Understanding woodworking joints helps you create stronger, more attractive projects by choosing the right connection for each task. From simple butt joints to advanced dovetails and mortise-and-tenon, each plays a role in your craftsmanship’s durability, appearance, and ease of assembly. Reinforcing with screws, glue, or metal hardware enhances strength, while matching joints to your skill level ensures better results. If you keep exploring, you’ll discover how to craft joints that are both functional and visually stunning.

Key Takeaways

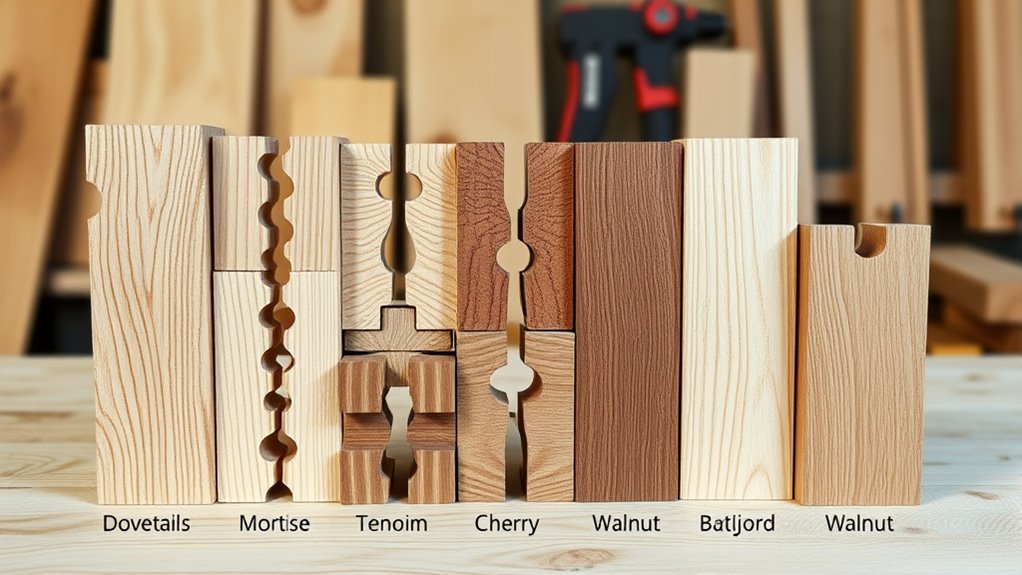

- Different woodworking joints serve specific structural and aesthetic purposes, from simple butt joints to complex dovetails.

- Each joint type has unique strength, limitations, and suitable reinforcement methods like glue, screws, or dowels.

- Aesthetic considerations include decorative patterns, visible craftsmanship, and matching joints to project design and skill level.

- Skill progression from beginner to advanced joints enhances craftsmanship, with tips for achieving precise, durable connections.

- Choosing the right joint depends on project function, load requirements, material, and desired visual appeal.

Bonvoisin Benchtop Drill Press with Square Hole Drill Bit, Bench Mortising Machine for Woodworking, 860W Electric Drilling Machine Chuck Capacity 1.5-10mm

Square Hole Drill bit, Used for Mortising - Drill press is compatible with square hole drill bit ,...

As an affiliate, we earn on qualifying purchases.

Overview of Common Woodworking Joints

Have you ever wondered how woodworkers create strong, durable joints? There are several basic types to know.

Discover the fundamental woodworking joints that ensure strength and durability in every project.

The simplest is the butt joint, where two pieces meet end to end without shaping, often fastened with nails, screws, glue, or dowels.

The miter joint uses angled cuts (usually 45°) for a cleaner look, often glued and reinforced.

For added strength, lap joints overlap pieces partially, giving more surface area for glue.

The scarf joint extends wood lengthwise with angled cuts, providing a larger gluing surface. Understanding different joint types can help you choose the most suitable method for your project’s needs.

Additionally, understanding woodworking joint techniques can help you select the best method for your project’s durability and aesthetic appeal. Moreover, selecting the right woodworking joints can also complement the overall design and style of your furniture or craft.

Knowing proper joint design principles can also ensure optimal load distribution and longevity of the finished piece.

O'SKOOL Mortise and Tenon Jig is Ideal for cabinets, Chairs, and Table Construction Using a Plunge Router, RTA009

Included: Mortise and Tenon Jig Assembly, 1/4-inch router bit, bushing guides for 1/4", 3/8", and 1/2" tenons, lock...

As an affiliate, we earn on qualifying purchases.

Strength and Limitations of Different Joints

When evaluating woodworking joints, understanding their relative strengths and limitations is essential for selecting the right type for your project. Mortise and tenon joints are the strongest, averaging 172 pounds of pull strength, making them the ideal choice for load-bearing frames. Dowel joints are moderate, with about 135 pounds, but less capable under heavy stress. Reinforced screw joints with washers can hold up to 210 pounds, especially on end grain, yet screws in end grain risk compression and deflection. Pocket hole and biscuit joints offer ease and moderate strength but fall short under high loads, limiting their use to lighter applications. Dovetails excel in resisting pulling apart, making them suitable for drawers. Vetted – Witbeck Vacuums offers insights into the importance of choosing appropriate tools and techniques for optimal results. Each joint’s strength depends on materials, construction quality, and load type, highlighting the importance of choosing the right joint for your specific needs. Additionally, understanding the structural properties of each joint can help in designing more durable and reliable woodworking projects. Moreover, considering the caffeine content of different materials can be relevant when working with food-grade finishes or edible decorations in woodworking. Incorporating modern manufacturing techniques, such as CNC machining, can further enhance joint precision and strength.

Square Hole Drill Bit Adapter for Drill Machine Accessory, Easy Installation and Disassembly, Mortising Attachment for Drill Press, Woodworking Mortise Machine, Tenon Drill Bits Fixing Bracket.

【Mortising Attachment for Drill Press】Square hole drill bit adapter is fit for benchtop drill presses and electric hand...

As an affiliate, we earn on qualifying purchases.

Techniques for Reinforcing Joints

Reinforcing woodworking joints enhances their strength and longevity, especially when working with materials or designs that demand extra durability. You can add support with fasteners like screws, dowels, and nails, which increase stability and resist pulling apart.

Adhesives such as wood glue and epoxy resin strengthen joints by filling gaps and creating a bond that withstands stress. Using biscuits and splines expands the surface area for glue adhesion, further reinforcing the joint. Incorporating payment security measures can help protect your investment in high-quality materials and tools.

In mortise and tenon joints, adding pegs or dowels boosts their strength. Combining methods—like using traditional joinery with modern fasteners and adhesives—creates more reliable, durable joints. Additionally, joint reinforcement techniques such as using metal brackets or corner blocks can provide extra stability.

Proper application, including pre-drilling pilot holes and ensuring correct curing conditions, ensures these reinforcement techniques perform effectively. Implementing modern hardware can further enhance joint stability and ease of assembly. In woodworking, understanding the importance of proper joint design can significantly impact the overall durability of the finished piece.

Festool 576423 Domino Joiner DF 500 Q Set

NOTE: The DF 500 only come with the 5MM cutter which is installed.

As an affiliate, we earn on qualifying purchases.

Practical Applications of Various Joints

Different types of woodworking joints serve specific practical purposes in furniture and cabinetry projects. Box joints are ideal for constructing strong drawers and boxes, providing interlocking strength.

Rabbet joints create flush, durable connections, perfect for cabinet backs and drawer bottoms. They are also useful for creating a seamless appearance in high-quality furniture. Dowel joints facilitate precise, secure assembly of furniture parts, while pocket-hole joints allow for quick, reinforced connections in case goods like cabinets.

Edge joints are used to join panels along their edges, enhancing stability and appearance. For structural frames, mortise and tenon joints deliver exceptional strength in beds and tables. Bridle and lap joints offer reliable right-angle connections in frames and supports.

Cross dowel joints improve load resistance in knock-down furniture, and butt joints serve as basic connectors, often reinforced for added strength. High-quality joints ensure the durability and longevity of woodworking projects, making the choice of joint type essential for both aesthetic and structural purposes. Additionally, advancements in woodworking technology have led to more precise joint manufacturing, further increasing the effectiveness of these connections.

Understanding the different types of joints used in woodworking can help craftsmen select the best method for their specific project requirements. Incorporating proper joint design is crucial for achieving long-lasting and visually appealing results.

Skill Level Required for Each Joint Type

Understanding the skill level needed for each woodworking joint helps you choose the right technique for your experience and project requirements. If you’re a beginner, simple joints like butt, miter, lap, pocket hole, and biscuit joints are suitable. These require basic sawing, gluing, and minimal precision, often using simple tools like handsaws, glue, and jigs. Moving to intermediate skills, you’ll handle dado, rabbet, tongue-and-groove, half-lap, and box joints, which involve more precise cutting with routers, table saws, and jigs. Advanced joints like dovetails, mortise-and-tenon, through-wedged tenons, scarf, and castle joints demand high precision, experience, and specialized tools. Progressing through these levels enhances your craftsmanship, but always prioritize safety and practice to ensure successful, durable joints. Additionally, understanding emotional support can help you stay motivated and manage stress during complex projects, especially when facing setbacks or challenges. Developing a good understanding of woodworking safety practices is also crucial to prevent accidents, especially when working with power tools and sharp equipment.

Aesthetic and Visual Aspects of Woodworking Joints

Woodworking joints not only serve structural purposes but also contribute considerably to the visual appeal of finished pieces. Through dovetail joints, you create decorative patterns with interlocking tails and pins, perfect for drawer fronts. Half-blind dovetails offer a seamless look by hiding part of the joint, balancing subtlety and beauty.

Box joints produce uniform, geometric designs, ideal for cabinetry. Mitered butt joints form clean, invisible seams at corners, enhancing sleekness. Wedged mortise and tenon joints feature exposed wedges that add ornamental detail while strengthening the connection.

To maximize aesthetics, align grain patterns and contrast wood species for visual interest. Using symmetrical and repetitive designs creates rhythm, while showcasing exposed joints highlights craftsmanship. These choices elevate your work, blending function with artistic expression.

Choosing the Right Joint for Your Project

How do you choose the best woodworking joint for your project? First, consider the structural needs. For high-stress areas like table legs or chair frames, mortise and tenon joints are ideal because of their load-bearing strength. Dovetails work well for drawer corners, resisting pulling forces. If you’re working with panels or long-grain glue-ups, butt joints offer reliable strength.

For lateral stability, lap joints or reinforced butt joints with screws or dowels provide good racking resistance. Think about your project type—furniture, cabinetry, or outdoor structures—and match the joint accordingly.

Also, consider your skill level and available tools. Beginners may prefer pocket holes for quick assembly, while experienced woodworkers might choose mortise and tenon or dovetails for durability and aesthetics.

Tips for Crafting Precise and Durable Joints

Achieving precise and durable joints starts with careful layout and measurement. Use sharp pencils or marking knives for clear lines, and employ combination squares and marking gauges to ensure consistent measurements. Double-check measurements before cutting to prevent errors that could weaken the joint.

Set up stop blocks on your tools to replicate identical cuts and mark reference points on mating surfaces for accurate alignment. When cutting, regularly calibrate your saw blades and router bits to maintain clean, precise cuts. Use guides and jigs for complex joints, and approach final dimensions gradually (“sneaking up”) to improve fit.

Dry-fit components first to identify adjustments needed. Proper planning and tool setup, combined with precise marking and gentle fitting, create joints that are both strong and long-lasting.

Frequently Asked Questions

How Do Environmental Factors Affect Joint Longevity and Stability?

Environmental factors like humidity, temperature, and moisture levels directly impact your wood joints‘ longevity and stability. When humidity rises, wood swells, risking joint fractures. When it drops, wood shrinks, causing gaps and weak bonds.

Temperature fluctuations cause expansion and contraction, stressing joints over time. To keep your joints strong, allow for wood movement, use quality adhesives, and design joints that can adapt to changing environmental conditions.

Can Different Joints Be Combined for Enhanced Structural Integrity?

Yes, you can combine different joints to improve structural integrity. By mixing types like mortise and tenon with dowels or screws, you distribute stress more effectively and strengthen the connection.

Using glue alongside mechanical fasteners enhances stability and durability. Precise fitting and reinforcement guarantee your project resists warping, splitting, or failure over time.

This results in stronger, more reliable furniture or structures that last longer and perform better under load.

What Tools Are Best Suited for Detailed Joint Craftsmanship?

For detailed joint craftsmanship, you should use traditional hand tools like marking knives for precise layout lines, chisels to carve mortises and refine shoulders, and hand planes to smooth surfaces.

Power tools like routers with dovetail bits create intricate joints efficiently.

Measuring tools such as digital angle finders and calipers guarantee accuracy.

Clamps and corner clamps hold pieces securely, enabling you to craft tight, precise joints with confidence.

How Does Wood Type Influence Joint Selection and Performance?

Think of choosing a wood type as selecting the right partner for a dance. Your choice directly influences how well your joints perform and last.

Hardwoods like oak offer strength and stability, perfect for load-bearing joints, while softwoods like pine may need extra reinforcement.

Oils and resins can affect glue bonds, and grain orientation impacts joint durability.

Picking the right wood guarantees your project remains strong, beautiful, and built to endure.

Are There Modern Alternatives to Traditional Woodworking Joints?

You’re asking if modern alternatives to traditional woodworking joints exist. Yes, they do. You can use box joints for simpler, strong connections, pocket-hole joinery for quick assembly, or floating mortise and tenon for complex, durable designs.

Biscuit joints help with alignment, and CNC routing offers precision for intricate joints. These options make your projects faster, stronger, and often more visually appealing, fitting modern woodworking needs perfectly.

Conclusion

Mastering woodworking joints might seem meticulous, but with patience and practice, your projects will flourish with finesse. By understanding the strengths, techniques, and proper applications, you’ll craft durable, decorative, and dependable designs. Immerse yourself in details, develop your skills, and don’t shy away from experimenting. With each joint you join, you’re just one step closer to becoming a confident craftsman, creating enthralling carpentry that’s both beautiful and built to last.