To check if your corner is square without a traditional square, you can use the 3-4-5 method: measure 3 units along one side, 4 units along the adjacent, then measure the diagonal between these points. If it equals 5 units, your corner is square. Alternatively, measure both diagonals of the square or rectangle; if they match, the shape is true. Keep exploring these simple techniques to guarantee perfect accuracy in your projects.

Key Takeaways

- Use the 3-4-5 method by measuring 3 units along one side, 4 units along the adjacent, then check if the diagonal measures 5 units to verify squareness.

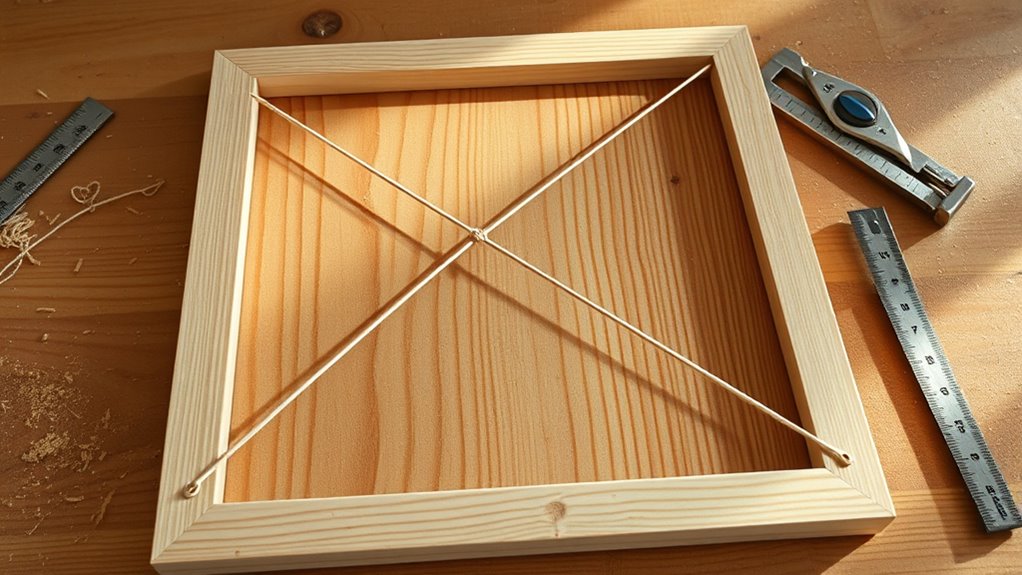

- Measure both diagonals; if they are equal, the corner is square, confirming proper alignment without a traditional square.

- The technique relies on the Pythagorean theorem: a right angle exists if the diagonal matches the square root of the sum of the squares of the sides.

- Adjust framing or cuts if diagonal measurements do not match or the 3-4-5 ratio isn’t achieved, ensuring accurate right angles.

- This method is practical, quick, and requires only a measuring tape, making it ideal when a specialized square isn’t available.

Ensuring a corner is perfectly square is essential in many construction and woodworking projects, but sometimes you don’t have a specialized square handy. When that happens, you can still verify your angles and ensure your corners are true by using simple methods like the 3-4-5 rule and diagonal measurement. These techniques rely on basic geometry and are highly effective for angle verification, especially when you need quick, reliable results.

Verify square corners easily with the 3-4-5 rule and diagonal checks—simple geometry for quick, reliable results.

The 3-4-5 method is a classic way to check right angles. To do this, you measure and mark lengths of three, four, and five units along the sides of your corner. For example, if you’re working with inches, measure 3 inches along one side, 4 inches along the adjacent side, and then measure the diagonal between these two points. If the diagonal measures exactly 5 inches, your corner is perfectly square. This method works because of the Pythagorean theorem, which states that in a right-angled triangle, the square of the hypotenuse (the diagonal) equals the sum of the squares of the other two sides. When your diagonal measurement matches the calculated value, you’ve verified the angle’s correctness without a square. This technique is especially useful when working with larger pieces or in situations where a square isn’t easily accessible.

Diagonal measurement also plays a vital role in confirming your project stays true to square. Instead of relying solely on angles, you can measure diagonals across rectangular or square sections. When the diagonals are equal, it indicates the shape is square or rectangular, and your corners are properly aligned. To do this, measure from one corner to the opposite corner, then repeat the measurement at the other diagonal. If both measurements match, your shape is accurate, and your corners are at right angles. If there’s a discrepancy, adjust your framing or cuts until the diagonals match. This approach helps prevent skewing and ensures your entire structure remains aligned, especially in larger frames or when assembling panels. Additionally, understanding how market volatility can impact precious metals investments like gold can help you make more informed decisions about your project investments.

Using these methods allows you to perform reliable angle verification and diagonal measurement without specialized tools. They’re straightforward, quick, and based on established geometric principles. Whether you’re checking a corner, verifying a cut, or ensuring your frame remains square, these techniques save time and eliminate the need for a traditional square. They also help you develop a better understanding of geometric relationships, which is invaluable in woodworking and construction. With a little practice, you’ll find these methods become second nature, giving you confidence that your projects stay true, even when a square isn’t immediately at hand.

Frequently Asked Questions

Can the 3-4-5 Method Be Used on Irregular Shapes?

Yes, you can use the 3-4-5 method for triangle validation on irregular shapes, but with limitations. It’s most effective for verifying right angles in triangles, not complex, irregular shapes. Shape irregularities may hinder perfect results, so this method works best on simple triangles or when approximations are acceptable. Keep in mind, for more complex shapes, other measurements or tools might be necessary to guarantee accuracy.

What Tools Are Best for Measuring Diagonals Accurately?

Measuring diagonals is like traversing a tightrope — precision is key. You’ll find laser distance meters invaluable for their accuracy and ease, especially over long spans. Digital calipers are perfect for smaller, detailed measurements, giving you tight control. These tools help you avoid guesswork, ensuring your angles are true and your shapes are perfect. Using the right tools makes the difference between a shaky walk and a confident step.

How Does the 3-4-5 Method Compare to Digital Tools?

You find the 3-4-5 method more straightforward and reliable than digital tools for checking square. While digital measurement tools offer high digital precision, they can be affected by calibration issues or battery life. The 3-4-5 technique provides a quick, manual way to verify right angles without relying on batteries or electronics, making it especially useful in fieldwork or when digital tools are unavailable.

Can Checking Diagonals Ensure Perfect Right Angles?

Checking diagonals can help verify right angles, but it’s not foolproof for perfect accuracy. Diagonal verification involves measuring the distances across opposite corners; if they’re equal, your angles are likely correct. However, slight measurement errors can affect angle accuracy. For precise results, combine diagonal checks with other methods like the 3-4-5 technique. This way, you make certain your corners are truly square and your project remains accurate.

Are There Alternative Methods for Checking Square Without a Square?

Yes, you can use alternative techniques for checking square without a square through visual verification and simple tools. For example, you can create a DIY square using a piece of cardboard or a straight edge and check for consistent gaps along the edges. Additionally, measuring and comparing angles with a combination square or using the 3-4-5 method helps confirm right angles, ensuring your project stays precise without a dedicated square.

Conclusion

Now that you’ve explored how the 3-4-5 triangle helps verify right angles without a square, you see that sometimes, the simplest tools are the most effective. By checking diagonals and using basic geometry, you can confidently guarantee your corners are true. Remember, it’s often the little tricks that save the day—don’t let this knowledge go to waste. Keep these methods in your toolkit; they’re worth their weight in gold when precision matters most.