To keep your power tools in top shape, regularly remove dust from vents, switches, and moving parts using compressed air or a soft brush. Proper dust removal prevents overheating and improves performance. Lubricate gears and bearings as recommended by the manufacturer to reduce friction and wear, while avoiding over-lubrication that can trap dirt. Also, inspect cords and batteries for damage, storing and maintaining them properly. Continuing further will help you master all essential care practices to extend your tools’ lifespan.

Key Takeaways

- Regularly clean vents, switches, and moving parts with compressed air or a soft brush to prevent dust buildup.

- Use manufacturer-recommended lubricants on gears and bearings to ensure smooth operation and reduce wear.

- Avoid forcing dust into sensitive components and focus cleaning around vents, brushes, and airflow pathways.

- Inspect and replace damaged cords promptly; store batteries properly in a cool, dry place with 40-60% charge.

- Proper dust removal and lubrication extend tool lifespan, improve performance, and prevent overheating or early failure.

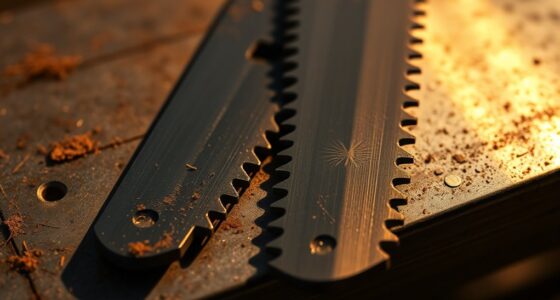

Proper care of your power tools is essential to make certain they perform reliably and last longer. Dust removal and lubrication are key components of maintenance that keep your tools in top shape. When it comes to dust, it’s crucial to regularly clear out debris that can accumulate inside vents, motor housings, and moving parts. Dust can cause overheating, impair performance, and even lead to early failure. Use compressed air or a soft brush to gently remove dust without forcing it further into sensitive components. Pay close attention to areas around switches, vents, and brushes, as buildup in these spots can reduce airflow and cooling efficiency. Additionally, maintaining proper airflow around the tool can significantly improve its cooling and overall performance.

Regularly clean vents and motor housings to prevent overheating and ensure optimal power tool performance.

Lubrication plays an equally vital role in maintaining your tools’ longevity. Many power tools have moving parts that require periodic oiling to reduce friction and prevent wear. Check your manufacturer’s recommendations for the proper type of lubricant and the frequency of application. Applying lubricant to gears, bearings, and other moving parts can significantly extend their lifespan, ensuring smoother operation and less strain on the motor. Remember, over-lubrication can attract dust and dirt, so use just enough to coat the parts without excess.

Another aspect of power tool care involves cord maintenance, especially if you’re using corded models. Regularly inspect your power cords for cuts, frays, or exposed wires. Damaged cords pose safety hazards and can cause power interruptions, which may damage the tool or lead to accidents. When you notice any damage, replace the cord immediately or repair it with appropriate connectors. Proper cord management also includes avoiding sharp bends or pinching, which can weaken the insulation over time. Keeping cords neat and untangled not only prolongs their life but also reduces trip hazards and ensures safe operation.

For battery-powered tools, proper battery storage is crucial. When not in use, store batteries in a cool, dry place away from direct sunlight or heat sources, as extreme temperatures can degrade battery life. Avoid leaving batteries in the tool itself for extended periods, especially if you won’t be using the tool for a while. Instead, remove the battery and store it separately, ideally at around 40-60% charge to maintain optimal capacity. Regularly check batteries for signs of swelling, corrosion, or reduced run time. Proper storage and maintenance of batteries help prevent leaks and ensure they deliver consistent power when you need it. To maximize battery lifespan, consider using appropriate storage techniques recommended by the manufacturer.

Frequently Asked Questions

How Often Should I Replace the Lubricant in My Power Tools?

You should replace the lubricant in your power tools based on the lubricant’s lifespan and your maintenance schedule. Typically, it’s best to check every few months, especially if you use the tools frequently. If you notice increased friction or noise, it’s time for fresh lubricant. Regularly inspecting and maintaining your tools guarantees smooth operation and prolongs their lifespan, keeping your equipment in top condition.

Can I Use Household Cleaning Products to Remove Dust?

Imagine your power tool as a race car engine, delicate and precise. Using household cleaners for dust removal isn’t recommended because they can leave residues or damage parts. Stick to proper dust removal methods like compressed air or soft brushes. Household cleaners aren’t designed for power tools, and they might harm internal components, reducing your tool’s lifespan. Keep it clean with the right approach for peak performance.

What Types of Lubricants Are Best for Different Power Tool Parts?

You should choose lubricants compatible with your power tool parts, like lightweight oils for motors and grease for gears. Always check the manufacturer’s recommendations. Use proper lubrication application techniques, such as applying a thin layer and avoiding excess, to prevent buildup. This guarantees smooth operation and prolongs your tool’s lifespan. Regularly inspecting and maintaining lubrication helps prevent wear and keeps your tools running efficiently.

Is It Safe to Clean Dust With Compressed Air?

Yes, using compressed air for dust removal is generally safe if you follow proper compressed air safety guidelines. Make sure to use short bursts to prevent moisture buildup and avoid directing air into sensitive parts. Use proper dust removal techniques by keeping the nozzle a safe distance from the tool. Always wear eye protection and work in a well-ventilated area to protect yourself from dust and debris.

How Do I Prevent Dust Buildup During Extended Use?

Think of your power tool as a well-tuned orchestra; to keep it harmonious, you need dust prevention and airflow optimization. During extended use, regularly pause to clean vents with compressed air and guarantee filters are clear. Use dust collection accessories if available. This proactive approach minimizes buildup, maintains performance, and extends your tool’s life, just like a conductor maintaining the symphony’s clarity and rhythm.

Conclusion

By regularly removing dust and applying proper lubrication, you keep your power tools running smoothly—like a well-tuned engine. Think of your tools as your trusted partners; neglecting their care can lead to breakdowns, but with consistent maintenance, they’ll perform like a finely crafted machine. Take these simple steps seriously, and your tools will serve you reliably for years to come. Caring for them is like tending a garden—you reap the benefits with every use.