When choosing a sharpening system, you’ll find oil stones, water stones, and diamond plates each suited for different needs. Oil stones are versatile and use honing oil to carry away metal, making them good for reshaping edges. Water stones cut quickly and require water, ideal for fast sharpening, while diamond plates are the most aggressive and remove material rapidly. Understanding their differences helps you pick the right tool—continue to explore how each system can improve your sharpening skills.

Key Takeaways

- Oil stones use honing oils to reduce friction and carry away metal particles, extending their lifespan.

- Water stones offer rapid cutting and are easy to use but require regular flattening and water lubrication.

- Diamond plates provide the fastest, most aggressive sharpening without oils or water, ideal for quick repairs.

- Proper technique involves maintaining a consistent angle and light strokes across all systems for optimal results.

- Lubricants like oils or water are essential for reducing friction and preventing clogging, depending on the system.

Have you ever wondered how professionals keep their blades razor-sharp and ready for any task? The secret lies in understanding the importance of proper sharpening systems and techniques. One of the most critical aspects is maintaining the correct edge geometry, which ensures your blade performs at its best and stays sharp longer. When sharpening, you’ll want to pay close attention to the angle at which you hone your blade, as this directly affects edge durability and cutting efficiency. Consistent edge geometry is key, and that’s where the right sharpening tools come into play.

Using honing oils is an essential step, especially with oil stones. These oils serve multiple purposes—they reduce friction, carry away metal particles, and prevent the stone from clogging. Applying a few drops of honing oil to your oil stone creates a smooth, slick surface that allows for more controlled, even sharpening. This not only preserves the integrity of the edge but also prolongs the life of your sharpening stone. By ensuring a clean, lubricated surface, you can better maintain the desired edge geometry and avoid unwanted dulling or uneven wear on your blade.

Honing oils reduce friction, carry away metal particles, and extend your sharpening stone’s lifespan.

Oil stones are traditional and versatile, offering a slow, deliberate sharpening process that’s excellent for reshaping and refining edges. They often come in various grit levels, allowing you to start with a coarse stone to reshape a dull edge and progress to finer grits for polishing. When you sharpen, focus on maintaining a consistent angle—usually around 20 degrees for most kitchen knives—and use light, even strokes. The oil helps to keep the abrasive particles in suspension, making the process smoother and more efficient. With patience and proper technique, you’ll achieve a razor-sharp edge that’s precisely suited to your needs.

Water stones are another popular choice, known for their rapid cutting ability and ease of use. They require water instead of oil, which makes cleanup simpler. While water stones don’t typically need honing oils, they do demand frequent flattening to keep the surface even and effective. For both water and oil stones, the key is to understand how to control your angle and pressure, ensuring that the edge remains consistent throughout the process. This consistency helps you maintain the correct edge geometry, avoiding uneven bevels that can weaken the blade.

Diamond plates are the most aggressive and fastest option, often used for quick repairs or initial sharpening. They don’t require honing oils or water, but their coarse surface can remove material quickly, so use them carefully. After using a diamond plate, moving to a finer stone can help refine the edge and bring it to a razor-sharp finish. No matter which system you choose, understanding how to preserve proper edge geometry and using the appropriate lubricants will make all the difference in achieving professional-level sharpness.

YeopAsda Knife Sharpening Stone Set – Premium 4 Side Grit 400/1000 3000/8000 Whetstone Sharpener Kit – Non-Slip Bamboo Base,Cut Resistant Gloves, Angle Guide,Flatting Stone,Honing Guide,Leather Strop

🎁【Affordable & ideal gift】The sharpening stones for knives is the most original sharpening tool and it comes with…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Do I Choose the Right Sharpening System for My Needs?

You should choose a sharpening system based on your blade material and sharpening frequency. If you have high-carbon or tougher blades and sharpen often, a diamond plate offers quick, durable results. For softer blades or occasional sharpening, water stones provide a finer edge with less effort. Consider how often you sharpen, your budget, and comfort with maintenance to pick the system that best suits your needs.

What Is the Typical Lifespan of Each Sharpening Stone Type?

You’ll find that oil stones last around 10-15 years with proper care, thanks to their durability and infrequent maintenance. Water stones tend to wear faster, needing resurfacing every few months, which affects their lifespan. Diamond plates are highly durable, often lasting decades without significant wear, but they require occasional cleaning to maintain their efficiency. Regular maintenance intervals are key to extending each stone’s lifespan and ensuring consistent sharpening results.

Can I Use Water Stones on All Types of Knives?

Yes, you can generally use water stones on most knives, but you should check their compatibility first. Water stones work well with high-carbon, stainless, and ceramic blades, offering a smooth sharpening technique. However, some specialty knives or those with specific coatings may require different systems. Always verify your knife’s material and follow the recommended sharpening method to avoid damage and achieve ideal results.

Are Diamond Plates Safe for Delicate or Vintage Blades?

Diamond plates are generally safe for delicate or vintage blades if you use light pressure and proper technique. Their durability means they last long and can handle various blades, but you should be cautious with delicate blade care. Excessive force may cause damage, so take your time and use gentle strokes. This way, you protect your vintage blades while benefiting from the diamond plate’s durability for effective sharpening.

How Often Should I Replace or Refurbish My Sharpening Stones?

You should replace or refurbish your sharpening stones when they become uneven, develop deep grooves, or no longer produce a consistent edge. Regular stone maintenance extends their lifespan, but sharpening frequency also affects how often you need new stones. If you notice your edges aren’t improving despite proper sharpening, it’s time to evaluate your stones’ condition. Proper care ensures peak performance and prolongs their usability, saving you money and effort in the long run.

WEN BG4270T 10-Inch Two-Direction Water Cooled Wet/Dry Sharpening System

Features a 10-inch 220 grit sharpening stone and an 8-inch leather-stropping wheel

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Now that you understand the differences between oil stones, water stones, and diamond plates, you’re better equipped to choose the right sharpening system. Imagine restoring a beloved chef’s knife, feeling the thrill as it slices effortlessly again—saving you time and frustration. Whether you’re a hobbyist or professional, mastering these tools guarantees your blades stay sharp and reliable. With the right system, you’ll turn dull edges into precision tools, making every cut satisfying.

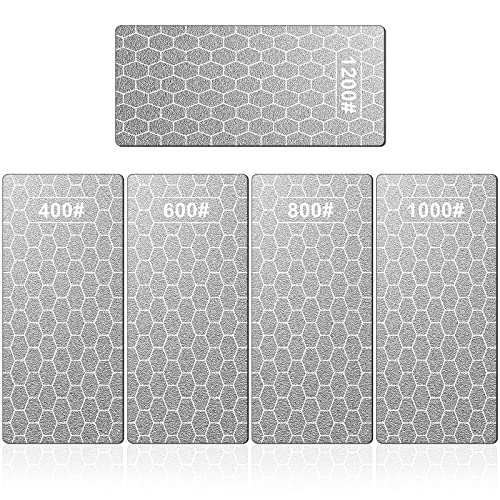

Diamond Sharpening Stone, 5 Pcs Knife Sharpening Stone with Extra Fine/Coarse Plate and Non-slip Base, 400/600/800/1000/1200 Grit

Unique Honeycomb Design:The sharpening stone set with unique honeycomb design ensures that the dust generated during the grinding…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Intelitopia Complete Knife Sharpening Stone Set – Dual Grit Whetstone 400/1000 3000/8000 Knife Sharpener with Leather Strop, Flattening Stone, Bamboo Base, 3 Non-slip Rubber Bases & Angle Guide

【Complete Knife Sharpening Stone Kit】You don't need to be a Pro to sharpen your blades, all you need…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.