it’s very cold, the magnetic force might weaken slightly, making the gauge less stable. In high temperatures, magnets can lose some of their magnetism over time. I recommend checking the manufacturer’s specs for temperature ranges to guarantee accuracy. Overall, they work reliably within standard workshop conditions, but extreme temps require extra caution.

Are Magnetic Bases Compatible With All Dial Indicators?

Yes, magnetic bases are compatible with most dial indicators, but it’s essential to verify the indicator’s mounting specifications. Many dial indicators feature standard mounts that fit well with magnetic bases, making them versatile for various measurements. However, some specialized indicators might require adapters or unique mounts. I recommend confirming compatibility before purchasing to ensure a secure fit and accurate readings during your precision measurements.

What Is the Maximum Weight Magnetic Bases Can Support?

Magnetic bases typically support weights ranging from about 10 to 50 pounds, depending on the model. I’ve found that most quality magnetic bases can hold around 20 to 30 pounds securely. It’s essential to check the specific weight capacity listed by the manufacturer before using it. I always guarantee the surface is smooth and clean for maximum stability and safety when working with heavier or more precise measurements.

How Do Magnetic Bases Handle Uneven or Curved Surfaces?

Imagine trying to stick a magnet to a crumpled ball of foil—pretty tough, right? That’s how magnetic bases handle uneven or curved surfaces. They use powerful magnets and flexible joints to conform to irregular shapes, giving you stability. But don’t expect perfect adhesion everywhere. You’ll get better results on surfaces with some flatness or gentle curves, ensuring your measurements stay precise and reliable.

What Safety Precautions Should Be Taken When Using Magnetic Bases?

When using magnetic bases, I always guarantee the surface is clean and free of debris to prevent slipping. I wear safety goggles to protect my eyes from metal shavings or sparks. I also double-check the magnetic strength to avoid sudden releases. Handling the gauge carefully prevents accidental drops, which could damage the device or cause injury. Finally, I keep the work area organized to stay aware of my surroundings and avoid accidents.

Conclusion

Choosing the right magnetic base feels like finding a steady anchor in a sea of options. When I pick a surface gauge, I look for reliability and precision—like a lighthouse guiding my measurements through foggy uncertainty. With these top picks, you’ll have a sturdy foundation for accuracy, turning your measuring tasks into a dance of perfect alignment. Trust these tools to keep your work grounded and your results shining bright.