Bridle joints provide a perfect balance between simplicity and strength, making them ideal for many woodworking projects. They involve cutting a mortise and tenon that fit together tightly, creating a durable connection at right angles. This joint distributes loads evenly and resists twisting over time, offering excellent structural integrity. You can also enhance their appearance with decorative touches. If you’d like to discover how to master this versatile joint, there’s more to explore below.

Key Takeaways

- Bridle joints offer a simple yet strong connection by fitting a tenon into a mortise, ensuring solid structural integrity.

- Their large gluing surface distributes loads evenly, resisting twisting and pulling apart over time.

- Precise cutting and fitting are essential for optimal strength, making them accessible for both novices and experienced woodworkers.

- Reinforcing with pegs, dowels, or glue enhances the joint’s durability without complicating the construction process.

- They can be customized aesthetically, blending functionality with decorative appeal in furniture and frame projects.

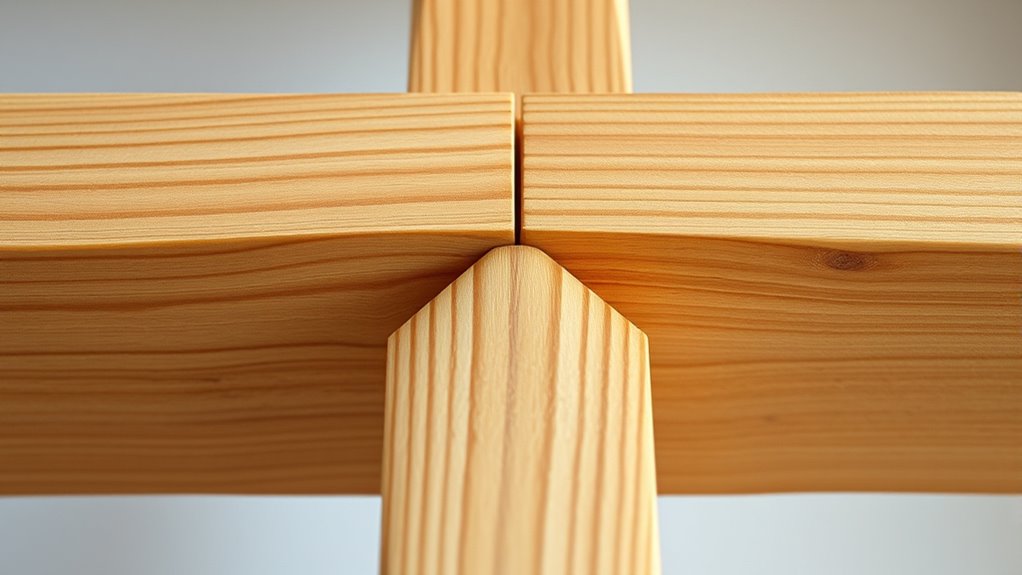

A bridle joint is a strong woodworking connection used to join two pieces at right angles, often in frames and furniture. It’s prized for its simplicity and durability, making it a popular choice for both functional and aesthetic projects. When you use a bridle joint, you’re not just creating a sturdy connection—you’re also enhancing the overall strength of your piece through effective joint reinforcement. The joint’s design allows for a large gluing surface, which helps distribute loads evenly and resist twisting or pulling apart over time. This makes it ideal for structural elements that need to withstand stress, such as door frames, chair legs, or cabinet corners. Additionally, proper fitting and precise cutting**** are crucial to ensure the joint functions optimally and maintains its integrity over years of use.

A bridle joint offers a strong, durable connection ideal for structural woodworking and furniture projects.

In addition to its strength, the bridle joint offers opportunities for decorative detailing. You can customize the joint by adding contrasting wood inlays or carving subtle patterns along the edges, turning a simple joint into an eye-catching feature. When you incorporate decorative elements, it elevates the craftsmanship and gives your project a personalized touch. This is especially valuable in furniture making, where the joint can serve as a visual focal point or a design accent. Whether you choose a clean, minimalist look or opt for intricate carvings, the bridle joint lends itself well to embellishment without sacrificing its structural benefits.

To create a reliable bridle joint, you need to pay close attention to the fit. Precise cutting ensures the joint slides together snugly, maximizing joint reinforcement and minimizing gaps that could weaken the connection. You’ll typically cut a mortise in one piece and a corresponding tenon in the other, ensuring they align perfectly. Using sharp tools and careful measuring is essential here. Once assembled, you might reinforce the joint further with pegs, dowels, or glue, depending on your project’s needs. This additional reinforcement enhances durability and ensures your joint remains intact through years of use.

When you incorporate bridle joints into your work, you’re combining simplicity with strength. The joint’s straightforward design makes it accessible for both novice and experienced woodworkers, yet its structural integrity rivals more complex joinery methods. Plus, with some creative decorative detailing, you can make each joint a signature element of your piece. Whether you’re building a sturdy chair, a decorative frame, or a custom cabinet, the bridle joint offers a balanced blend of practicality and aesthetic appeal. It’s a tribute to how a well-executed, simple joint can elevate your woodworking projects, providing both function and beauty in one efficient connection.

Frequently Asked Questions

What Are the Best Wood Types for Bridle Joints?

You should choose hardwoods like oak, maple, or cherry for bridle joints because their tight grain orientation provides strength and durability. These woods respond well to proper wood treatment, which enhances their structural integrity. Avoid softwoods with loose grain, as they’re prone to splitting. By selecting the right wood type and ensuring proper grain orientation and treatment, your bridle joints will be both strong and long-lasting.

How Do Bridle Joints Compare to Other Woodworking Joints?

You might think bridle joints are just plain, but they actually pack a punch in joint strength while adding a sleek aesthetic appeal. Compared to dovetails or mortise and tenons, they’re simpler and quicker to make—yet surprisingly durable. Sure, they lack the ornate charm of some joints, but if you want a balance of strength and clean look, bridle joints are the understated hero in your woodworking toolkit.

Can Bridle Joints Be Used in Load-Bearing Furniture?

Yes, you can use bridle joints in load-bearing furniture, especially when combining their strength with decorative applications. Their historical significance highlights their durability and versatility in traditional woodworking. You’ll find them effective for connecting vertical and horizontal members, providing both structural integrity and aesthetic appeal. Just guarantee proper craftsmanship, as the joint’s strength depends on precise fitting and quality materials, making it suitable for furniture that needs to support weight over time.

What Tools Are Essential for Creating Precise Bridle Joints?

Did you know precise joinery techniques like bridle joints can substantially strengthen furniture? To achieve this, you need essential tools such as a saw, chisel, marking gauge, and square. These tools help you cut accurately and fit pieces perfectly. Always prioritize woodworking safety by wearing protective gear and working carefully. With the right tools and safety measures, you’ll create strong, elegant bridle joints that enhance your furniture’s durability and aesthetic appeal.

How Do Environmental Factors Affect the Durability of Bridle Joints?

Environmental factors like moisture fluctuations and temperature changes can considerably impact the durability of your bridle joints. When moisture levels vary, wood expands and contracts, potentially causing joints to loosen or crack over time. Temperature swings can weaken adhesives or cause wood to warp. To enhance longevity, choose stable woods, apply proper sealants, and ensure proper construction techniques that accommodate these environmental changes, keeping your joints strong and reliable.

Conclusion

So, next time you’re faced with a tricky corner, remember bridle joints—your trusty, no-nonsense friends in woodworking. They’re simple enough for beginners, yet strong enough to hold your masterpiece together. Who knew that a humble joint could be so versatile? Skip the fancy gadgets and give these classic connectors a shot. After all, why settle for flimsy alternatives when you can have the perfect blend of simplicity and strength? Happy building!