Quartersawn lumber resists cupping because its microscopic grain structure and fiber orientation promote even moisture distribution. The grains run mostly perpendicular to the board’s face, forming tight, straight lines that minimize internal stresses from humidity changes. This uniform fiber arrangement helps the wood expand and contract uniformly, reducing warping and maintaining stability. If you want to understand how this microscopic arrangement works to keep your projects straight and true, keep exploring further.

Key Takeaways

- Grain runs perpendicular to the face, reducing internal stresses during moisture fluctuations.

- Fibers are aligned radially, distributing internal stresses evenly and minimizing warping.

- Tightly packed fibers create a uniform cellular structure resistant to dimensional changes.

- Rays and fibers evenly distribute internal stresses, preventing localized deformation.

- Microscopic fiber orientation limits expansion and contraction, maintaining flatness and stability.

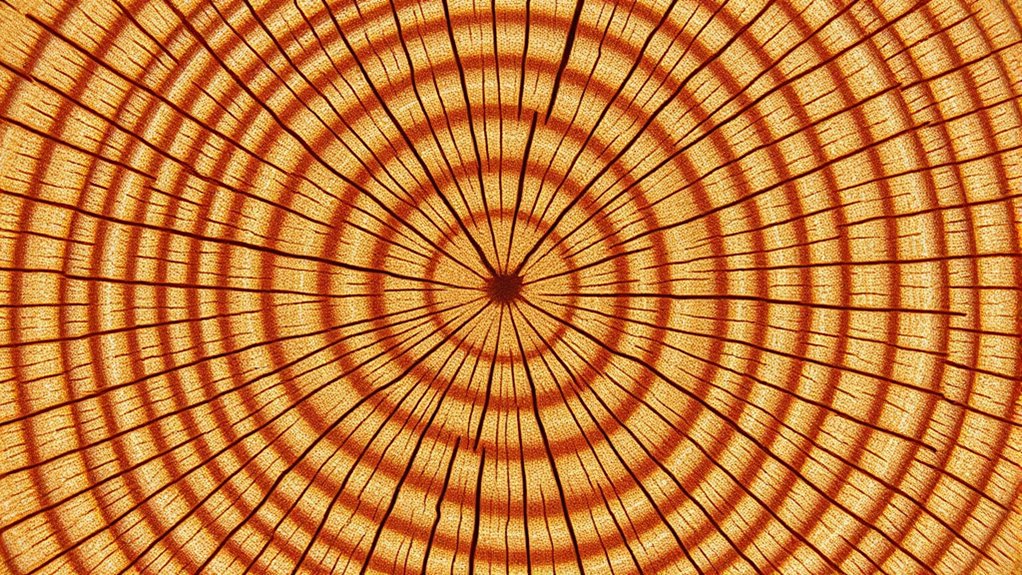

If you want your woodworking projects to stay flat and stable over time, choosing quartersawn lumber is a smart move. This type of wood has a distinctive grain orientation that plays an essential role in its resistance to cupping and warping. When you look closely at quartersawn lumber, you’ll notice the grain runs mostly perpendicular to the board’s face, often appearing as tight, straight lines or rays. This orientation is fundamental to understanding why it offers superior wood stability compared to other cuts, like flatsawn lumber. The way the grain is aligned influences how the wood responds to changes in humidity and temperature, making it less prone to distortion. At a microscopic level, the grain orientation of quartersawn lumber means that the wood fibers and cells are aligned in a way that minimizes movement. When moisture levels fluctuate, the fibers tend to expand or contract uniformly, reducing internal stresses that cause cupping. Unlike flatsawn boards, where the grain runs parallel to the board’s width, quartersawn wood has fibers that are more evenly distributed across the cross-section. This uniformity helps prevent uneven swelling or shrinking, which typically leads to cupping — the warping that causes the edges of a board to curl upward or downward. The cellular structure of quartersawn lumber contributes significantly to its stability, as the arrangement of fibers and rays mitigates internal stresses during moisture changes. Wood stability is heavily influenced by the way the fibers and cellular structure interact with moisture. In quartersawn lumber, the grain orientation results in fewer internal stresses during moisture changes, because the fibers are oriented more radially. This reduces the likelihood of the wood checking or cracking as it dries or absorbs moisture. You’ll find that this stability translates into less movement over time, making quartersawn lumber ideal for projects that demand precision and longevity, like furniture or fine cabinetry. The microscopic view shows tightly packed fibers with a regular, predictable pattern that resists distortion when exposed to environmental shifts. Furthermore, the microscopic structure of quartersawn lumber contributes to its durability. The rays and fibers are aligned in a way that distributes stress evenly, preventing localized weak spots that could lead to cupping. This uniformity keeps the surface flat and smooth, giving your finished project a more professional appearance. When you choose quartersawn lumber, you’re leveraging this microscopic architecture to ensure that your woodworking results stay true to your design, with minimal warping or cupping over time. In essence, understanding the grain orientation at a microscopic level reveals why quartersawn lumber offers unmatched stability and makes it the preferred choice for high-quality, enduring craftsmanship.

Frequently Asked Questions

How Does Moisture Content Influence Quartersawn Lumber’S Stability?

Moisture content plays a vital role in quartersawn lumber’s stability. As the wood approaches moisture equilibrium with its environment, it minimizes movement. Proper moisture levels help control shrinkage, reducing the risk of warping or cupping. When you maintain consistent moisture content, you guarantee the wood stays stable and less prone to distortion, making it easier to work with and ensuring long-lasting, quality results in your projects.

Can Quartersawn Lumber Warp Over Time Despite Its Resistance?

Yes, quartersawn lumber can warp over time despite its resistance, mainly due to changes in moisture content. Grain orientation helps it resist cupping initially, but uneven moisture absorption or loss causes internal stresses. Wood density also influences stability; denser wood may resist warping longer. However, environmental fluctuations can still lead to slight warping or twisting, especially if the wood isn’t properly sealed or maintained.

Are There Specific Wood Species Better Suited for Quartersawn Cuts?

When choosing wood species for quartersawn cuts, you want species that naturally resist warping, cracking, and cupping. Hardwoods like oak, hickory, and maple, with tight, consistent grain patterns, are excellent options. These species maintain their stability over time, thanks to their dense, uniform grain. By selecting the right wood species with favorable grain patterns, you guarantee your quartersawn lumber remains durable, beautiful, and resistant to deformation.

How Does Kiln Drying Affect the Cupping Resistance of Quartersawn Lumber?

When kiln drying quartersawn lumber, you improve its cupping resistance through effective moisture control. Proper drying methods remove excess moisture uniformly, reducing internal stresses that cause warping. By carefully controlling temperature and humidity levels during kiln drying, you guarantee the wood reaches a stable moisture content, which helps maintain its flatness and dimensional stability. This process makes quartersawn lumber less prone to cupping over time, enhancing its durability and appearance.

What Tools Are Best for Identifying Quartersawn Versus Other Cuts?

Identifying quartersawn lumber is like reading a detailed map of grain orientation. You’ll want to use a good eye for visual inspection, focusing on the grain’s pattern—rays running parallel to the face indicate quartersawn cuts. Tools like a magnifying glass or a sharp chisel help verify grain direction. These methods guarantee you distinguish quartersawn from plain- or riftsawn, guiding you toward stable, cupping-resistant wood.

Conclusion

Understanding why quartersawn lumber resists cupping is like revealing nature’s secret armor for wood. By choosing this grain orientation, you’re planting a sturdy shield against warping and twisting, letting your projects stand tall and proud. Think of it as giving your wood a suit of armor that’s both beautiful and resilient. So, when you pick quartersawn, you’re not just making a wise choice—you’re setting the stage for a lasting masterpiece that weathers the test of time.