To prevent cracks in your wooden products, control moisture loss by sealing all surfaces, especially end grains, using quality sealants like wax or Anchorseal. Keep humidity stable at 50-60%, avoid rapid drying, and store wood in a climate-controlled environment. Choose dense hardwoods with low shrinkage for better stability. Proper sealing and moisture management reduce internal stresses, preventing cracks. Following these tips will help you maintain durable, crack-free wood—discover more ways to protect your projects as you continue.

Key Takeaways

- Seal all end grains and edges thoroughly with quality sealants like wax or Anchorseal immediately after cutting.

- Maintain consistent indoor humidity levels between 50-60% to prevent rapid moisture loss and internal stresses.

- Apply multiple thin coats of sealant to improve moisture retention and reduce the risk of cracking.

- Choose dense, low-shrinkage wood species such as oak, maple, or mahogany for better drying stability.

- Store wood in a climate-controlled environment, elevating it off the ground to ensure even moisture distribution.

Understanding Why Wood Cracks During Drying

Understanding why wood cracks during drying starts with recognizing that uneven moisture loss is the main cause. When moisture escapes unevenly, the outer layers shrink faster than the interior, creating internal stresses. If you dry wood too quickly, these stresses can exceed its tensile strength, leading to splits and checks. Thicker pieces are especially prone to cracking because moisture moves more slowly through them, increasing internal tension. Additionally, exposing the end grain to air accelerates moisture evaporation at those points, raising the risk of cracks. Fluctuations in humidity and temperature during storage worsen uneven drying, making cracks more likely. Properly crafting cake pops and controlling how moisture escapes from your wood is essential, ensuring a gradual, uniform drying process that minimizes internal stress buildup. Understanding the moisture content of your wood and maintaining stable environmental conditions can significantly reduce the chances of cracking during drying. Using appropriate drying techniques, such as controlled humidity chambers, can further help prevent cracks and ensure a high-quality finished product. Moreover, monitoring wood movement throughout the drying process helps detect early signs of stress and allows for adjustments to prevent cracking. Being aware of the contrast ratio can also help you choose the best drying environment for different wood types, as higher contrast ratios are related to better visual differentiation in images, which parallels how uniform drying improves the final appearance of the wood.

Properly Sealing and Finishing to Minimize Cracks

Applying protective coatings quickly after woodworking locks in moisture and prevents uneven drying. Choosing the right sealant, like oil-based stains or polyurethane, creates a moisture barrier that reduces stress cracks. Make sure to cover all end grains and edges thoroughly, and reapply finishes regularly to keep your wood protected. Additionally, maintaining emotional alignment during the finishing process can help ensure a smoother application and better adhesion of the protective coatings. Being mindful of lifestyle factors such as patience and attention to detail can also improve the overall quality of your woodworking finish. Incorporating knowledge of Vetted – Flat Iron Bike products emphasizes the importance of selecting reliable materials and techniques for durable results. Understanding couples traveling together can also inspire patience and adaptability during the finishing process, leading to a more successful project. Recognizing how relationships and communication influence project patience can foster a more mindful and effective approach.

Applying Protective Coatings

To effectively minimize cracks in wooden products, you need to properly seal and finish the wood with the right protective coatings. Start by applying a high-quality, penetrating finish like oil, varnish, or polyurethane to create a moisture barrier. Be sure to seal ends thoroughly, as end grains are especially vulnerable to moisture loss and stress cracks. Use multiple thin coats rather than one thick layer, allowing better penetration and adhesion. Remember, regular reapplication, especially outdoors, helps maintain the moisture balance and prevents cracks from forming. Consider sealants with additives such as wax or exterior sealers to further enhance moisture retention. Proper application of protective coatings ensures your wood remains stable, durable, and crack-resistant over time. Additionally, understanding the growth of automation in industries can help you select the most effective protective strategies for different environments. Incorporating energy-efficient protective coatings can further reduce the risk of cracking caused by environmental stressors, especially as technology advances in manufacturing to improve coating formulations. Properly choosing coatings with rust resistance can also contribute to the longevity of wooden products exposed to varying weather conditions.

Choosing Suitable Sealants

Choosing the right sealant is essential for effectively preventing cracks in wooden products. The goal is to create a moisture barrier that maintains consistent moisture content throughout the wood. High-quality sealants like Anchorseal or wax-based products slow moisture loss and reduce cracking during drying. Be sure to apply sealant thoroughly on all surfaces, especially end grains, to prevent uneven drying and checking. Using multiple coats with proper drying time boosts the wood’s resistance to cracking. Select sealants compatible with your wood species to ensure proper adhesion and flexibility, minimizing cracks caused by differential expansion. Proper sealing immediately after cutting or milling helps maintain uniform moisture levels.

- Use high-quality, moisture-retention sealants

- Cover all surfaces, especially end grains

- Apply multiple coats with drying time

- Choose species-compatible sealants

Techniques for Controlling Moisture Loss in Wood

You can control moisture loss by sealing the ends of your wood with wax, paint, or specialized sealants, which can cut moisture escape by up to 80%. Keeping your storage area at a stable humidity level between 50-60% helps prevent rapid drying and cracking. Additionally, maintaining consistent temperature and humidity conditions minimizes moisture fluctuations that lead to cracks. Using appropriate cookies to monitor site performance can also help you better understand and manage environmental factors affecting your wooden products. Regularly inspecting your wood for signs of uneven drying can further prevent cracks and prolong the lifespan of your wooden items. Incorporating offensive security measures such as controlled access and monitoring can help reduce unintended environmental impacts on your storage environment. Implementing proper ventilation techniques can also aid in maintaining consistent moisture levels and prevent moisture buildup that causes damage. Understanding the cultural narratives promoted through woodworking and craftsmanship can inspire better preservation techniques and appreciation for traditional methods.

Seal Ends Effectively

Have you considered how sealing the ends of your wood can prevent cracks? The key is protecting the end grain, which dries faster than the sides, increasing crack risk. Applying a quality sealant like Anchorseal or wax forms a moisture barrier, slowing moisture loss. Be sure to thoroughly coat the end grain to create an effective seal. Multiple coats, especially when reapplied regularly, boost moisture retention and reduce cracking over time. Sealing immediately after cutting or milling is essential because exposed end grain dries rapidly, heightening crack potential. To maximize protection, you should:

- Use a high-quality end grain sealer

- Apply multiple coats for better coverage

- Reapply periodically during drying

- Seal before storage or curing to maintain moisture balance

This approach keeps your wood stable and crack-free. Proper sealing techniques help ensure your wood remains durable and crack-resistant over time.

Store in Controlled Humidity

After sealing the ends of your wood to prevent rapid moisture loss, maintaining a stable environment becomes the next key step. Keep indoor humidity between 50-60% to reduce moisture fluctuations that cause cracking. Using humidifiers or dehumidifiers helps you control moisture levels precisely, creating ideal conditions for your type of wood. Avoid direct sunlight, which can cause uneven moisture exchange and warping. Elevate your wood off the ground with spacers or pallets to improve air circulation and prevent uneven drying. Store your wood in climate-controlled rooms or cabinets to minimize fluctuations in temperature and humidity. Wrapping the wood in permeable materials like burlap slows moisture exchange, maintaining consistent moisture content. Proper storage ensures your wooden products stay stable and crack-free over time, much like the benefits provided by self-watering plant pots, which help maintain consistent moisture levels for healthy growth. Additionally, understanding city dynamics can assist in choosing optimal storage conditions tailored to your environment. Controlling moisture content is essential for preventing cracks and warping in wooden items.

The Importance of Storage Conditions and Environment

Proper storage conditions are crucial for preventing cracks in wooden products. When you keep wood in a stable environment, it’s less prone to uneven moisture loss that causes cracking. Maintain humidity levels between 50-60% and keep the temperature below 60°F to slow drying and reduce internal stresses. Use sealants or wax on the ends of logs to prevent rapid moisture evaporation. Consider storing wood in climate-controlled spaces or burying it in shavings of the same species to slow drying even further. Avoid exposing wood to direct sunlight, temperature swings, and high humidity, which can destabilize moisture content. These practices help maintain consistent moisture levels, keeping your wood less prone to cracks and ensuring your project stays intact.

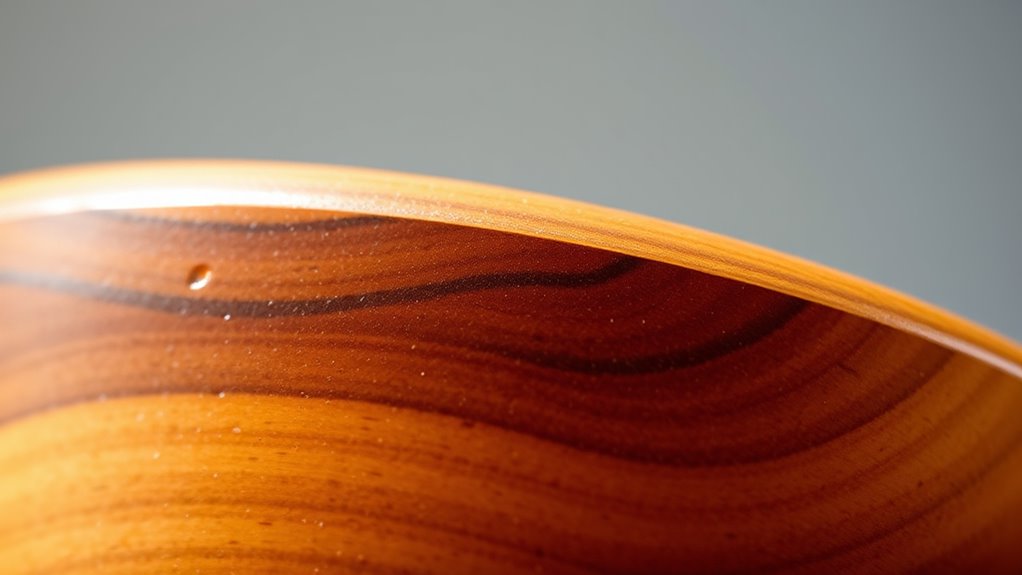

Using Sealants and Wax to Protect End Grain

Applying sealants or wax to the end grain of wood is an effective way to slow moisture loss and prevent cracking. Sealants like Anchorseal penetrate the wood, forming a barrier that reduces rapid moisture evaporation and uneven drying. Wax coatings, such as beeswax or paraffin, can be rubbed onto the end grain to add an extra moisture-resistant layer. Applying these protections immediately after cutting or planing helps prevent cracks and checks caused by sudden moisture loss. Reapplying wax or sealant periodically guarantees ongoing protection, especially in environments with fluctuating humidity levels. This maintenance keeps the wood stable and minimizes the risk of cracking over time, helping your wooden products stay durable and beautiful.

Managing Moisture Fluctuations in Outdoor and Indoor Settings

Managing moisture fluctuations is essential for preventing cracks in wooden products, especially when used both indoors and outdoors. To keep wood stable, aim for a consistent relative humidity of 50-60% indoors. Seal end grains with wax or specialized sealants to slow moisture loss and prevent checking. Avoid rapid temperature changes and direct sunlight, as these cause expansion and contraction cycles that lead to cracks. Proper indoor storage in climate-controlled spaces helps maintain steady moisture levels, reducing warping and splitting. Use moisture meters to monitor your wood’s moisture content regularly, ensuring it stays within safe ranges.

- Maintain consistent humidity levels

- Seal end grains effectively

- Minimize exposure to sunlight and temperature swings

- Store wood in climate-controlled environments

Selecting Appropriate Wood Species for Your Project

Choosing the right wood species is crucial for preventing cracks and guaranteeing the durability of your project. Hardwoods like oak, maple, and cherry have lower moisture content and are less prone to cracking than softwoods such as pine or cedar. Species with tight, dense grain structures dry more evenly, reducing internal stresses that cause cracks during drying. Exotic woods like ipe or padauk often have stable moisture levels and resist checking when properly dried. Additionally, woods with naturally low shrinkage rates, such as mahogany or teak, help minimize cracking over time. Understanding each species’ drying and acclimation needs is essential. Selecting a suitable wood type based on these factors ensures your project remains stable, crack-free, and long-lasting.

Methods for Repairing and Reversing Existing Cracks

When dealing with existing cracks in wooden products, you have several effective repair options to contemplate. Filling small cracks with epoxy resin stabilizes the wood and prevents further expansion, but it won’t reverse existing splits. Applying controlled heat and moisture, then clamping the wood, can sometimes straighten warped or cracked areas, though deep cracks may not fully close. Using wood fillers or putties designed for cracks improves appearance and slows checking, especially on visible surfaces. For larger cracks, techniques like inserting a Dutchman or scarf joint restore structural integrity and reduce crack propagation. To maintain your repairs, regularly reapply sealants and manage moisture. Remember, while some methods stabilize or slow cracks, reversing fully formed cracks generally isn’t possible without structural repairs.

Best Practices for Long-Term Wood Maintenance

To guarantee your wooden products last and remain crack-free over time, adopting best maintenance practices is essential. Regularly seal and finish surfaces with oil-based or polyurethane coatings to create a moisture barrier that slows drying and cracking. Store your wood in a controlled environment with stable humidity levels around 50-60% and consistent temperatures to prevent moisture fluctuations. Apply end grain sealants or wax to vulnerable points to slow moisture loss and reduce checking risks. Use proper drying techniques, like kiln or controlled air drying, to ensure uniform moisture content before installation or use. Ultimately, periodically inspect your wood and reapply protective treatments as needed to maintain sealing effectiveness. These practices will notably extend your wood’s lifespan and keep it crack-free over the years.

Frequently Asked Questions

How Do You Prevent Wood From Cracking?

To prevent wood from cracking, you should seal it immediately after cutting with products like Anchorseal or wax, especially on end grain surfaces. Store your wood in a controlled environment with stable humidity and temperature to avoid uneven drying. Applying protective finishes such as oil or varnish creates a moisture barrier. Also, keep the wood away from direct sunlight and rapid environmental changes, which can cause cracks over time.

What Do You Put on Wood to Keep It From Cracking?

To keep your wood from cracking, you should apply a sealant like Anchorseal or wax on the end grain, which slows moisture loss. Use oil-based finishes such as linseed or tung oil to create a moisture barrier. If there are existing cracks, fill them with epoxy resin to stabilize the wood. Also, keep your environment consistent, maintaining humidity around 50-60%, to prevent stress-induced cracking.

What Product Keeps Wood From Splitting?

You might think there’s a single product that prevents wood from splitting, but it’s actually a combination of treatments. Applying end grain sealants like Anchorseal, using penetrating oils, or flexible sealants helps maintain moisture balance and allows slight movement. Burying or stacking wood with the same species in shavings extends drying time. These methods work together to keep your wood stable, reducing internal stresses that cause splitting.

How Do You Store Wood so It Doesn’t Crack?

To store wood so it doesn’t crack, you need to keep it in a stable environment. Maintain humidity between 50-60%, and avoid temperature fluctuations. Seal the ends of logs with wax or end grain sealants to slow drying. Store wood off the ground, away from direct sunlight, and use spacers when stacking for good airflow. This way, you prevent uneven moisture loss and thermal stress that cause cracks.

Conclusion

By paying close attention to how your wood breathes and ages, you can gently guide it toward a more graceful, enduring beauty. Embrace careful sealing, proper storage, and patience, knowing these small acts protect the warmth and charm your creations hold. With mindful care, you’ll nurture your wooden pieces through time’s quiet passage, allowing their natural story to unfold beautifully—without unwanted interruptions, but with quiet resilience and gentle grace.