To perform the ten-second test, hold the lumber and gently twist or bend it, feeling for stiffness or resistance. Inspect the grain pattern for irregularities, tight or uneven areas, and shiny patches indicating rapid drying or internal stress. Look for surface cracks, dull or darker spots, and uneven textures that can signal case-hardening. mastering this quick check helps you identify problem wood quickly; continue further to learn more about detailed detection techniques.

Key Takeaways

- Gently twist or bend the lumber to assess stiffness and resistance within seconds.

- Look for irregular, uneven, or tight grain patterns indicating internal stress.

- Check for shiny, glassy patches or slick areas on the surface that suggest case-hardening.

- Scan for surface cracks, fissures, or irregularities that may signal internal brittleness.

- Observe color and texture uniformity; darker or shinier patches often point to rapid drying and potential flaws.

When you’re selecting lumber, a quick ten-second test can help you identify case-hardened wood—an issue that can compromise strength and durability. This simple check relies on your ability to perform a quick grain inspection and defect detection, enabling you to avoid materials that might cause problems down the line. Case-hardening occurs when the outer surface of the wood dries too quickly, trapping moisture inside and creating a hard, brittle shell. This makes the lumber more prone to cracking, splitting, or warping under stress. Recognizing these signs early is vital for ensuring your project’s longevity.

Perform a quick grain and defect check to avoid case-hardened, brittle lumber.

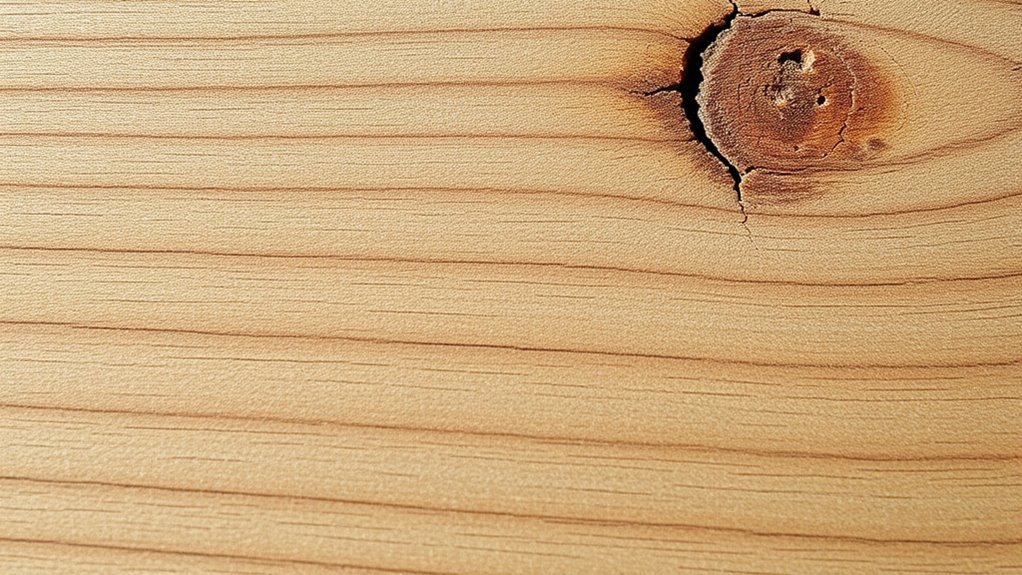

To perform the test, hold the piece of lumber in your hand, and give it a gentle twist or bend. If the wood feels unusually stiff or resistant, that’s a red flag. As you do this, pay close attention to the grain pattern. During grain inspection, look for irregularities like uneven grain, which can indicate internal stress or defects. If the grain appears tight or shows signs of a glassy, shiny surface, that often points to case-hardening. These areas tend to be denser and more brittle, which can limit the wood’s flexibility and strength.

Defect detection is key here. Case-hardened wood often exhibits surface cracks, shiny patches, or a slick feel when touched. These surface irregularities are signs that the outer layer has dried too rapidly, sealing moisture inside and creating internal tension. If you notice any cracking or shiny spots during your grain inspection, it’s best to steer clear. Such defects can weaken the overall structure, making the lumber less reliable for load-bearing applications or projects where durability matters.

In addition to feeling the wood, observe its appearance. Properly dried lumber should have a uniform color and texture. If parts of the surface look darker or shinier than others, it could indicate uneven drying or case-hardening. The quick test is not foolproof but provides a rapid, effective way to filter out compromised wood. It’s especially useful when sourcing lumber on-site or in a store where detailed analysis isn’t feasible. Being aware of drying processes and their impact on wood quality can help you select stronger, more durable materials for your projects.

Frequently Asked Questions

Can the Ten-Second Test Be Used on All Types of Wood?

You might wonder if the ten-second test works on all types of wood. While it’s useful for spotting case-hardened lumber, its effectiveness depends on factors like grain pattern and moisture content. Denser woods with tight grain patterns and high moisture content may not respond as clearly to the test. So, it’s best to take into account these characteristics before relying solely on the ten-second test for different wood types.

Does the Test Damage the Lumber?

Imagine pressing your hand gently on a sponge; it leaves a mark without damage. Similarly, the test doesn’t harm the wood. It’s quick because it considers wood density and moisture content, which influence how the wood reacts. You won’t cause any damage, even if you test multiple pieces. It’s like a gentle tap that reveals hidden strength without leaving a mark, ensuring your lumber stays pristine.

Are There Tools That Can Assist With the Test?

You can use tools like a moisture meter or a surface hardness tester to assess lumber quickly. These tools help you gauge moisture levels and surface hardness without damaging the wood. A moisture meter provides an accurate reading of internal moisture, while a hardness tester checks the surface’s resistance. Both are handy for ensuring your lumber isn’t case-hardened, saving you time and preventing costly mistakes during your project.

How Does Case-Hardening Affect Lumber Strength?

You might think surface discoloration affects lumber strength, but case-hardening actually reduces wood density near the surface, making it more brittle. This process creates a hardened outer layer that can crack or splinter under stress, decreasing overall strength. Visual cues like surface discoloration help you spot case-hardened wood early. Recognizing these signs guarantees you select lumber with peak strength, avoiding compromised pieces that could lead to structural issues.

What Are Common Signs of Case-Hardening Besides the Test?

You can identify case-hardened lumber by looking for moisture indicators like uneven moisture content and surface discoloration. These signs often appear as darkened or stained areas on the surface, indicating the outer layer has hardened while the core remains softer. Additionally, you might notice surface cracks or a rough texture, which suggest the wood has undergone case-hardening. Keep an eye out for these visual cues to spot affected lumber early.

Conclusion

Remember, spotting case-hardened lumber is like catching a sneaky flaw before it grows. I once inspected a batch, and in just ten seconds, I spotted a tiny, shiny spot—like a warning sign. That quick glance saved me from future headaches, proving this test’s power. Trust your eyes; with practice, you’ll spot trouble faster than a blink. It’s your secret weapon to ensure sturdy, reliable wood every time.