To decode wood grain direction like a pro, start by inspecting the surface for lines or streaks that show the grain flow. Feel with your fingertips to sense if the surface is smooth or resistant in different directions, and look at the end grain to see the fiber pattern—vertical indicates the grain direction. Cutting along the grain minimizes splintering, so understanding these signs helps you plan cleaner cuts. Keep exploring these techniques to sharpen your skills even further.

Key Takeaways

- Inspect the surface for visible lines or streaks indicating the grain flow; straight lines suggest aligned grain.

- Feel the surface with your fingertips, moving in different directions to detect resistance or smoothness that reveals grain orientation.

- Check the end grain for fiber patterns; vertical fibers typically indicate the grain direction.

- Observe how the wood surface reacts when you run your hand along it—smoother movement usually follows the grain.

- When cutting, align the saw blade to follow the grain to minimize tear-out and achieve cleaner, smoother results.

Ever wondered how to determine the direction of wood grain? Understanding grain orientation is essential for achieving cleaner cuts and better results in your woodworking projects. When you know how the grain runs, you can plan your cuts more effectively, reduce splintering, and improve the overall quality of your work. The key is to observe the wood carefully and choose the right woodworking techniques based on the grain’s direction.

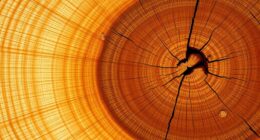

Start by inspecting the surface of your wood piece. Look for the lines or streaks that run across it; these are visual clues to the grain pattern. Sometimes, the grain is straight and consistent, while other times it may be wavy or irregular. Feel the surface with your fingertips—grain tends to feel smoother or more resistant in certain directions. Running your hand along the surface in different directions can help you feel whether the grain is running parallel or perpendicular to your intended cut. When you cut with the grain, your saw moves smoothly, but cutting against it often results in splinters or rough edges.

Another way to determine grain orientation is to examine the end grain. Check the cut edges of your wood; the pattern of the fibers there can reveal the grain’s direction. If the fibers run vertically, your grain is aligned that way. Knowing this helps you decide whether to make your cut along the grain, which is usually easier and produces a cleaner finish, or across it, which might be necessary for certain joinery or shaping techniques. Additionally, understanding the grain direction can help you select the appropriate saw blade and cutting technique to minimize tear-out and achieve a smoother cut.

Frequently Asked Questions

How Does Grain Direction Affect Different Types of Woodworking Projects?

Understanding how grain flow and wood texture impact your woodworking projects is vital. When you follow the grain direction, you get cleaner cuts and smoother finishes, especially on detailed work. Running your tools against the grain can cause splintering and rough surfaces. By paying attention to the grain flow, you guarantee better control, reduce waste, and achieve professional results, regardless of whether you’re crafting furniture, flooring, or decorative pieces.

Can Grain Patterns Be Altered or Manipulated for Aesthetic Purposes?

You can do some grain pattern manipulation for aesthetic grain alteration by carefully selecting and positioning wood pieces. Techniques like bookmatching, veneer inlay, or applying stains can create visual effects that enhance the wood’s natural beauty. While you can’t fundamentally change the grain direction, these methods allow you to achieve unique and attractive patterns, giving your project a personalized and professional look through aesthetic grain alteration.

What Tools Are Best for Detecting Subtle Grain Directions?

Imagine you’re holding a magnifying glass, revealing hidden secrets in the wood’s surface. The best tools for detecting subtle grain directions are a grain finder or a marking gauge with sharp, precise tips. These tools enhance your accuracy, allowing you to follow the natural flow of the grain pattern. With sharp eyes and accurate tools, you can easily identify the grain pattern, ensuring cleaner cuts and a professional finish every time.

How Does Grain Orientation Influence the Finishing Process?

Grain orientation directly affects your finishing process by influencing surface smoothness and grain contrast. When you sand or stain along the grain, you attain a smoother finish and better color contrast. Conversely, going against the grain causes roughness and uneven stain absorption. By understanding the grain direction, you guarantee cleaner cuts and a polished look, making your project look professional and refined. Properly aligning your work with the grain is essential for quality results.

Are There Safety Concerns Related to Cutting Against the Grain?

Like walking a tightrope, cutting against the grain can be risky. You need to stay alert and follow safety precautions to prevent injury. When you cut against the grain, the wood can tear and splinter unpredictably, increasing the risk of slips or cuts. Always wear safety gear, keep your tools sharp, and cut carefully to guarantee injury prevention. Safety should be your guiding star on every project.

Conclusion

Mastering wood grain direction helps you make cleaner cuts every time. Just imagine you’re building a custom bookshelf; by decoding the grain, you avoid splintering and achieve a smooth finish. For example, a DIY enthusiast struggled with rough edges until they learned to identify the grain, transforming their project. With a keen eye and practice, you’ll cut confidently and professionally, ensuring your woodworking projects look polished and precise. Decode the grain—your craftsmanship will thank you.