To transfer measurements accurately between workpieces, start by ensuring your tools are properly calibrated and in good condition. Use precise tools like calipers or rulers with clear markings, and double-check your measurements before transferring. Make sure your measurement tools are stable and visible during the process. Maintain consistency by comparing measurements with known standards or calibration references. Proper technique and well-maintained tools help minimize errors, so if you want to improve your accuracy further, keep exploring these essential steps.

Key Takeaways

- Use calibrated measuring tools to ensure the accuracy of transferred measurements.

- Mark reference points precisely on the first workpiece before transferring.

- Choose measurement tools appropriate for the required precision level.

- Maintain consistent measurement techniques, such as steady hand and proper tool positioning.

- Verify transferred measurements by double-checking before proceeding with cuts or assembly.

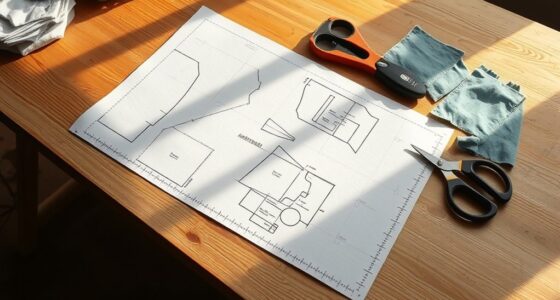

Transferring measurements is a fundamental skill that allows you to accurately replicate lengths, sizes, or quantities from one context to another. Whether you’re working on a woodworking project, metal fabrication, or any craft that demands precision, mastering how to transfer measurements correctly is vital. The key to success lies in understanding and applying effective calibration techniques and choosing the right measurement tools. Calibration techniques help guarantee your measurement tools are accurate, which is essential when transferring measurements. Over time, measurement tools can drift from their original calibration due to wear, temperature changes, or mishandling. Regular calibration, whether through comparison to a known standard or by using calibration devices, helps maintain their precision. For example, a digital caliper might need periodic zeroing to guarantee that it reads correctly at zero, or a tape measure should be checked against a standard length periodically. This process minimizes errors and guarantees that your transferred measurements remain reliable.

When it comes to measurement tools, selecting the appropriate device for your task is vital. For transferring measurements, tools like rulers, calipers, micrometers, and depth gauges are common. Each tool offers specific advantages; for instance, calipers provide versatility for both internal and external measurements, while micrometers excel in measuring small dimensions with high precision. Using the right tool also involves understanding its limitations and calibration status. Always verify that your measurement tools are in good condition—free of damage, dirt, or wear—and properly calibrated. This guarantees that when you transfer a measurement from one workpiece to another, you’re doing so with confidence. Additionally, understanding the contrast ratio of your tools can help ensure that your measurements are clearly visible and precise during transfer.

Frequently Asked Questions

What Tools Are Best for High-Precision Measurement Transfer?

For high-precision measurement transfer, you should use precision tools like dial indicators, height gauges, and coordinate measuring machines (CMMs). These tools guarantee accurate transfer of measurements between workpieces. Mastering transfer techniques, such as consistent setup and careful handling, also enhances accuracy. Combining quality precision tools with proper transfer methods guarantees you achieve exact measurements, minimizing errors and ensuring your workpieces meet tight specifications effectively.

How Can Temperature Fluctuations Affect Measurement Accuracy?

Temperature fluctuations can throw your measurements off like a boat in choppy waters. When temperatures change, thermal expansion causes workpieces and measurement tools to expand or contract, leading to inaccuracies. To keep your measurements precise, guarantee environmental stability by controlling room temperature and using materials with low thermal expansion. This way, you minimize the impact of temperature differences and maintain the accuracy needed for high-quality work.

What Are Common Causes of Measurement Transfer Errors?

You often encounter measurement transfer errors due to inconsistent calibration procedures or improper technique. When you skip calibration, your measurements lack accuracy, leading to errors. Additionally, if you don’t follow consistent methods, it affects measurement consistency. Handling tools improperly or rushing the process can also introduce inaccuracies. To minimize these issues, always verify your calibration regularly and follow standardized procedures, ensuring precise and reliable measurement transfer between workpieces.

How to Calibrate Measurement Tools for Transfer Accuracy?

Imagine your measurement tools as a finely tuned orchestra; calibration procedures are the conductor’s baton, ensuring harmony. To calibrate for transfer accuracy, you follow standardized measurement standards, aligning your tools against known references. Regular calibration checks, using certified gauges, keep your instruments precise. This process corrects deviations, like tuning a musical instrument, so your measurements stay true across different workpieces, guaranteeing consistency and reliability every time.

Are Digital Tools More Reliable Than Manual Methods?

Digital tools like digital calipers are generally more reliable than manual methods because they provide precise, quick readings consistent with measurement standards. You can easily calibrate digital calipers to guarantee accuracy, making them ideal for transferring measurements between workpieces. While manual tools require more skill and can be prone to human error, digital options help you maintain high standards, making certain your measurements stay consistent and accurate every time.

Conclusion

Now that you’ve mastered transferring measurements, think of it as passing a delicate torch—steady and precise. With each careful transfer, you’re weaving a thread that connects your workpieces like a tapestry of accuracy. Remember, your attention to detail is the compass guiding you through this intricate dance. Keep your focus sharp, and let your measurements flow smoothly—turning your craftsmanship into a symphony of precision that stands the test of time.