To achieve a great bowl turn-out, start by choosing straight-grain wood that runs parallel to the shape, ensuring strength and visual appeal. Properly cut and prepare your blank with flat surfaces for secure mounting, and align the grain carefully depending on your design—either around or vertically. Sharp tools will make your cuts cleaner and easier, reducing tear-out. Mastering grain orientation and blank prep will set a solid foundation for professional results, so keep exploring these essential techniques.

Key Takeaways

- Select straight-grain wood with minimal defects for durability and aesthetic appeal.

- Orient the grain along the bowl’s circumference or vertically based on design needs.

- Ensure the blank is cut to appropriate size and has a flat surface for stable mounting.

- Properly prepare the blank to prevent cracking or warping during turning.

- Confirm grain alignment matches the intended bowl shape for optimal strength and appearance.

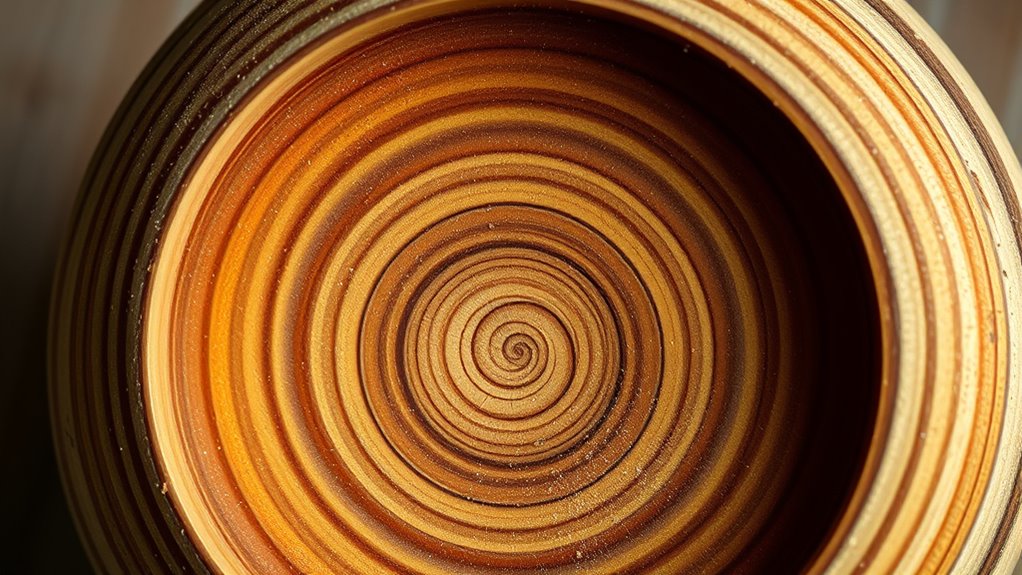

Have you ever wondered how a simple block of wood transforms into a smooth, functional bowl? The process begins long before the lathe starts spinning. It all starts with careful wood selection. You want to choose a piece with the right grain orientation and minimal defects. Look for wood with straight, even grain that runs parallel to the length of the blank. This helps guarantee stability and reduces the risk of cracking or warping later. Avoid knots, checks, or irregular grain, as these can weaken your finished piece and make shaping more difficult. The better your initial wood choice, the smoother your turning process will be and the more polished your final bowl will look. Additionally, understanding merchant services options can assist in sourcing quality materials more efficiently.

Once you’ve selected the right wood, the next essential step is preparing your blank. Proper blank preparation involves not only cutting it to the right size but also ensuring the grain runs correctly relative to the shape you want to achieve. You should orient the grain so that it runs along the bowl’s circumference or vertically, depending on your design. This orientation affects not only the aesthetics but also the strength and stability of your finished piece. Before mounting the blank on your lathe, make sure it’s flat on at least one side. This provides a stable surface for mounting and prevents wobbling during turning.

Tool sharpening plays a key role in bowl turning. Sharp tools make cleaner cuts, reduce tear-out, and allow you to work more efficiently and safely. Dull tools can cause rough surfaces and require more force, increasing the risk of slips or accidents. Regularly check and sharpen your gouges, scrapers, and parting tools before each session. Use a sharpening stone or jig to maintain consistent edge angles, ensuring your tools cut smoothly through the wood’s grain. When your tools are sharp, you’ll notice less resistance, a cleaner finish, and less frustration. Remember, the quality of your cut depends heavily on the sharpness of your tools and your ability to maintain that edge.

Frequently Asked Questions

What Types of Wood Are Best for Bowl Turning?

You should choose hardwoods like cherry, maple, or walnut for bowl turning because they offer beautiful grain patterns and durability. These wood species are easy to work with and provide a smooth finish. Avoid softwoods, as they tend to split or chip. Opt for woods with tight, consistent grain patterns to enhance the visual appeal of your bowl and guarantee stability during turning.

How Do I Prevent Tear-Out During Grain Cutting?

Think of cutting grain like steering a river; follow the current to prevent tear-out. To avoid tear-out during grain cutting, always pay attention to grain direction, cutting with the grain rather than against it. Use sharp tools, and take shallow cuts to reduce stress. Applying a scrape cut at the end of your pass also helps. These techniques ensure cleaner cuts and a smoother finish, keeping your bowl looking flawless.

What Tools Are Essential for Preparing Blanks?

To prepare blanks effectively, you need essential tools like a bandsaw or jigsaw for cutting, followed by quality sanders for smoothing surfaces. Use sanding techniques that gradually increase grit to avoid rough spots and tear-out. Consider finishing options like applying a sealant or oil after sanding to enhance durability and appearance. These tools and techniques guarantee your blanks are well-prepared, leading to better bowl turning results.

How Do I Choose the Right Grain Orientation?

Choosing the right grain orientation is like steering a garden’s seasonal stability; you want to match the grain to guarantee durability and visual harmony. Focus on grain matching—align the grain with the bowl’s shape to prevent warping. Consider the seasonality of the wood, selecting stable, well-seasoned blanks. By paying attention to these factors, you’ll create bowls that are both beautiful and enduring, much like a well-tended garden.

How Can I Correct a Warped Blank Before Turning?

To correct a warped blank, start by inspecting the grain alignment and identifying the warp direction. You can carefully re-mount the blank and apply gentle pressure or use clamps to straighten it, ensuring the grain runs properly during turning. Additionally, soaking the blank in water or using a damp cloth can help relax the wood fibers, aiding in warp correction. Always work slowly to prevent further distortion.

Conclusion

As you finish your bowl, remember that grain orientation is the heartbeat guiding your craft. Proper blank preparation is the steady hand that keeps your project balanced. Think of your turning process as a dance with the wood—each step in grain alignment and preparation sets the rhythm. When you respect these elements, your bowl becomes a harmonious symphony of skill and nature’s beauty, ready to be admired like a timeless melody carved in wood.