Did you know that nearly 60% of the audio experience in a room comes from the subwoofer alone? This often-overlooked component dramatically influences your sound quality, making the construction of its box a crucial element in achieving exceptional audio performance. Selecting the best subwoofer box materials plays an essential role in facilitating optimal resonance and sound absorption. By scrutinizing various materials, you can elevate your listening experience one note at a time, ensuring that your system delivers rich, deep bass without distortion. In this section, we will delve into the various materials available and their unique properties that contribute to audio quality enhancement.

Key Takeaways

- The subwoofer significantly impacts overall audio quality.

- Material selection is vital for effective sound absorption.

- Quality construction influences resonance and bass performance.

- Exploration of various materials can enhance your listening experience.

- Understanding audio quality enhancement is key to optimal sound.

Understanding the Importance of Subwoofer Box Construction

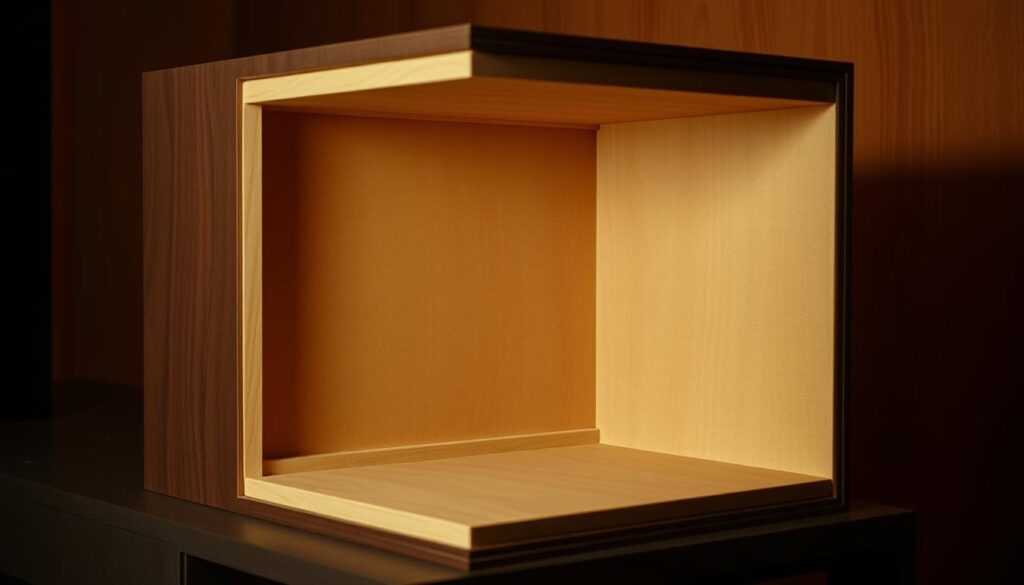

Subwoofer box construction plays a crucial role in achieving optimal audio performance. A well-designed enclosure offers the necessary environment for the subwoofer to thrive, contributing significantly to refined bass response and overall sound clarity. When selecting materials for your enclosure design, consider not only the sound quality implications but also how the box dimensions interact with the chosen components.

Quality subwoofer box construction involves creating a rigid structure that minimizes distortion and resonance. By using sturdy materials and ensuring airtight seals, you create an optimal space for the subwoofer to operate, enhancing its performance and longevity. Furthermore, appropriate enclosure design supports better air movement, further maximizing bass output.

Whether you are a seasoned audiophile or just starting your journey into high-quality sound, understanding the fundamentals of subwoofer box construction is essential. Take the time to explore various aspects like material choice, box size, and overall enclosure design to truly elevate your listening experience.

The Role of Subwoofer Boxes in Enhancing Audio Quality

Subwoofer boxes play a crucial role in enhancing audio quality by effectively managing sound waves generated by the subwoofer. When properly designed, these enclosures reproduce low-frequency sounds that typical speakers may struggle to deliver. This capability fills in gaps within the audio spectrum, leading to a richer and more immersive listening experience.

One of the primary functions of a subwoofer box is to enhance bass response. The enclosure creates a controlled environment for the subwoofer, allowing it to perform optimally. The materials chosen for building the box can significantly impact how well bass frequencies are reproduced. In turn, this also influences overall sound clarity, ensuring that every note and beat comes through with precision.

By focusing on both the design and materials of the subwoofer box, you can ensure that your audio system delivers the quality you expect. Well-constructed enclosures not only enhance audio quality but also provide a solid foundation for your entire sound setup, delivering an exceptional auditory experience that resonates with music enthusiasts and casual listeners alike.

Best Sound Absorbing Materials for Subwoofer Box Construction

When it comes to building subwoofer boxes, selecting the right sound absorbing materials is crucial for achieving optimal audio performance. Two materials stand out for their exceptional qualities: Medium Density Fiberboard (MDF) and High-Density Fiberboard (HDF). Both options offer unique benefits that can enhance your audio construction.

MDF: The Gold Standard

MDF is often regarded as the gold standard for subwoofer box construction due to its excellent density and stability. This material effectively absorbs sound, which minimizes resonance and distortion. The smooth surface of MDF permits the creation of airtight enclosures, essential for delivering clean and accurate sound. Its favorable sound absorbing properties make it a go-to choice for many audio enthusiasts.

High-Density Fiberboard (HDF) Benefits

While HDF typically comes with a higher price tag, its superior rigidity and sound absorbing capabilities make it an appealing option for high-performance audio projects. HDF’s dense structure allows for enhanced sound quality, ensuring that your audio construction achieves professional-level results. Utilizing HDF can elevate your subwoofer’s performance, resulting in a richer and more distinct listening experience.

The Robustness of Medium Density Fiberboard (MDF)

Medium Density Fiberboard (MDF) has gained recognition in subwoofer box construction due to its exceptional MDF properties. The material’s high density plays a crucial role in its performance. Understanding its benefits can help you make informed choices when crafting your audio setup.

Density and Stability

The density of MDF directly contributes to the stability of your subwoofer enclosure. Thicker MDF boards, typically around 3/4” or 1”, create a sturdy framework that minimizes flexing. This rigidity is vital for achieving accurate sound reproduction. A stable box reduces unwanted resonance that can distort audio output. With MDF, you gain not only strength but also an assurance of durability.

Sound Quality Enhancement

When it comes to sound quality, MDF excels as a material choice. The controlled resonance provided by MDF ensures cleaner and more precise audio. This results in a deeper bass response and enhanced clarity, which many audiophiles seek in their systems. By utilizing MDF in your subwoofer box, you can optimize the overall auditory experience.

| MDF Characteristics | Impact on Audio Performance |

|---|---|

| High Density | Reduces distortion and flexing |

| Stability | Enhances bass response |

| Controlled Resonance | Improves sound clarity |

| Workability | Allows precise cuts for tight fits |

The Versatility of Plywood in Sub Box Construction

Plywood stands as a versatile option among sub box materials, offering a unique blend of durability and aesthetic appeal. One of the most notable plywood advantages is its strength, especially when utilizing higher-grade varieties such as birch plywood. This material is designed to resist warping, which makes it a reliable choice in audio construction.

The layered structure of plywood minimizes sound distortion effectively. This characteristic enhances the overall bass response, allowing for a more enjoyable listening experience. Custom audio designers often select plywood for its ability to accommodate creative shapes tailored to specific subwoofer designs.

Plywood’s resilience to environmental changes contributes to the longevity of subwoofer boxes. Regardless of climate fluctuations, this material tends to maintain its integrity better than many alternatives. Its versatility not only provides practical benefits but also offers a range of aesthetic options for builders looking to create visually appealing audio setups.

| Material | Strength | Sound Performance | Environmental Resistance | Aesthetic Flexibility |

|---|---|---|---|---|

| Plywood | High | Excellent | Above Average | High |

| MDF | Medium | Good | Low | Medium |

| HDF | Medium | Good | Medium | Low |

Exploring Unconventional Materials for Sub-Box Building

When expanding your options in subwoofer box construction, considering unconventional materials can lead to remarkable audio enhancement. Materials like fiberglass and polycarbonate provide unique benefits that traditional options may lack. These innovative choices cater to both the functionality and design of your audio setup.

Fiberglass: The Custom Fit

Fiberglass has become a favorite among audio enthusiasts for its versatility. This material allows you to create custom-shaped enclosures, making it ideal for tight spaces or unconventional design needs. Fiberglass offers significant benefits, including:

- Strength: Its robust nature ensures durability even in challenging environments.

- Low Resonance: Fiberglass minimizes vibrations, resulting in cleaner sound quality.

- Lightweight: This material is easier to handle during installation, especially for complex shapes.

Polycarbonate: Lightweight Durability

Polycarbonate stands out as a lightweight and durable alternative for subwoofer construction. Its impressive impact resistance and versatility allow for multiple aesthetic designs, enhancing the overall look of your audio system. Here are some reasons to consider polycarbonate for your sub-box:

- Durability: Polycarbonate can withstand rough conditions, ensuring longevity.

- Lightweight: Easier transportation and installation, particularly in mobile setups.

- Modern Aesthetic: Its sleek appearance contributes to a stylish finish in any audio setup.

Factors to Consider When Choosing Sub Box Material

Making informed decisions when choosing sub box material is essential for achieving optimal sound quality. The selected material profoundly influences various sound quality factors, such as clarity, depth, and overall audio performance. Quality materials often translate into enhanced listening experiences, which is why understanding the attributes of each option is crucial.

Impact of Material on Sound Quality

The performance of a subwoofer largely hinges on the material used in construction. Denser materials like MDF and HDF tend to absorb sound waves more effectively, reducing distortion and enhancing clarity. This characteristic leads to improved bass response, making your audio experience richer and more immersive. In contrast, lighter materials may not provide the same level of sound dampening, potentially compromising sound quality.

Cost Implications of Different Materials

When evaluating material costs, it’s important to balance budget considerations with long-term value. While upfront costs for high-quality options like MDF may be higher, their durability and positive effect on sound quality often justify the investment. Choosing sub box material based solely on price may result in compromises that affect audio performance and longevity. Understanding the cost-benefit relationship of each material is vital in making the best choice for your subwoofer setup.

| Material | Sound Quality Impact | Material Costs |

|---|---|---|

| MDF | Excellent sound dampening; reduces distortion | Moderate to high |

| HDF | Superior clarity; strong bass response | High |

| Plywood | Decent dampening; lighter, less clear | Low to moderate |

| Fiberglass | Customizable; excellent in unique shapes | High |

Maximizing Bass Response: The Importance of Internal Bracing

When it comes to achieving superior bass response in your subwoofer, internal bracing is essential. This technique reinforces the structural integrity of the enclosure, ensuring that it can withstand the immense pressure generated by the subwoofer while minimizing any unwanted vibrations. Without proper internal bracing, the sides of the enclosure may flex, leading to distortion and a decrease in overall sound clarity.

Incorporating methods such as cross-bracing can significantly enhance your audio construction. By using strategically placed braces, you help stabilize the enclosure. This not only improves the sound fidelity of your subwoofer but also allows for deeper bass notes without sacrificing quality. The importance of internal bracing cannot be overstated, as it plays a vital role in delivering consistent and powerful bass response.

Understanding Acoustic Properties for Subwoofer Enclosures

When constructing subwoofer enclosures, understanding acoustic properties plays a vital role in achieving optimal sound quality. The way sound waves behave within the enclosure dictates how effective the subwoofer will be in producing rich bass tones. You can enhance your audio experience by focusing on resonance control techniques.

Resonance Control Techniques

Implementing effective resonance control is essential for minimizing unwanted sound distortions. You can employ various techniques to improve the overall performance of your subwoofer. Key methods include:

- Material Selection: Choosing dense materials for construction helps absorb vibrations, which can interfere with sound quality.

- Enclosure Geometry: The shape and size of the enclosure significantly affect how sound waves interact. Optimal designs can help prevent resonance buildup.

- Sound Dampening Additions: Utilizing materials like acoustic batting inside the enclosure can help dampen sound waves, enhancing clarity and depth.

Proper resonance control ensures sound waves do not clash, allowing for powerful and clean bass output. Through strategic design choices and material usage, you can create a subwoofer enclosure that takes full advantage of its acoustic properties, ultimately leading to a superior listening experience.

Conclusion

In summary, your choice of materials for subwoofer construction plays a pivotal role in determining overall sound quality and performance. Each material, from MDF to plywood, fiberglass, and polycarbonate, provides unique advantages tailored to different audio needs and preferences. Understanding these audio materials and their applications can significantly enhance your sound experience.

When designing a subwoofer box, it’s essential to consider factors like structural integrity, sound absorption capabilities, and the cost implications of various options. This careful assessment helps you achieve the desired audio enhancement you seek while ensuring lasting durability in your construction.

By investing your time and effort into selecting the right materials, you lay the groundwork for a high-quality audio environment. This attention to detail can transform your listening experience, allowing you to enjoy superior sound consistency and enriching moments of music and entertainment like never before.