Understanding table saw blade geometry helps you choose the right blade for your project. ATB (Alternate Top Bevel) teeth are great for detailed crosscuts and fine finishes, while FTG (Flat Top Grind) teeth excel at rip cuts with minimal kerf. TCG (Triple Chip Grind) combines features to handle a variety of cuts efficiently. Knowing these shapes affects how your cuts turn out, so exploring them further can improve your woodworking results.

Key Takeaways

- ATB blades have beveled teeth alternating directions, ideal for crosscuts and detailed woodworking.

- FTG blades feature flat-topped teeth with 0° bevel, suited for rip cuts and minimal kerf loss.

- TCG blades combine ATB and FTG tooth designs for versatile cutting performance across various materials.

- Tooth angles typically range from 20° to 30°, influencing cut quality and tear-out resistance.

- Blade material (steel or carbide-tipped) impacts durability and suitability for different wood types and cutting tasks.

Understanding table saw blade geometry is essential for achieving precise cuts and ensuring safety during woodworking projects. When selecting a blade, you need to contemplate its blade material and cutting angles, as these factors directly influence performance and the quality of your work. The blade material determines durability and cutting efficiency; steel blades are common for general use, but carbide-tipped blades last longer and cut cleaner, especially with harder woods. The cutting angles, or tooth configurations, are equally important because they shape how the blade interacts with the material, affecting both the speed and accuracy of your cuts.

Choosing the right blade material and tooth angle is key for accurate, safe woodworking cuts.

Different blade tooth designs, such as ATB (Alternate Top Bevel), FTG (Flat Top Grind), and TCG (Triple Chip Grind), each have unique cutting angles that serve specific purposes. An ATB blade features teeth beveled in alternating directions, creating sharp points that excel at making clean crosscuts and detailed work. The cutting angles in ATB blades typically range from 20 to 30 degrees, providing a fine balance between smoothness and aggressive cutting. These angles allow the teeth to shear through wood fibers efficiently, reducing tear-out and delivering a cleaner finish. When you use an ATB blade, you’re leveraging a design that’s optimized for precision and a smooth cut, making it a reliable choice for detailed and finish carpentry.

FTG blades, on the other hand, feature teeth with a flat top and are primarily used for rip cuts and cutting with minimal kerf loss. The flat top grind has a 0-degree cutting angle, which means the teeth are straight across. This setup is less aggressive and produces fewer splinters, but it’s mainly suited for ripping along the grain rather than crosscutting. The blade material here also matters; a high-quality steel or carbide-tipped FTG blade ensures durability and consistent performance, especially when you’re working on larger projects that require repetitive cuts.

The TCG design combines features of both ATB and FTG blades, with alternating teeth set at different cutting angles—usually 30 degrees for the ATB teeth and 10 degrees for the flat-top teeth. This configuration allows the blade to handle a variety of cuts, including crosscuts and ripping, with enhanced durability and chip clearance. The cutting angles in TCG blades are optimized for multi-purpose use, especially when you’re tackling diverse projects that involve different types of cuts. The blade material used in TCG blades also influences how well they perform and how long they last under heavy use.

Additionally, understanding the market availability of these blades can help you choose the most suitable one for your woodworking needs, balancing cost and performance.

DEWALT 10-Inch Miter / Table Saw Blade, ATB, Thin Kerf, 5/8-Inch Arbor, 24-Tooth (DW3112)

Thin kerf for fast and smooth cutting action

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Does Blade Geometry Affect Cut Quality in Different Materials?

Your blade geometry directly impacts cut quality across various materials. For example, a blade with sharp, alternating teeth like ATB improves cuts in plywood and veneer, while FTG blades excel in cross-cutting hardwoods. Tooth configuration, combined with blade material, influences chip removal and finish smoothness. Selecting the right combination guarantees cleaner, more precise cuts, reducing splintering and tear-out, especially when you’re working with delicate or dense materials.

Can Blade Geometry Influence the Lifespan of a Table Saw Blade?

Yes, blade geometry can influence the lifespan of your table saw blade. For example, ATB blades tend to have better blade durability for crosscutting, but may require more maintenance to keep their edge sharp. Conversely, FTG blades are durable for ripping and often need less frequent maintenance. Proper maintenance, like cleaning and sharpening, extends blade life regardless of geometry, ensuring ideal performance and reducing replacement costs.

Are Certain Blade Geometries Better for Specific Woodworking Projects?

Sure, some blade geometries are like your woodworking BFFs, perfect for specific projects. For instance, ATB blades excel at crosscutting, giving you clean edges, while FTG blades are great for rip cuts. Your choice depends on blade material and how often you sharpen it—because even the best blade needs love. Pick wisely, and your projects will turn out as beautiful as a polished, sharpened blade slicing through butter.

How Does Blade Angle Impact the Safety of Cutting Operations?

Your blade angle considerably impacts safety considerations during cutting. A steeper blade angle can cause increased kickback, so you should choose an appropriate angle for your project. Maintaining a proper blade angle helps guarantee cleaner cuts and reduces the risk of binding or kickback. Always follow safety guidelines, keep your hands clear, and verify the blade angle before cutting to protect yourself and achieve precise results.

Can Changing Blade Geometry Improve Cutting Efficiency and Reduce Waste?

Think of changing blade geometry as tuning a musical instrument; it can dramatically improve your performance. By selecting the right blade design, you enhance cutting speed and precision, which reduces waste and boosts efficiency. This also promotes blade durability, as the right geometry minimizes stress and wear. You’ll find your cuts cleaner and faster, turning your woodworking into a symphony of smooth, efficient, and waste-free craftsmanship.

Amana Tool Carbide Tipped Glue Line Ripping Circular Saw Blade, 610301, 10 Inch D x 30T TCG, 22 Deg, 5/8 Bore

GLUE-LINE RIP FINISH TABLE SAW BLADE: Leaves edges ready to glue—no sanding or jointing; for table saws, sliding…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Now that you understand the differences between ATB, FTG, and TCG blades, you’ll make smarter choices for your projects. Remember, like a well-armed knight of yore, choosing the right blade guarantees precision and safety. Whether you’re crafting furniture or delicate veneers, knowing your blade geometry is your secret weapon. So, keep these insights in mind, and don’t let your woodworking endeavors become a tragic tale of missteps. Happy cutting, and may your skills stand the test of time!

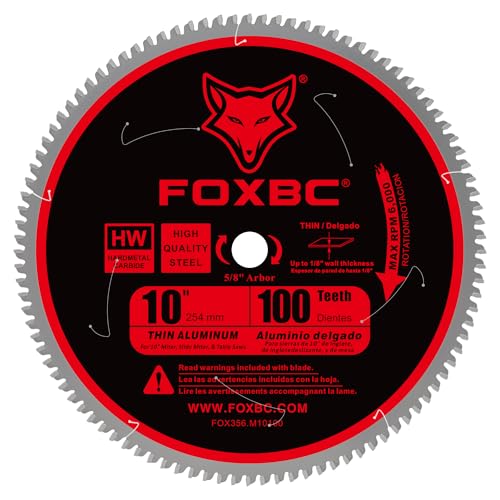

FOXBC 10-Inch Saw Blade 100-Tooth TCG for Aluminum and Non-Ferrous Metal Cutting with 5/8-Inch Arbor

10 Inch 100-Tooth TCG Thin Aluminum Metal Cutting Saw Blade , KERF 0.095", 5/8" Arbor

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

WEN BL1080 10-Inch 80-Tooth Carbide-Tipped Ultra-Fine Finish Professional Woodworking Saw Blade for Miter Saws and Table Saws

Featuring a 10-inch diameter (254 mm), a 5/8-inch arbor (15.88 mm) and a rating of up to 6000…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.