To micro-adjust machines, you use feeler gauges and setup blocks together for precise measurements. Feelers gauges help you verify tiny gaps and make fine-tuned changes, while setup blocks provide a reliable reference point to guarantee components are correctly spaced. By combining these tools, you can accurately set and align parts, improving machine performance and reliability. Keep going to discover how mastering these tools can optimize your adjustments and results.

Key Takeaways

- Feeler gauges measure tiny clearances to enable precise micro-adjustments in machine components.

- Setup blocks serve as reliable reference points for accurate distance setting during machine calibration.

- Using both tools together ensures micro-level adjustments with high accuracy and repeatability.

- Proper calibration and maintenance of these tools prevent measurement drift and enhance adjustment precision.

- Combined use allows for detailed, incremental tuning, optimizing machine performance and component alignment.

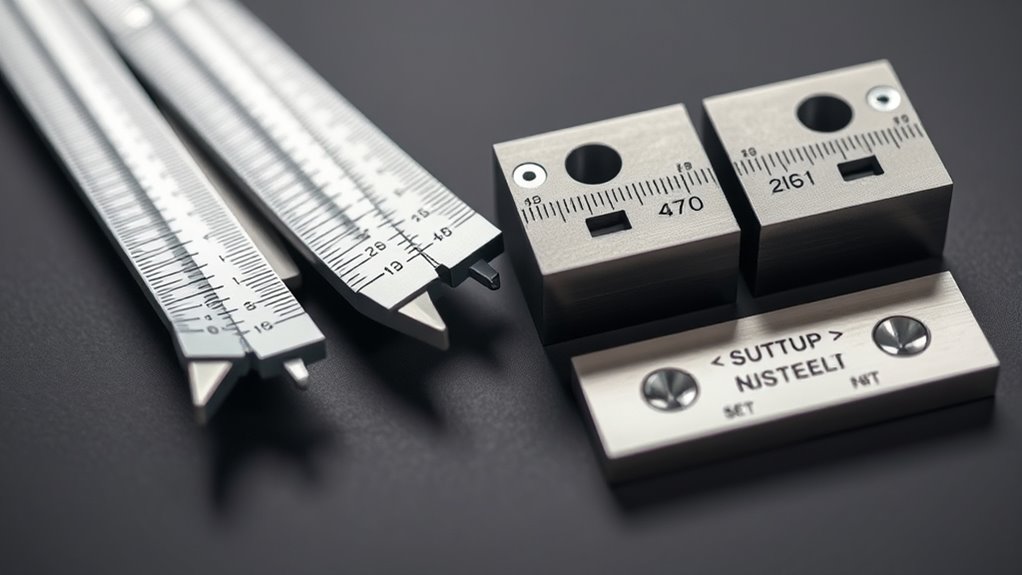

Feeler gauges and setup blocks are crucial tools for precision measurement and machine setup. When working with machinery that demands tight tolerances, accuracy is everything. You need to make certain that each component is positioned correctly and that your measurements are spot-on. This is where feeler gauges come into play. They allow you to measure tiny gaps or clearances with high precision, making sure your machine parts align perfectly. Without proper measurement, your machine’s performance could suffer, leading to inaccurate results or even damage. That’s why you must use tools like feeler gauges to verify and maintain the correct spacing, guaranteeing your setup is precise. Regular cleaning and maintenance of these tools can also improve their accuracy over time. Tool calibration is critical during setup to guarantee that your measurements are reliable. When you use feeler gauges, you’re fundamentally calibrating your understanding of the gap sizes, which helps you make micro-adjustments that fine-tune your machinery. For example, if you’re setting the valve clearance on an engine or adjusting the gap on a precision instrument, using feeler gauges helps you achieve the exact clearance specified. Proper calibration ensures each measurement is accurate, reducing errors down the line. It’s an ongoing process where regularly checking and verifying your tools’ accuracy prevents drifts in measurement that can compromise your work. Setup blocks complement feeler gauges by providing a solid reference point during machine setup. They are used to set precise distances between machine parts or to calibrate tools to specific dimensions. When you position setup blocks, you can quickly and accurately establish reference points, which saves you time and reduces guesswork. They’re especially useful when you need to replicate measurements across multiple setups or confirm that a machine’s components are aligned within tolerances. By combining setup blocks with feeler gauges, you gain a dependable method of micro-adjusting your machines, ensuring each component is perfectly aligned and functioning flawlessly. Using these tools together, you can perform detailed, precise adjustments that improve the overall accuracy of your work. Whether you’re setting up an industrial machine or calibrating a small precision instrument, understanding how to utilize feeler gauges and setup blocks is essential. They allow you to make incremental changes that would be impossible to achieve with standard tools or rough measurements. This meticulous approach to setup and measurement guarantees your machinery operates at its peak, delivering consistent results. Ultimately, mastering their use elevates your craftsmanship, ensuring every detail is measured and calibrated correctly for the best possible performance. Additionally, understanding the importance of proper bulb maintenance can extend the lifespan and performance of your equipment, ensuring consistent operation over time.

Frequently Asked Questions

How Do I Select the Right Feeler Gauge Thickness?

You select the right feeler gauge thickness by first determining the precise measurement you need for your setup. Use a gauge that fits snugly without forcing, guaranteeing accurate precision measurement. Always check your gauges regularly for wear and perform gauge maintenance to keep them accurate. Starting with a slightly thinner gauge and gradually increasing ensures you find the perfect fit, leading to better machine adjustments and consistent results.

What Materials Are Setup Blocks Typically Made From?

Setup blocks are typically made from materials like hardened steel, aluminum, or brass, chosen for their durability and precision. You should select a material that preserves its shape under pressure to ensure consistent measurements, especially when working with tight manufacturing tolerances. Hardened steel offers high durability, while aluminum and brass are lightweight and resistant to corrosion. Your choice depends on the specific durability needs and precision requirements of your setup.

How Often Should Feeler Gauges Be Calibrated?

Think of gauge calibration like tuning a musical instrument—you need to do it regularly to stay in harmony. You should calibrate feeler gauges every 6 to 12 months, depending on usage and environment. Regular setup block maintenance also ensures accuracy. By routinely checking and calibrating your gauges, you keep your measurements precise, preventing errors and ensuring your machine’s performance remains of the highest caliber.

Can Feeler Gauges Measure Non-Metallic Materials?

Yes, feeler gauges can measure non-metallic materials, but you need to verify gauge compatibility. Non-metallic measurement often requires specific gauges made from materials like plastic or rubber, which won’t damage delicate surfaces. Always check the gauge’s specifications to confirm it’s suitable for non-metallic materials. Using the correct gauges helps maintain accuracy and prevents damage, ensuring precise measurements for your projects.

What Are Common Mistakes in Using Setup Blocks?

You often make mistakes in setup blocks by not ensuring proper placement, which hampers precision alignment and reduces setup accuracy. Avoid rushing through the process; double-check that the blocks are seated correctly and free of debris. Using incorrect sizes or mixing up measurement units also causes errors. Always verify measurements before proceeding, and handle setup blocks carefully to maintain consistent, accurate results during machine adjustments.

Conclusion

By mastering feeler gauges and setup blocks, you gain precise control over your machine adjustments. These tools are your secret weapon for smooth, accurate operation, helping you avoid costly mistakes. Remember, a stitch in time saves nine—taking the extra moment to set up correctly pays off in the long run. Keep honing your skills, and you’ll find that precision isn’t just a goal but a habit that keeps your work sharp and reliable.