If you’re looking for the best vacuum clamping systems for professional woodworking in 2026, I recommend considering the Laguna CNC Router Vacuum Hold Down Kit, POWERTEC Vacuum Base Vise with Swivel Head, Vacuum Clamp Pod Kit for CNC projects, and the versatile 2-3/4 inch articulated vacuum vise. These systems offer secure, flexible, and precise workpiece hold-downs suitable for advanced woodworking tasks. Keep exploring to discover which solution fits your needs best.

Key Takeaways

- Look for systems with high vacuum pressure (inHg) to ensure secure hold-downs on various woodworking materials.

- Prioritize modular and customizable vacuum pods that can adapt to different workpiece sizes and shapes.

- Choose durable, corrosion-resistant components like phenolic resin pods and aluminum bases for long-term reliability.

- Consider systems with easy installation and quick-release features to optimize workflow efficiency.

- Select solutions with versatile mounting options for seamless integration into professional woodworking setups.

| LAGUNA CNC ROUTER CREATOR VACUUM HOLD DOWN KIT |  | Versatile Large-Area System | Mounting Method: Mount on MDF or aluminum tables | Material: Phenolic resin (vacuum pods) | Connection Type: Vacuum hoses and fittings to venturi | VIEW LATEST PRICE | See Our Full Breakdown |

| POWERTEC Vacuum Base Vise with Swivel Head |  | Portable Precision Vise | Mounting Method: Vacuum suction to smooth surfaces | Material: Die-cast aluminum (vise base) | Connection Type: Vacuum base with locking lever | VIEW LATEST PRICE | See Our Full Breakdown |

| Vacuum Clamp Pod Kit for CNC Projects |  | Quick-Connect Clamping | Mounting Method: T-track, slotted, or screw-mount | Material: Nylon housing with brass fittings | Connection Type: Brass fittings, vacuum hose | VIEW LATEST PRICE | See Our Full Breakdown |

| 2-3/4 Articulated Vacuum Vise |  | Hobbyist’s Compact Vise | Mounting Method: Suction via vacuum base on flat surfaces | Material: Aluminum (articulated vise) | Connection Type: Suction with easy release valve | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

-

POWERTEC Vacuum Base Vise, 2-3/4 Inch Jaw Portable Table Suction Clamp with 360° Swivel Head for DIY Projects, Woodworking, Model Building, Soldering, and Crafts (71016)

DURABLE CONSTRUCTION – Crafted from die cast aluminum, this 2-3/4 inch table suction vise is built to last....

As an affiliate, we earn on qualifying purchases.

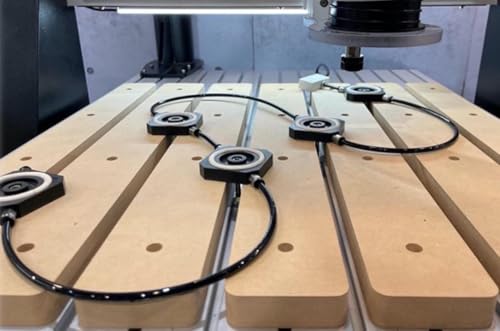

LAGUNA CNC ROUTER CREATOR VACUUM HOLD DOWN KIT

If you’re looking for a reliable vacuum clamping system that offers flexibility and strong hold, the LAGUNA CNC Router Creator Vacuum Hold Down Kit is an excellent choice. It features compact vacuum pods made from phenolic resin, each with their own vacuum seals for secure workpiece hold-downs. You can mount these pods on MDF spoil boards or directly on aluminum tables, using the included screws and T-nuts. Multiple pods connect to cover large areas, accommodating various sizes and shapes. Simply cut hoses to your desired length and connect everything to your vacuum source. Proper sealing and secure mounting guarantee superior performance every time.

- Mounting Method:Mount on MDF or aluminum tables

- Material:Phenolic resin (vacuum pods)

- Connection Type:Vacuum hoses and fittings to venturi

- Adjustability:Flexible pod arrangement

- Size/Capacity:Multiple pods cover large areas

- Intended Use:Securing workpieces on CNC tables

- Additional Feature:Modular pod connection system

- Additional Feature:Compatible with MDF or aluminum

- Additional Feature:Includes vacuum hose fittings

-

Vacuum Clamp Pod Kit w/T Bolt, Fold Down Knobs, Vacuum Hose, Barbed Brass Fitting, & Vacuum Gasket – CNC Clamps for CNC Projects, Routed Signs and Plaques

Vacuum Clamp Pod Kit: Use a vacuum pump (sold separately) with our clamp pod hold down woodworking kit...

As an affiliate, we earn on qualifying purchases.

POWERTEC Vacuum Base Vise with Swivel Head

The POWERTEC Vacuum Base Vise with Swivel Head stands out for its versatile 360-degree rotation and 90-degree tilt, making it ideal for professionals who need precise, multi-angle positioning during woodworking projects. Its durable die-cast aluminum construction offers strength, corrosion resistance, and lightweight portability. The rubber suction base guarantees a secure hold on smooth surfaces like glass or metal, with a locking lever for added stability. The 2-3/4 inch steel V-groove jaw, with replaceable parts and rubber caps, protects delicate workpieces. Its compact size and flexible mounting options make it perfect for hobbyists and small-scale projects requiring versatile, stable clamping.

- Mounting Method:Vacuum suction to smooth surfaces

- Material:Die-cast aluminum (vise base)

- Connection Type:Vacuum base with locking lever

- Adjustability:360° rotation, 90° tilt

- Size/Capacity:Secure objects up to 65mm wide

- Intended Use:Clamping on smooth surfaces for hobby/DIY

- Additional Feature:360° rotation capability

- Additional Feature:Rubber jaw caps included

- Additional Feature:Lightweight at 3.14 lbs

-

Central Forge 2-3/4 Articulated Vacuum Vise

Universal joints for 360 deg. horizontal adjustment, 180º vertical adjustment

As an affiliate, we earn on qualifying purchases.

Vacuum Clamp Pod Kit for CNC Projects

Designed specifically for CNC projects, the Vacuum Clamp Pod Kit offers a reliable and efficient way to hold workpieces securely without obstructing access to edges or surfaces. It uses a dedicated vacuum pump to clamp items from underneath, eliminating traditional clamps that can get in the way. The kit includes two nylon housing pods with brass fittings, a vacuum hose, gasket, and T-bolts for versatile mounting options like T-tracks or screw mounts. Made with durable materials, it supports quick activation and release, streamlining workflows. Perfect for routed signs, plaques, or general fixturing, this system enhances precision while maintaining unobstructed access during machining.

- Mounting Method:T-track, slotted, or screw-mount

- Material:Nylon housing with brass fittings

- Connection Type:Brass fittings, vacuum hose

- Adjustability:Quick activation and release

- Size/Capacity:2 vacuum clamp pods

- Intended Use:Workpiece fixturing during CNC routing

- Additional Feature:Multiple mounting options supported

- Additional Feature:Brass fittings for secure hold

- Additional Feature:Quick activation and release

2-3/4 Articulated Vacuum Vise

The 2-3/4 Articulated Vacuum Vise stands out for hobbyists and small-scale craftsmen who need precise, versatile clamping during detailed work. Its universal joints allow 360° horizontal and 180° vertical adjustments, giving me flexibility in positioning. Made from lightweight yet sturdy cast aluminum, it’s easy to handle and transport. The rubber jaw pads protect delicate workpieces, while the easy suction release makes setup quick. I’ve used it for painting figurines, repairing RC cars, and intricate projects. Despite being discontinued, it remains available and reliable for those who need a portable, adaptable vacuum vise. It’s a practical choice for precision hobbyist applications.

- Mounting Method:Suction via vacuum base on flat surfaces

- Material:Aluminum (articulated vise)

- Connection Type:Suction with easy release valve

- Adjustability:360° horizontal, 180° vertical joints

- Size/Capacity:Suitable for small projects, lightweight

- Intended Use:Hobbyist/model work, detailed projects

- Additional Feature:Articulated joints for angles

- Additional Feature:Rubber jaw pads protect work

- Additional Feature:Discontinued but available

Factors to Consider When Choosing a Vacuum Clamping System for Professional Woodworking

When choosing a vacuum clamping system, I focus on how well it works with different materials and the strength of its hold. Ease of installation and how versatile the system is also matter a lot to me, along with its durability and maintenance needs. Considering these factors helps make certain I pick the right system for professional woodworking tasks.

Compatibility With Materials

Choosing the right vacuum clamping system means guaranteeing it’s compatible with the materials you’ll work with, as this affects both hold strength and surface integrity. I always check that the system’s seals and materials match the type of wood or composites I use, preventing damage or weak holds. It’s essential to verify that vacuum pods or clamps grip the surface textures and thicknesses of my workpieces securely. I also confirm the system can generate enough force for the size and weight of projects without causing deformation. Additionally, I look for vacuum components resistant to wood dust and moisture, which can compromise their seals over time. Finally, I ensure the system can handle different shapes and sizes, giving me versatility across various woodworking tasks.

Vacuum Power and Hold

Vacuum power plays a critical role in guaranteeing that your workpieces stay securely in place during woodworking. The level of vacuum directly influences the maximum holding force, which is essential for preventing slips during cutting or sanding. Higher vacuum levels, measured in inches of mercury (inHg), provide stronger adhesion, especially important when working with uneven or porous surfaces. The effectiveness of vacuum hold depends on the integrity of seals and the vacuum volume generated by the pump or system, impacting overall stability. Consistent vacuum pressure is crucial for maintaining a reliable grip throughout machining. Additionally, the size and number of vacuum cups or pods matter, as they affect force distribution based on the workpiece’s dimensions and weight. Choosing the right vacuum power ensures safety and precision in your woodworking projects.

Ease of Installation

Installing a vacuum clamping system should be straightforward to save time and minimize frustration on busy workdays. I look for systems that require minimal tools and steps for setup, making installation quick and hassle-free. Compatibility with existing workbenches or CNC tables is essential, so I check if the vacuum pods or bases can easily mount without modifications. Clear instructions or mounting templates simplify alignment and attachment, reducing guesswork. I also prefer systems that allow modular expansion or reconfiguration without complex disassembly, so I can adapt to different projects efficiently. Finally, straightforward connections like quick-connect fittings and hose attachments are a must, as they minimize downtime and technical effort. A simple installation process helps me stay focused on woodworking rather than setup complications.

Versatility and Flexibility

A versatile vacuum clamping system is essential for handling a variety of workpiece sizes and shapes without the need for multiple fixtures. It adapts easily to different projects, saving time and effort. Flexibility in connection options, like adjustable hoses and modular pods, allows me to customize setups for specific tasks. The ability to quickly reconfigure vacuum pod placements boosts productivity during complex woodworking. Systems with adaptable mounting methods—such as T-track or screw mounts—fit various work surfaces and workshop layouts seamlessly. Additionally, adjustable vacuum pressure controls guarantee secure holding across diverse materials and thicknesses, making the system highly versatile. Overall, these features help me streamline workflows, tackle different projects efficiently, and maximize the use of my workspace.

Durability and Maintenance

Choosing a durable vacuum clamping system means investing in equipment built to withstand daily use and challenging workshop conditions. I opt for systems made from high-quality, corrosion-resistant materials like phenolic resin or aluminum, ensuring longevity. Regularly inspecting and replacing worn seals and gaskets is vital to maintaining ideal vacuum pressure and preventing leaks. I also make sure the vacuum pods or bases are compatible with my work surface and easy to clean, which helps avoid dirt buildup that can compromise the seal. Using modular fittings and quick-release valves makes maintenance straightforward and efficient. Finally, I prefer systems with robust construction and minimal moving parts to reduce mechanical failure risks and simplify ongoing upkeep, ensuring reliable performance over time.

Frequently Asked Questions

How Do Vacuum Clamping Systems Impact Workpiece Finish Quality?

Vacuum clamping systems considerably improve workpiece finish quality by providing even, consistent pressure across the surface. I’ve found that they minimize marks and distortions caused by traditional clamps, resulting in a cleaner, smoother finish. Plus, since there’s no need for mechanical clamps that can mar the wood, the overall quality of the workpiece looks more professional. They really help me achieve a flawless finish every time I work on a project.

Can Vacuum Systems Be Used With Irregularly Shaped Wood Pieces?

Yes, vacuum systems can be used with irregularly shaped wood pieces. I’ve found that flexible, adjustable vacuum pads and specialized foam or rubber inserts help create a secure seal around uneven surfaces. By adapting the system to the shape, I can hold awkward or complex pieces firmly without damaging the wood. It’s a versatile solution that gives me confidence working on even the most challenging shapes.

What Maintenance Is Required for Long-Term Vacuum System Performance?

You bet I keep a close eye on my vacuum system! I regularly check for leaks, clean filters, and guarantee seals are intact. I also monitor pressure gauges daily and replace worn hoses promptly. A little preventive maintenance goes a long way—think of it as giving your system a spa day. Staying vigilant means my vacuum stays powerful, reliable, and ready for anything, even the quirkiest wood pieces.

Are Vacuum Clamps Suitable for Heavy-Duty Industrial Woodworking?

Yes, vacuum clamps can handle heavy-duty industrial woodworking, but it depends on the system’s design and capacity. I’ve found that high-powered vacuum systems with robust seals and strong pumps are vital for larger, thicker materials. Proper maintenance is indispensable to guarantee they don’t lose suction or face leaks. When set up correctly, vacuum clamps provide reliable, consistent holding power, even for demanding industrial applications.

How Do Vacuum Systems Compare to Traditional Clamping Methods in Speed?

They say time is money, and vacuum systems definitely save time compared to traditional clamps. I’ve found that vacuum setups can secure workpieces in seconds, whereas manual clamps often take longer to position and tighten. This speed boost keeps projects moving smoothly and increases productivity. If you’re after efficiency, vacuum systems are a game-changer, making the entire process faster without sacrificing precision or strength.

Conclusion

Choosing the right vacuum clamping system can truly elevate your woodworking projects. Whether you need precision, versatility, or ease of use, there’s an option that fits your needs. Have you considered how these systems could streamline your workflow and improve your results? Don’t settle for less—invest in the best to release your full potential. After all, isn’t achieving perfect, secure holds worth it in every project?