3D printing in woodworking lets you craft custom tools, jigs, and fixtures, boosting your precision and efficiency. You can design unique router bits, clamps, or sanding aids tailored to your projects, saving time and costs. However, material limitations mean not all prints are suitable for heavy-duty use, and some parts need extra post-processing for durability. To *access* your full potential with 3D printing in woodworking, explore the detailed applications and considerations ahead.

Key Takeaways

- 3D printing enables custom tool fabrication and complex geometries tailored to specific woodworking tasks.

- It allows in-house production of jigs, templates, and finishing aids, speeding up workflows.

- Material limitations can affect durability; some printed tools require post-processing for professional use.

- It supports rapid prototyping, reducing costs and time for small-scale tool development.

- Knowledge of material properties and limitations is essential for ensuring long-lasting, functional printed tools.

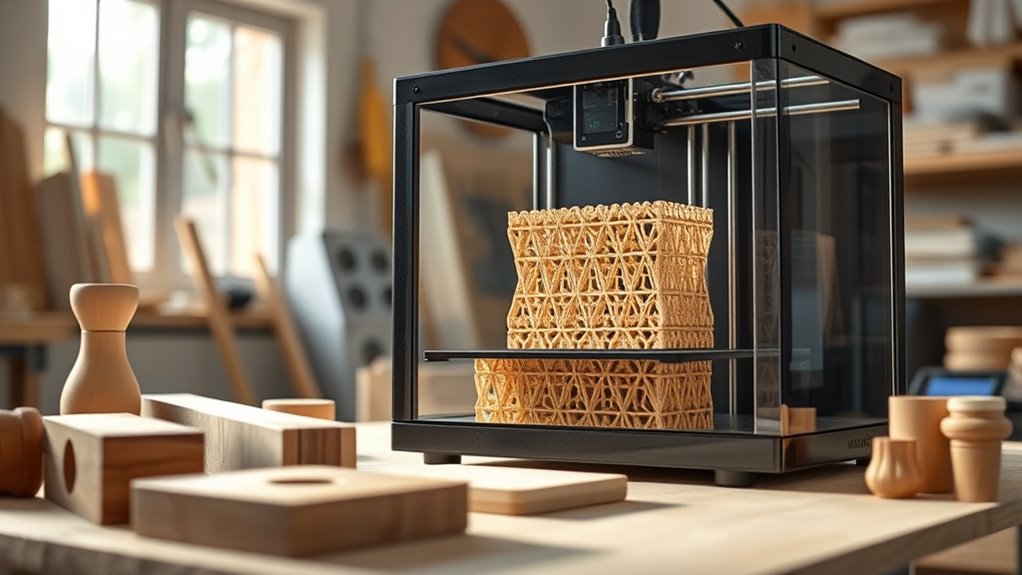

Have you ever wondered how 3D printing is transforming traditional woodworking? It’s changing the way you approach projects, especially in areas like custom tool fabrication and surface finishing techniques. Instead of relying solely on conventional tools and methods, you can now design and produce specialized tools tailored precisely to your needs. Whether you need a unique router bit or a custom clamp, 3D printing allows you to craft these tools quickly and cost-effectively. This not only saves time but also enhances your ability to experiment with innovative designs that might be difficult or expensive to produce through traditional manufacturing processes.

With 3D printing, you gain the ability to create complex geometries that were once impossible to achieve with standard machining. This is particularly useful when developing custom tools that fit specific woodworking projects or workflows. For example, you can design jigs, templates, or specialized fixtures that streamline your work, all while maintaining a high level of precision. Moreover, 3D-printed tools can be made from various materials suited for woodworking environments, providing durability without sacrificing ease of customization. This flexibility means you can iterate designs rapidly, improving tools on the fly without waiting for external suppliers or manufacturers.

Surface finishing techniques also benefit from 3D printing integration. After printing, you can refine your project’s surface to achieve a polished, professional look. Techniques like sanding, filing, or even applying coatings become more manageable when combined with 3D-printed parts or accessories. For instance, you might print custom sanding blocks or polishing aids tailored to specific contours or surfaces. The ability to produce these items in-house accelerates your workflow, saves money, and ensures you can maintain consistent quality. Plus, 3D printing allows you to create intricate patterns or textures that can be incorporated into your woodworking projects, adding aesthetic value that would be difficult with traditional methods.

However, it’s essential to recognize the limitations. Not all materials used in 3D printing are suitable for heavy-duty or high-temperature applications, which could restrict the use of certain printed tools in demanding woodworking tasks. Surface finish quality depends heavily on the printing process and material, meaning some parts may require additional post-processing to meet professional standards. Despite these constraints, 3D printing offers a powerful means to enhance your capabilities, especially in custom tool fabrication and surface finishing, giving you more control, creativity, and efficiency in your woodworking projects. Additionally, understanding 3D printing materials and limitations helps you select appropriate options for your specific needs and ensures long-lasting results.

2Pack Pipe Drilling Guide Block – 3D Printed Handheld Drilling Jig for Precision Straight Holes, Woodworking and Pipefitter Accessory

Precision Drilling Tool: Designed as a handheld drilling guide, this tool ensures straight and accurate holes in pipes,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

What Types of Wood Are Compatible With 3D Printing?

You can use hardwoods like maple, cherry, and walnut for 3D printing, but most often, softwoods like pine and cedar are compatible because of their lighter density. When considering wood compatibility, focus on filament selection—composite filaments with wood fibers work best. Guarantee your printer handles the filament’s properties, such as temperature and flow, to achieve quality results. Always test small batches before progressing to larger projects.

How Cost-Effective Is 3D Printing for Small Woodworking Projects?

You might find 3D printing cost-effective for small woodworking projects, especially when considering material versatility. While the initial investment can be high, it often pays off by saving time and reducing waste. When doing a cost comparison, 3D printing can be cheaper for intricate or custom parts. However, for simple projects, traditional methods might still be more economical—it’s all about weighing the pros and cons.

Can 3D Printed Wood Components Be Recycled or Reused?

Yes, 3D printed wood components can be recycled or reused. Recycling processes involve grinding or melting the material, which reduces environmental impact by minimizing waste. You can reuse parts in other projects or repurpose them creatively. Keep in mind that the environmental benefits depend on the type of material used and the availability of suitable recycling options, making it a more sustainable choice when managed properly.

What Safety Precautions Are Necessary When 3D Printing With Wood Filaments?

Think of 3D printing with wood filaments like handling a delicate fire; safety is vital. Always wear a mask to prevent inhaling dust, and make certain proper dust management systems are in place. Keep a fire extinguisher nearby, as wood-based filaments can be flammable, especially at high temperatures. By taking these precautions, you protect yourself and your workspace, turning potential hazards into safe, creative projects.

How Does 3D Printing Impact Traditional Woodworking Craftsmanship?

3D printing impacts traditional woodworking craftsmanship by blending innovative design with craftsmanship preservation. It allows you to create complex, customized pieces efficiently, expanding your creative possibilities. While it introduces new techniques, it also challenges traditional skills, urging you to adapt and incorporate technology into your craft. This fusion helps preserve craftsmanship while pushing the boundaries of woodworking, inspiring fresh ideas and innovative projects that honor tradition yet embrace modern advancements.

IDGGDI 10pcs CNC Router V Bits, 3 Edge Pyramid Engraving, 1/8" Shank CNC 3D Milling Cutter| 20/30/45/60/90 Degrees, 0.1mm Tip

【Wide Applications】It is widely used to engrave, drill, mill, cut and carve on natural wood, hardwood, plywood, acrylic,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Like Da Vinci’s sketches hint at future innovation, 3D printing opens new doors in woodworking, blending tradition with technology. While its applications inspire creativity and efficiency, limitations remind us to stay grounded. Embrace the possibilities, but respect the boundaries—much like a craftsman mastering both chisel and digital tool. With careful balance, you can carve a path forward, transforming your woodworking journey into a harmonious dance of craftsmanship and innovation.

HORUSDY 8-Pack Bar and Spring Clamps for Woodworking – 4 Pieces 6" Bar, 4 Pieces 4" Spring, 75 LBS Load Limit, Quick F Clamp Set

WHAT CAN YOU GET – This set includes 4 pieces of 6-inch woodworking bar clamps and 4 pieces…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Honoson 20 Pcs Sanding Sticks for Plastic Models 3D Print Polishing Sticks Assorted Metal and Wood Sanding Tools Accessory for Model Craft Amateur Beginner(Low Grits and High Grits,Water Drop Style)

Package list: you will receive 20 pieces of model sanding sticks in 20 different grits as 80, 180,…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.