When choosing between tung and linseed oil for hand-rubbed finishes, you’ll find tung oil offers a tougher, more water-resistant, and durable coating ideal for high-wear or outdoor projects. Linseed oil is easier to apply and dries faster but isn’t as durable or water-resistant, so you may need to reapply more often. Both oils require proper application and drying times—tung oil can take 24-48 hours between coats, while linseed dries in about 24 hours. Learning more will help you get the best results.

Key Takeaways

- Tung oil forms a tougher, water-resistant finish suitable for outdoor and high-wear projects, unlike linseed oil.

- Tung oil typically dries in 24-48 hours between coats, with full curing taking days to weeks, while linseed oil dries faster, in about 24 hours.

- Linseed oil is easier to apply but less durable and water-resistant than tung oil, requiring more frequent reapplications.

- Properly applying thin coats and wiping away excess enhances penetration, durability, and prevents tackiness.

- Patience with drying and curing times ensures a long-lasting, smooth, and attractive hand-rubbed oil finish.

Hand-rubbed oil finishes offer a simple yet effective way to enhance the beauty and durability of wood surfaces. When you choose between tung oil and linseed oil, understanding their application techniques and durability considerations is essential to achieving a long-lasting, attractive finish. Both oils have unique properties that influence how you apply them and how well they protect your wood over time.

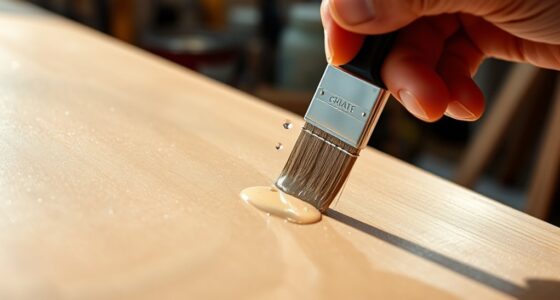

Application techniques for hand-rubbed oil finishes are straightforward but require attention to detail. Start by ensuring your wood surface is clean, dry, and smooth. Using a clean cloth or applicator, apply a generous amount of oil, working it into the grain with circular motions. For tung oil, it’s best to apply thin coats, allowing each to penetrate deeply into the wood before adding another. Linseed oil, particularly boiled linseed oil, can be applied more liberally, but you should still avoid excess buildup that can lead to a sticky or uneven finish. After application, let the oil sit for around 15-20 minutes, then wipe away any excess to prevent a tacky surface. Repeat this process with multiple coats, allowing adequate drying time between layers. Proper application guarantees the oil penetrates deeply, creating a durable and attractive finish that enhances the wood’s natural beauty. Monitoring drying times closely is crucial to avoid issues like tackiness or uneven curing.

Apply thin coats, wipe excess, and repeat for a durable, natural-looking wood finish.

Durability considerations play a significant role in your choice between tung and linseed oils. Tung oil is renowned for its superior water resistance and hardness once cured. It forms a tough, protective film that resists scratches and moisture, making it ideal for furniture, tabletops, or outdoor projects. Linseed oil, especially boiled linseed oil, offers decent protection but generally isn’t as water-resistant or hard as tung oil. Over time, linseed oil finishes may require reapplication to maintain their protective qualities. When considering durability, you should also factor in how well the finish will stand up to daily wear and environmental exposure. Tung oil, with its robust film-forming properties, tends to last longer and resist elements better, though it takes longer to dry and cure completely. Linseed oil, while easier to work with initially, may need more frequent touch-ups and reapplications to keep your wood protected.

Drying times also influence your application schedule. Tung oil can take anywhere from 24 to 48 hours to dry between coats, and full curing might take several days to weeks, depending on conditions. Linseed oil dries faster, often within 24 hours, but curing fully can take a week or more. Patience with drying and curing ensures your finish develops its maximum durability and aesthetic appeal. By understanding these application techniques and durability considerations, you can confidently select and apply the right hand-rubbed oil finish for your project, ensuring a beautiful, lasting result.

Frequently Asked Questions

Can Tung Oil Be Used Indoors Safely?

Yes, you can use tung oil indoors safely, but you should consider indoor safety and oil VOCs. Look for pure, food-grade tung oil with low VOC content to minimize fumes. Make certain proper ventilation during application and drying. Once cured, tung oil creates a safe, water-resistant finish suitable for indoor furniture and surfaces. Always follow manufacturer instructions to reduce any potential health risks associated with VOC emissions.

How Do Humidity Levels Affect Drying Times?

Humidity levels considerably impact drying times because moisture affects how quickly oils cure. When humidity is high, the moisture impact causes drying variability, making the finish take longer to set. Conversely, low humidity speeds up drying, but it can also lead to uneven curing or cracking. To get the best results, monitor humidity and allow extra time in damp conditions, ensuring your oil finish dries thoroughly and evenly.

Are There Eco-Friendly Options for Hand-Rubbed Oils?

Yes, you can choose eco-friendly options for hand-rubbed oils. Natural alternatives like walnut oil, jojoba oil, or mineral oil are biodegradable and safer for the environment. These options often have lower VOC emissions and come from renewable sources. By selecting biodegradable options, you diminish your impact on nature while achieving a beautiful finish. Always check product labels to ensure they’re truly eco-friendly and suitable for your project.

What Are the Best Cleaning Methods for Oil Finishes?

To clean oil finishes, you should use gentle cleaning solutions like a mixture of mild soap and water. Avoid harsh chemicals that can damage the finish. Regular maintenance procedures include wiping with a soft cloth and avoiding excess water. For stubborn spots, lightly buff with a soft cloth dampened with mineral spirits. This keeps your finish looking fresh and protected, ensuring longevity and beauty.

How Long Do Hand-Rubbed Oil Finishes Last?

You can expect your hand-rubbed oil finish to last years with proper care. Think of it as a living surface that ages gracefully, showing character over time. To maximize oil longevity, regularly clean with gentle methods and reapply oil as needed. Maintenance tips, like avoiding harsh chemicals and protecting from moisture, help your finish stay vibrant longer. With attentive upkeep, your finish maintains its beauty for many years.

Conclusion

Choosing between tung and linseed oil finishes isn’t just about drying times—it’s about connection. As you apply each layer, you realize that patience and care mirror life’s quiet moments of growth. Sometimes, the best finish isn’t just about protection but about the journey you take with your craft. In the end, whether tung or linseed, your touch becomes part of the wood’s story, reminding you that beauty often comes from the time you invest.