Eccentric and multi-axis turning open up exciting design possibilities by enabling you to create complex, unique shapes beyond traditional methods. You can experiment with off-center features, curved surfaces, and intricate geometries that capture artistic flair and technical precision. Selecting the right materials and specialized tooling makes these designs attainable, while proper setups guarantee quality results. Keep exploring to discover how to push your creative boundaries even further with these advanced machining techniques.

Key Takeaways

- Utilize multi-axis capable tools and pivoting heads to create complex, eccentric geometries with precision.

- Select durable materials like titanium or hardened steel to withstand multi-directional cuts and offsets.

- Use CAD/CAM simulation to plan tool paths and optimize angles for intricate, multi-axis designs.

- Design custom fixtures or modular setups to securely hold parts during eccentric and multi-axis machining.

- Incorporate aesthetic elements by combining materials and finishes, enabled by strategic tooling and material choices.

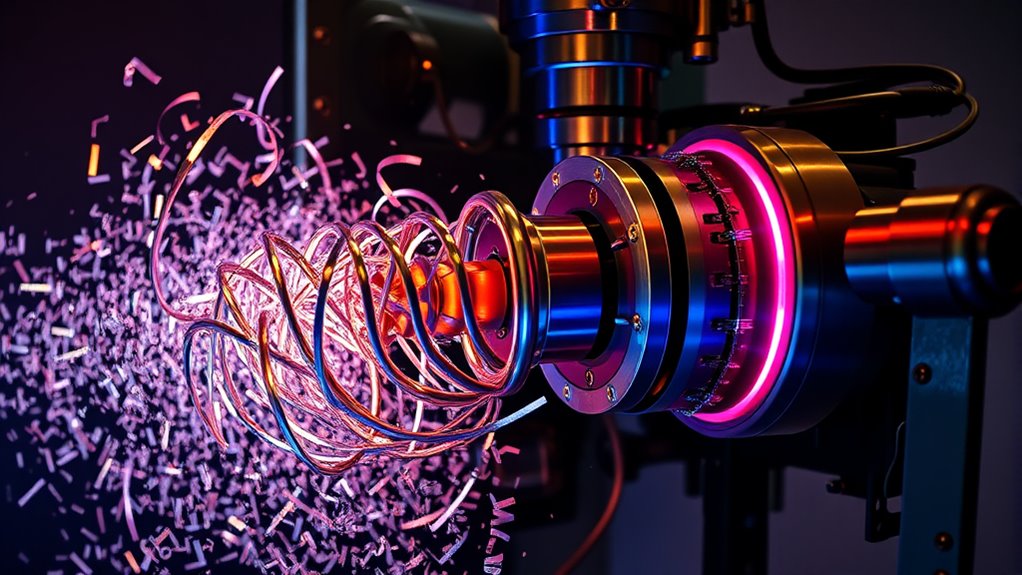

Eccentric and multi-axis turning open up innovative possibilities for creating complex, dynamic shapes that are impossible with traditional methods. When you explore these techniques, your choice of material plays a critical role. Not all materials respond equally to the stresses and movements involved in eccentric or multi-axis operations. For intricate, precision work, you might opt for durable metals like titanium or hardened steels, which withstand tool wear and maintain tight tolerances. For lighter, decorative pieces, plastics or aluminum can be easier to machine and reduce tool fatigue. Your material selection influences not only the final aesthetic but also the feasibility of executing complex geometries. It’s imperative to match the material’s properties with your intended design, guaranteeing it can handle the eccentric offsets and multi-directional cuts without cracking or deforming. Additionally, understanding the material properties can help you select the most suitable options for your specific machining requirements.

Choosing the right material is crucial for successful eccentric and multi-axis turning projects.

Tooling strategies are equally essential to the success of your project. When working with eccentric or multi-axis setups, traditional tooling can fall short, so you need to adapt your approach. Consider using multi-axis capable tools or specialized cutting heads that can pivot or tilt during machining. These tools allow you to achieve smooth, continuous curves and intricate features that follow complex spatial paths. Additionally, you should plan your tooling paths carefully—using CAD/CAM software to simulate movements and optimize cutting angles. Proper tooling strategies also involve selecting inserts and cutters with sharp edges and appropriate geometries to handle the unique forces involved. This reduces chatter and vibration, which are more common in multi-axis operations, and results in cleaner, more precise finishes.

Furthermore, your tooling setup must accommodate the eccentric or multi-axis machine’s capabilities. Clamping systems should be secure yet flexible enough to allow for the offsets and rotations necessary for complex shapes. Sometimes, custom fixtures or modular tooling arrangements are needed to maintain stability during multi-directional cuts. Don’t overlook the importance of consistent coolant application and chip removal; in complex machining, overheating or chip buildup can jeopardize your workpiece integrity.

In essence, mastering eccentric and multi-axis turning hinges on your ability to select the right materials and develop effective tooling strategies. These choices directly impact the quality, complexity, and feasibility of your designs. By thoughtfully pairing appropriate materials with adaptive tooling approaches, you empower yourself to push the boundaries of what’s possible, creating innovative, compelling shapes that stand out. Your attention to these foundational elements ensures your projects not only succeed technically but also achieve the artistic vision behind your complex geometries.

Frequently Asked Questions

What Materials Are Best Suited for Eccentric and Multi-Axis Turning?

For eccentric and multi-axis turning, you should choose materials that offer excellent machining flexibility and durability. Metals like aluminum, brass, and mild steel are ideal because they cut smoothly and reduce tool wear. Additionally, plastics such as ABS or Delrin work well for complex shapes due to their ease of machining. Selecting the right material guarantees precision, minimizes vibrations, and enhances the overall quality of your turning projects.

How Do Tool Wear and Maintenance Impact Complex Turning Operations?

Think of your tool as a warrior on a demanding quest; wear and tear are the relentless storms it faces. You’ll want high-quality tool material to withstand the journey, and smart lubrication strategies to reduce friction and heat. Regular maintenance acts like armor repairs, keeping your tool sharp and precise. When you manage wear and maintenance well, your complex turning operations stay smooth, accurate, and efficient, even through the most challenging twists and turns.

Can Eccentric and Multi-Axis Turning Be Automated Effectively?

Yes, you can automate eccentric and multi-axis turning effectively. By leveraging advanced CNC machines and robotics, you improve automation efficiency, reducing manual intervention. However, you need to manage programming complexity carefully; intricate tool paths and setups demand sophisticated software and skilled operators. With proper planning and technology, automation enhances precision, consistency, and productivity, making complex turning operations more streamlined and cost-effective for your manufacturing processes.

What Are the Safety Considerations for Advanced Turning Techniques?

When using advanced turning techniques, safety hinges on maintaining machine stability and thorough operator training. For example, a shop improved safety by upgrading fixtures to prevent tool ejection during eccentric turning. Always guarantee your machine is well-maintained, with guards in place, and that operators understand the risks and proper procedures. Regular training keeps everyone alert, reducing accidents and ensuring safe, precise results in complex turning operations.

How Does Cost Vary Between Traditional and Eccentric/Multi-Axis Turning?

You’ll find that eccentric and multi-axis turning generally increase costs due to more complex cost analysis and higher tooling expenses. These techniques often require specialized tools and equipment, which drive up initial investments. Additionally, the increased complexity may lead to longer setup times and higher operational costs. While they offer advanced design possibilities, expect your overall expenses to be higher compared to traditional turning methods.

Conclusion

By exploring eccentric and multi-axis turning, you open a world of endless creativity and precision. These techniques transform simple materials into stunning masterpieces, making your work stand out like a blazing comet streaking across the night sky. With imagination and skill, you can push the boundaries of traditional machining, creating intricate designs that seem almost alive. Embrace these ideas, and watch your craftsmanship reach heights so extraordinary, they’ll leave everyone in awe.