Hardboard is made from compressed wood fibers and lignin, which bonds fibers naturally with minimal adhesives. It comes in various types, from low to high density, suitable for uses like furniture, flooring, and crafts. Its durability, strength, and environmental friendliness make it popular in construction and DIY projects. Thanks to its versatility and eco benefits, hardboard is a smart choice for many applications. Keep exploring to discover how its properties can work for your projects.

Key Takeaways

- Hardboard is a dense, durable engineered wood made from compressed wood fibers bonded mainly by natural lignin.

- It is widely used in furniture backing, wall panels, flooring underlayment, and crafts due to its strength and smooth surface.

- Manufactured with high pressure and temperature, emphasizing sustainability through recycled wood materials and low chemical emissions.

- Offers benefits like excellent durability, impact resistance, sound insulation, and the ability to be finished with paints or veneers.

- Its environmentally friendly, recyclable nature makes hardboard a cost-effective and sustainable building and crafting material.

Composition and Manufacturing of Hardboard

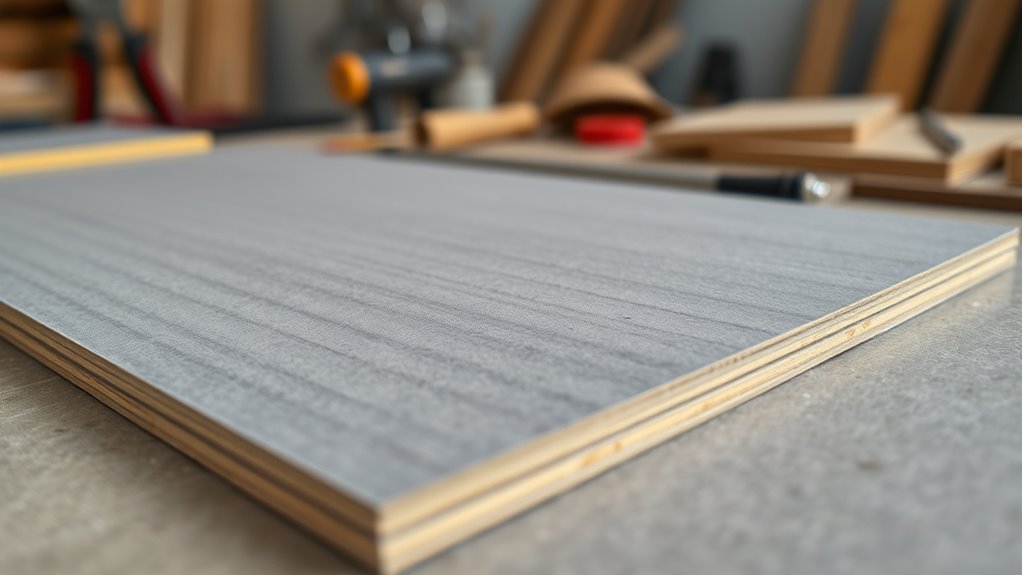

Hardboard is made by compressing wood fibers or sawdust into dense sheets using high heat and pressure. During manufacturing, wood fibers are sheared, refined, and washed, often in a wet process like the Masonite method, which produces smooth, durable sheets. The compression applies high heat and pressure to bond the fibers densely, primarily relying on natural lignin in the wood rather than synthetic adhesives. Sometimes, the fibers are mixed with resins or waxes before pressing, but many hardboards are formed without added adhesives. The fibers are carefully refined to ensure uniformity, resulting in a tightly laminated sheet with a density typically between 800 and 1,040 kg/m³. This process creates a hard, solid material that is often made from recycled wood or paper waste, emphasizing sustainability. Additionally, the properties of hardboard—such as its strength and stability—are greatly influenced by the manufacturing process, making it a versatile material for various applications. The horsepower of electric dirt bikes can also influence the durability and performance of the material in certain industrial uses. Understanding the cybersecurity vulnerabilities involved in manufacturing equipment can further improve safety and efficiency in production. Furthermore, advancements in production technology continue to enhance the quality and environmental impact of hardboard manufacturing, including the integration of AI security measures to protect manufacturing systems from cyber threats.

Types and Classifications of Hardboard and Fiberboards

Have you ever wondered how different types of fiberboards are classified for various uses? The key factor is density, which determines their classification. Here’s what you need to know:

Fiberboard types are classified mainly by their density, influencing their specific applications and manufacturing standards.

- Low-density fiberboards (LDF): With densities around 0.15–0.45 g/cm³, mainly used for insulation and decorative purposes. Their lightweight nature makes them ideal for thermal insulation applications. Incorporating sound absorption qualities can enhance their effectiveness in acoustic management.

- Medium-density fiberboards (MDF): Ranging from 0.6–0.8 g/cm³, suitable for furniture and cabinetry, produced using specific manufacturing processes and EN standards. MDF offers a good balance of strength and workability.

- High-density fiberboards (HDF): Around 0.85–1.2 g/cm³, including hardboard like Masonite, known for high strength and impact resistance, especially when tempered. Their high density is achieved through compression techniques that enhance durability. The manufacturing methods are crucial for maintaining consistent quality and performance.

Hardboard’s high-density classification results from compressed wood fibers, manufacturing techniques, and temperature control, aligning with EN standards for quality. Additionally, merchants’ adoption of advanced production methods ensures consistent density and performance across different fiberboard types.

Common Applications and Industry Uses

Thanks to its durability and smooth surface, hardboard is a popular choice across various industries. Its applications include furniture, where it serves as backing panels for cabinets, drawers, and shelving. You’ll also find hardboard used as wall panels and interior cladding in both homes and commercial spaces, thanks to its impact resistance and surface quality. It functions effectively as flooring underlayment beneath carpets, tiles, or vinyl, providing a stable, impact-resistant base. Artists and hobbyists value it as a paintable surface for projects like signs and crafts. In DIY projects, hardboard is easy to cut and shape, making it ideal for model-building and decorative panels. Its versatility and durability make hardboard a reliable option across many industries. Additionally, understanding the local business hours of suppliers and retailers can help ensure timely procurement of hardboard and related materials for various projects. Moreover, the automation in business sector highlights how manufacturing processes like hardboard production benefit from technological advancements to improve efficiency. Staying aware of grocery store hours can also assist in planning the procurement of necessary materials, especially during busy or holiday seasons.

Advantages and Sustainability Aspects

Built from recycled wood fibers and waste materials, hardboard offers an environmentally friendly option that reduces the demand for virgin timber. Its manufacturing process uses natural lignin, resulting in low chemical emissions and making it a safe, eco-friendly choice. Hardboard’s high density and durability ensure long-lasting applications, supporting sustainability by enabling reuse. Additionally, its versatile nature allows it to be used in various projects, from furniture to construction. As a biodegradable and recyclable material, hardboard helps minimize waste and environmental impact. Its recycling potential makes it a preferred option for sustainable building practices. Its environmental benefits further contribute to reducing ecological footprints, making it a sustainable choice for many industries. Incorporating meditative practices such as mindfulness can also promote overall well-being and environmental mindfulness. Exploring the life cycle analysis of hardboard can provide deeper insights into its sustainability credentials.

Comparing Hardboard to Other Engineered Wood Materials

How does hardboard compare to other engineered wood materials like particle board and MDF? Hardboard is denser and harder, with a density between 800 and 1,040 kg/m³, offering superior impact resistance and durability. Unlike particle board and MDF, it bonds wood fibers through compression and natural lignin, eliminating adhesives. Its homogeneous surface is ideal for finishing, unlike particle board’s rougher texture. Additionally, its high density contributes to better structural integrity, making it suitable for a variety of demanding applications. Its manufacturing process involves pressing wood fibers under high heat and pressure, which enhances its strength and uniformity. The environmental impact of hardboard is also generally favorable due to its minimal use of adhesives. Here’s a quick comparison:

| Material | Surface Finish | Impact Resistance | Density (kg/m³) |

|---|---|---|---|

| Hardboard | Smooth, homogeneous | High | 800-1040 |

| Particle Board | Rougher, needs treatment | Moderate | 600-800 |

| MDF | Smooth, but less dense | Moderate | 600-800 |

This makes hardboard more cost-effective and versatile for heavy-duty projects, especially when considering its fire safety properties and durability.

Frequently Asked Questions

What Is the Composition of Hardboard?

When you ask about hardboard’s composition, you’re looking at a dense, solid material formed by compressing wood fibers or recycled paper under high heat and pressure. These fibers, mainly wood pulp or sawdust, naturally bond through lignin, acting as a glue. Sometimes resins are added for extra strength. This process produces a durable, uniform sheet ideal for various building and craft projects.

What Are the Three Types of Hardboard?

Imagine a toolbox with three unique tools, each designed for a specific task. You have standard hardboard, like a versatile canvas with a smooth and rough side, perfect for various projects. Tempered hardboard acts like a sturdy shield, treated for water resistance and impact. Perforated hardboard, or pegboard, is your organizational hero, with holes ready to hold hooks and accessories. Together, these three types meet all your construction, artistic, and organizational needs.

What Can You Use Hardboard For?

You can use hardboard for a variety of projects and applications. It works well as backing panels for furniture, interior wall coverings, and flooring underlayment. It’s also great for craft projects like signs and models, thanks to its easy cutting and shaping. Additionally, with proper treatment, you can use hardboard for exterior siding, making it a versatile material for both indoor and outdoor uses.

Can I Paint Directly on Hardboard?

You can definitely paint directly on hardboard. Imagine a smooth, dense surface ready for your brushstrokes—no priming needed if it’s properly prepared. Just clean, dry, and lightly sand the surface to remove imperfections. For best results, apply a primer or sealant to boost paint adhesion and longevity. This sturdy surface supports detailed work and withstands framing and handling, making it perfect for your artistic projects.

Conclusion

In the world of building materials, hardboard stands as a sturdy friend—versatile, reliable, and eco-friendly. Like a dependable companion, it seamlessly adapts to your needs, offering strength and sustainability in every grain. Embrace its many uses, and you’ll find it’s a true workhorse that’s both kind to the environment and ready to support your projects. Hardboard isn’t just a material; it’s the silent hero behind many successful creations.